12

12-15

3. Oil Pressure Measurement

Service standards

Tightening torque (Unit: N·m {kgf·m})

Lubricant and/or sealant

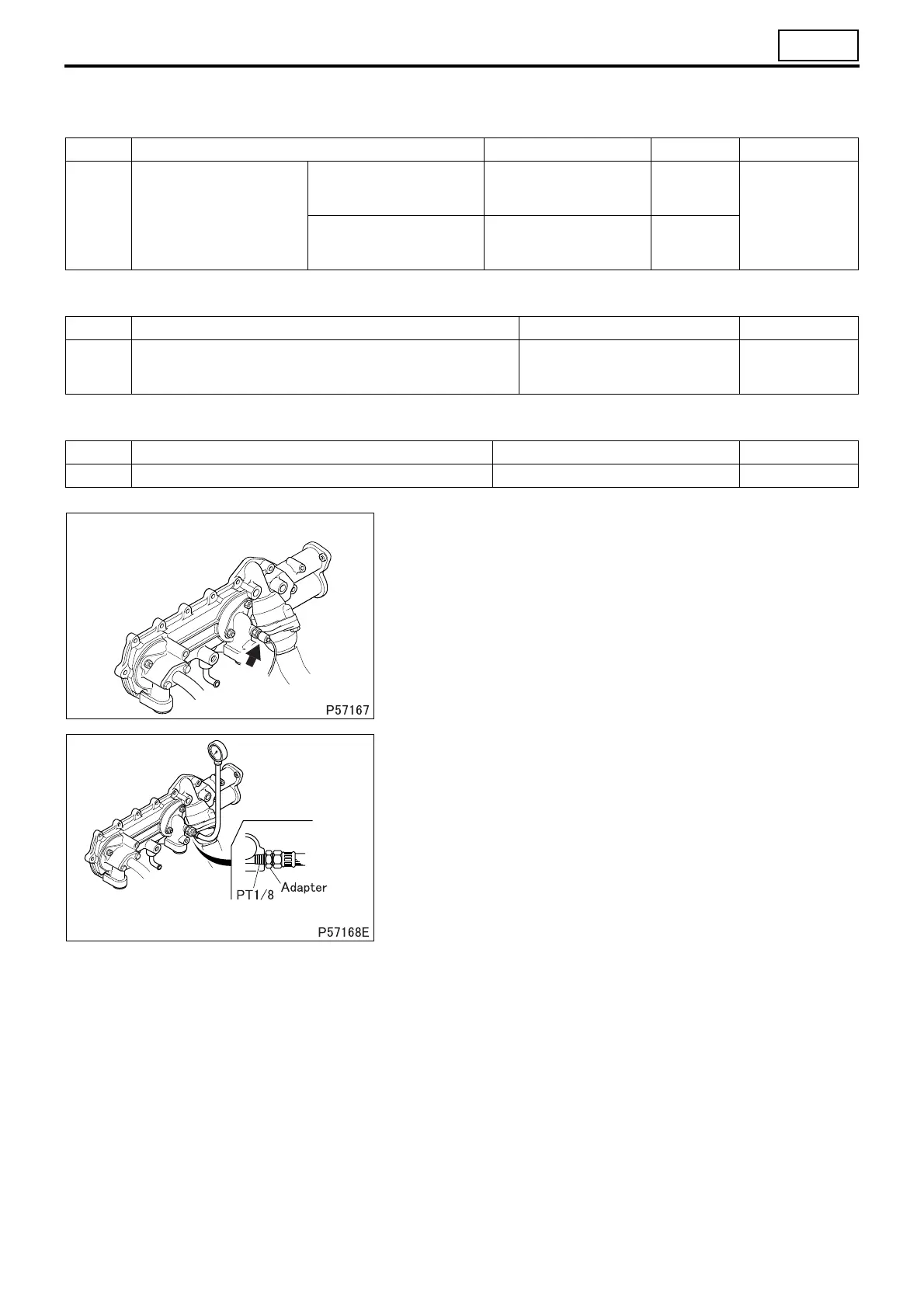

• Remove the engine oil pressure switch.

