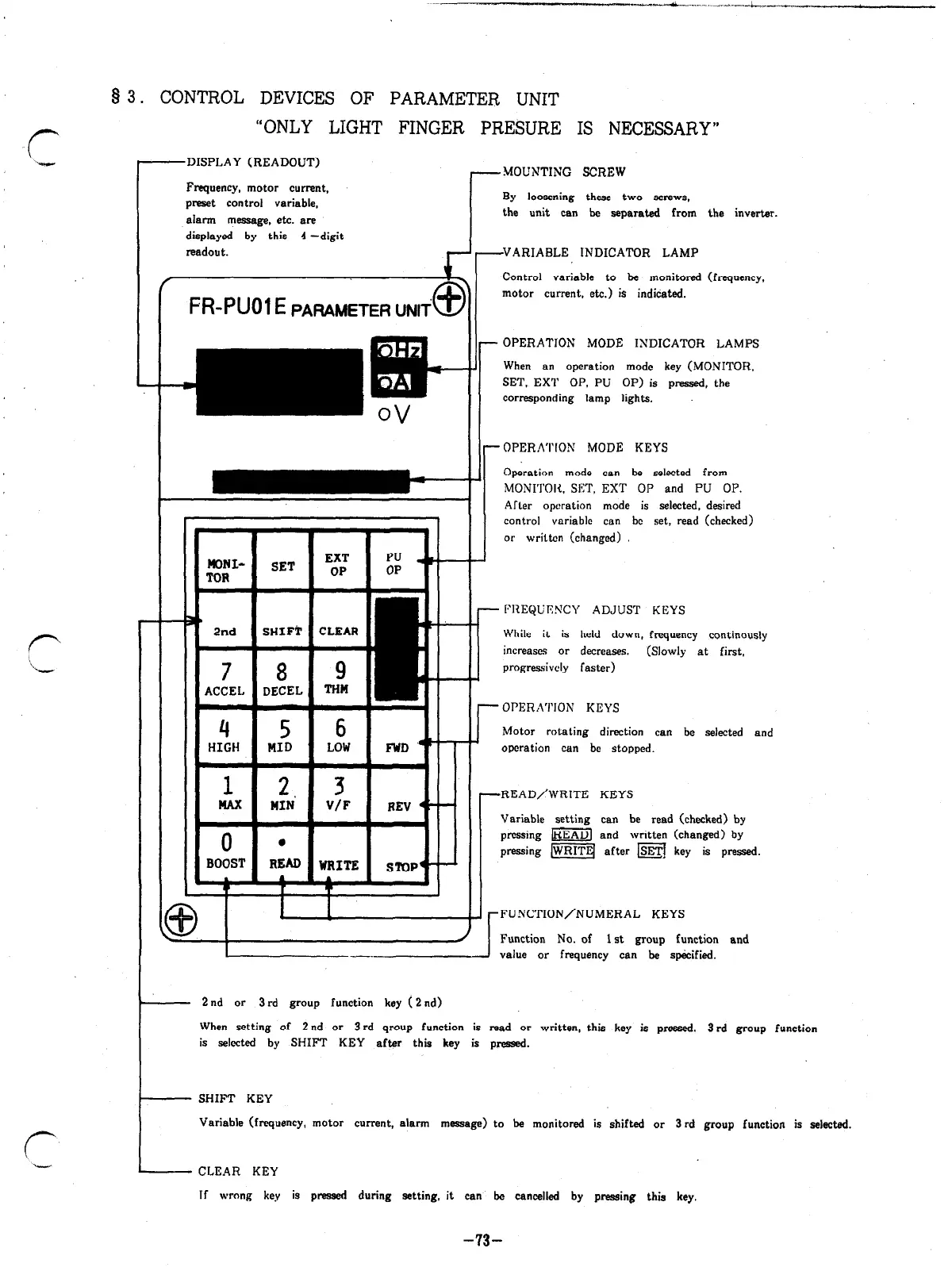

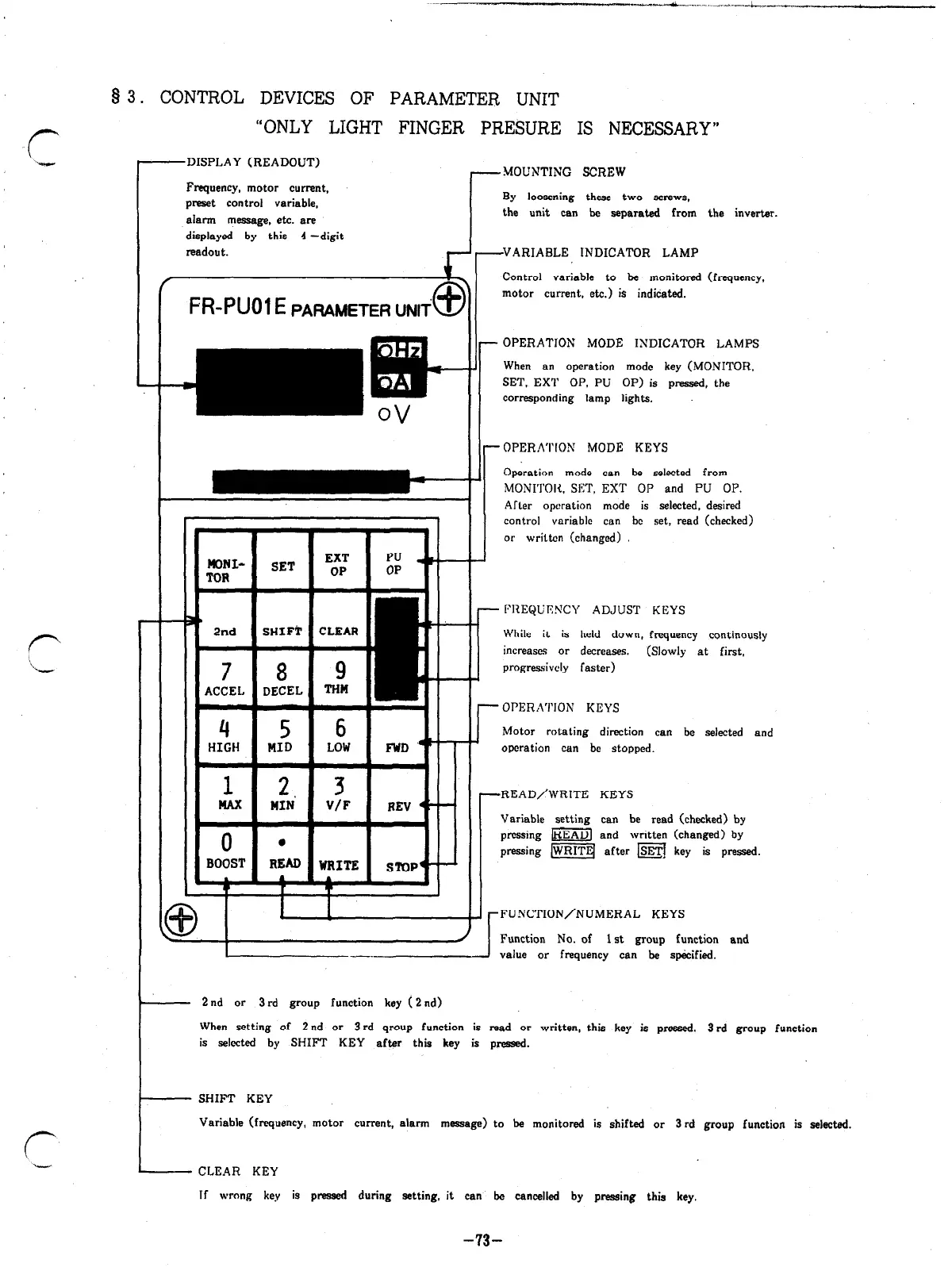

8 3. CONTROL DEVICES OF PARAMETER UNIT

“ONLY LIGHT FINGER PRESURE IS NECESSARY”

---DISPLAY (READOUT)

7MOUNTING SCREW

Frequency, motor current,

preset control variable,

alarm massage, etc. are

displayed by this 4 -digit

readout.

By loosening these two screws.

the unit can be separated from the inverter.

VARIABLE INDICATOR LAMP

r

i“

Control variable to be monitored

f

_

f%-PUOl E PARAMETER UNli

@

motor current. etc.) is indicated.

OPERATION MODE INDICATOR LAMPS

When an operation mode key (MONITOR,

SET, EXT OP. PU OP) is pressed. the

corresponding lamp lights.

I.

1

OPERATION MODE KEYS

Operation mode can be selected from

MONI’I’OH. WI’, EXT OP and PU OP.

Afler operation mode is selected. desired

control variable can bc set, read (checked)

or written (changed)

I

FliEQUI%‘CY ADJUST KEYS

While it is held down, frequency continously

increases or decreases. (Slowly at first,

progressively faster)

HIGH

r

OPERATION KEYS

Motor rotating direction can be selected and

operation can be stopped.

-READ/WRITE KEYS

I?

. . I

\I I

1-1

I

T I 1

I

\!

I

Variable setting can be read (checked) by

pmssing ml and written (changed) by

pressing [WRITE( after m key is pressed.

.FUNCTION/NUMERAL KEYS

d

I

Function No. of 1 st group function and

1 -

I

value or frequency can be specified.

- 2nd or 3rd group function key (2 nd)

When setting of 2nd or 3 rd qroup function is read or written, this key is pressed. 3 rd group function

is selwted by SHIFT KEY after this key is pressed.

- SHIFT KEY

Variable (frequency, motor current, alarm message) to be monitored is shifted or 3rd group function is selected.

- CLEAR KEY

If wrong key is pressed during setting, it can be cancelled by pressing this key.

-73-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...