11

11-53

Inspection procedure

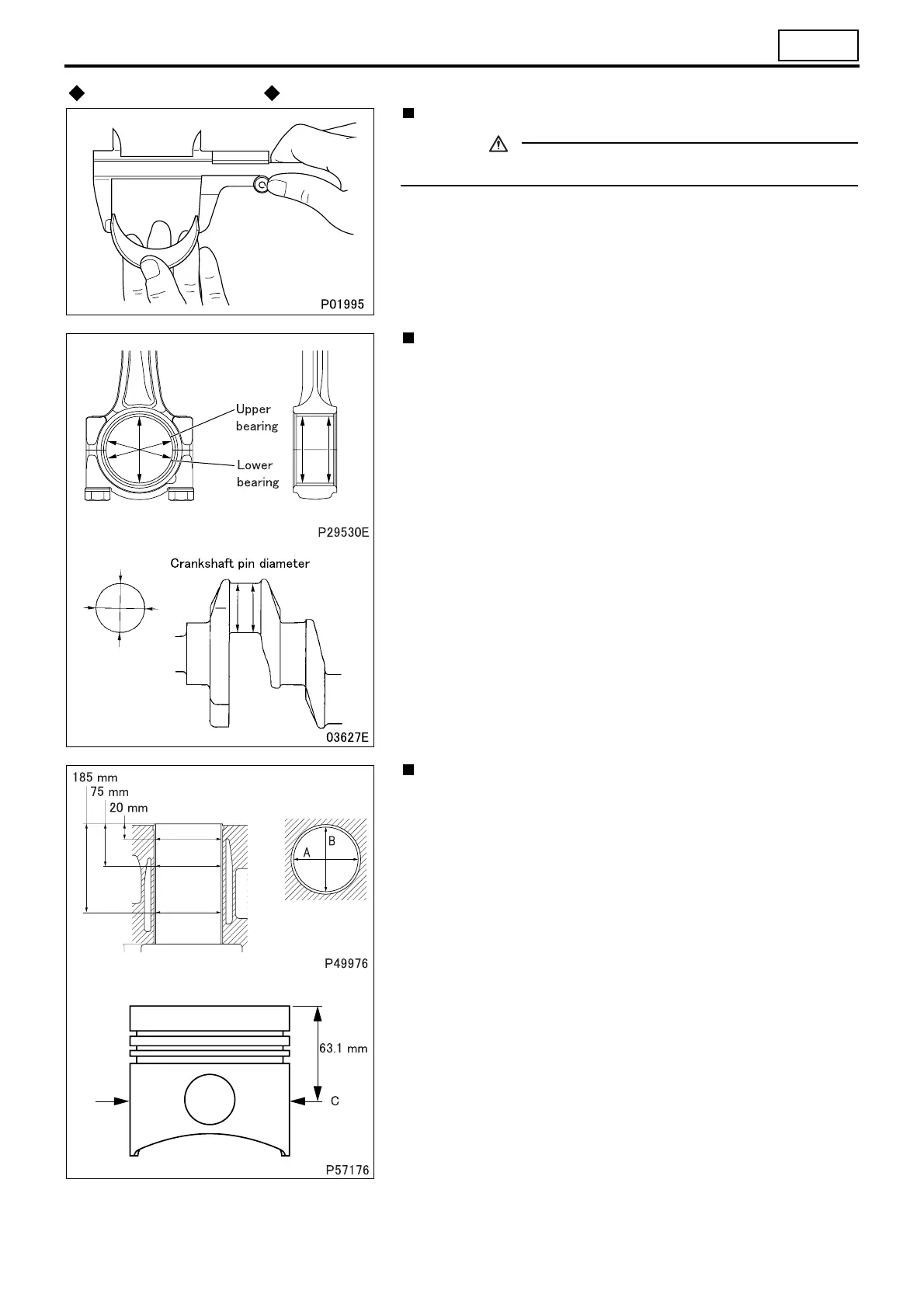

Inspection: Connecting rod bearing span when free

CAUTION

• Do not attempt to manually expand the bearings.

• If the measurement is less than the limit, replace upper and low-

er bearings as a set.

Inspection: Connecting rod bearing-to-crankshaft oil clear-

ance

• Fit the lower bearing to the connecting rod cap and the upper

bearing to the connecting rod, then tighten the bolts to a torque

of 29 N

·m {3.0 kgf·m}.

• Measure the inside diameter of the bearing and the diameter of

the crankshaft pin.