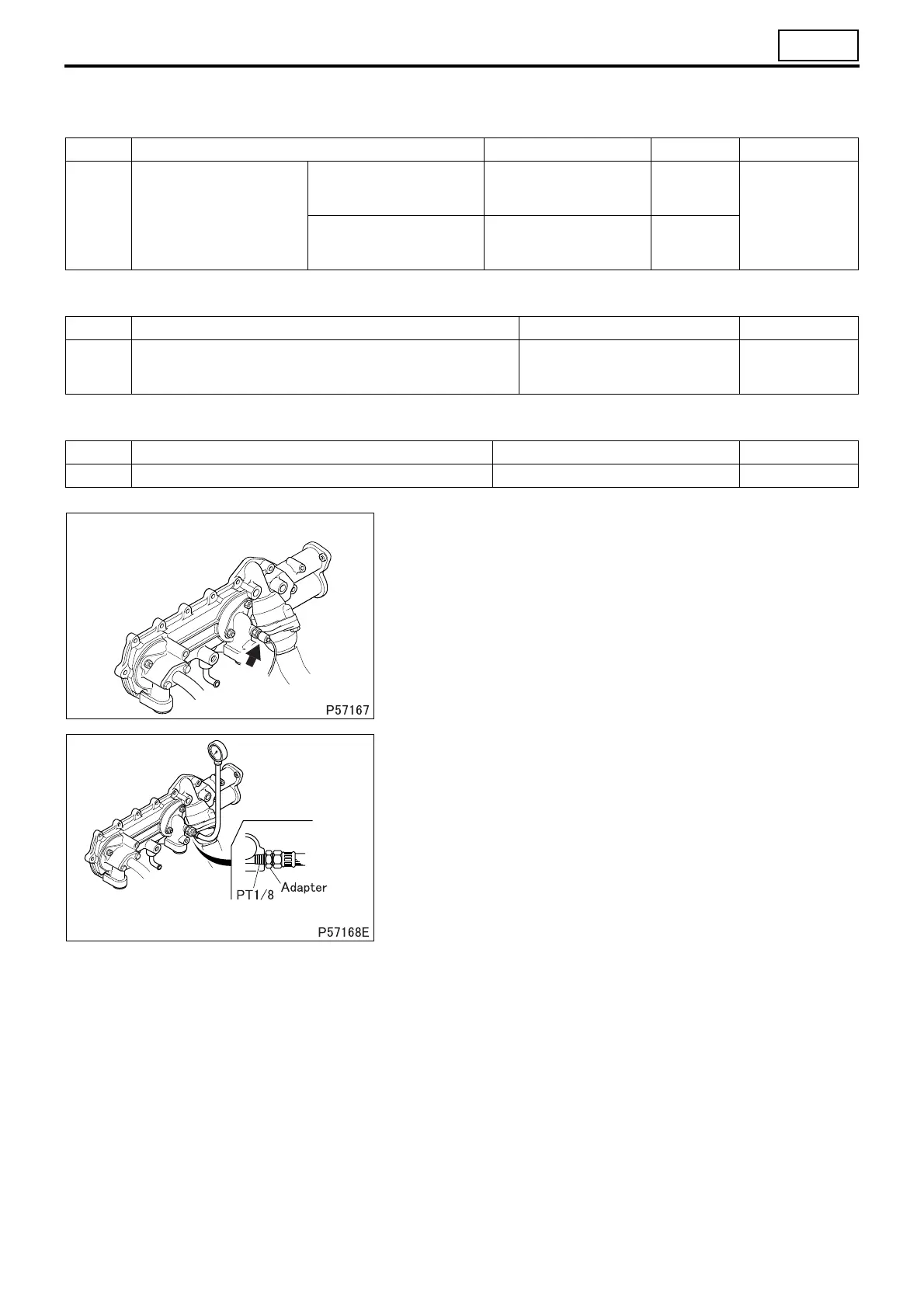

• Using an adapter, connect an oil pressure gauge to the engine

oil pressure switch mounting hole.

• Warm up the engine until the oil temperature reaches 70 to

90°C.

• Measure the oil pressure while running the engine at a minimum

speed and then at maximum speed, both under no load.

• If the measurements are below the specified limits, overhaul the

lubrication system.

• After taking the measurements, install the engine oil pressure

switch using the following procedure:

• Cool the engine adequately so that the engine oil pressure

switch can be tightened with an accurate tightening torque.

• Apply sealant to the threaded portion of the engine oil pres-

sure switch.

• Tighten the engine oil pressure switch to the specified torque.

Location Maintenance item Standard value Limit Remedy

–

Oil pressure

(oil temperature at 70 to

90°C)

No-load minimum speed

195 kPa

{2.0 kgf/cm

2

}

98 kPa

{1.0 kgf/

cm

2

}

Inspect

No-load maximum speed

295 to 490 kPa

{3 to 5 kgf/cm

2

}

195 kPa

{2.0 kgf/

cm

2

}

Mark Parts to be tightened Tightening torque Remarks

– Engine oil pressure switch 12 {1.2}

• Sealant

• With cold en-

gine

Mark Points of application Specified lubricant and/or sealant Quantity

– Engine oil pressure switch threads ThreeBond 1215 As required

Loading...

Loading...