• If the clearance exceeds the limit, replace the defective part(s).

• If a bearing has to be replaced with an undersized one, machine

the crankshaft pin to the specified undersize diameter. (See the

CRANKSHAFT section.)

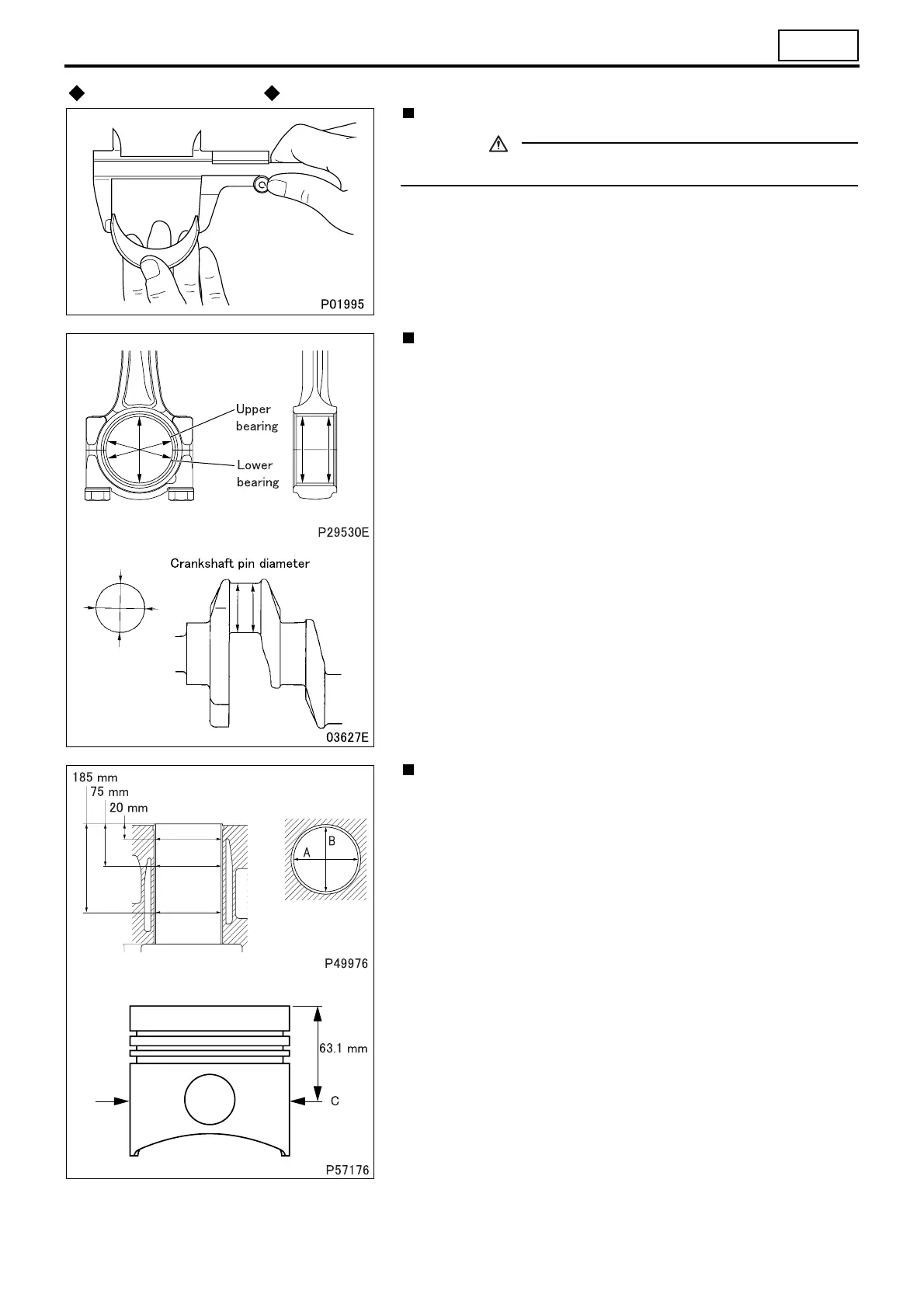

Inspection: Piston-to-cylinder liner clearance

• If the measurement is not within the standard value range, re-

place the defective part(s).

A: Cylinder bore measurement (in direction of crankshaft axis)

B: Cylinder bore measurement (in direction perpendicular to

crankshaft axis)

C: Piston diameter measurement (in direction perpendicular to

piston pin hole)

Loading...

Loading...