11-14

1. Measuring Compression Pressure

Service standards

Special tools (Unit: mm)

• A drop in compression pressure can be used as a guide to determine when the engine should be overhauled.

• Measure the compression pressure at regular intervals. Keeping track of its transitions can provide a useful tool

for troubleshooting. On new vehicles and vehicles with newly replaced parts, the compression pressure will be

somewhat higher depending on the break-in condition of piston rings, valve seats, etc., but this will return to nor

-

mal as the parts wear down.

• Before the compression measurement, confirm that the engine oil, starter, and battery are in normal condition.

• Place the vehicle in the following conditions.

• Warm up the engine until the coolant temperature reaches approximately 80 to 90°C.

• Turn off the lights and auxiliaries.

• Place the transmission in neutral.

• Place the steering wheel in the straight-ahead position.

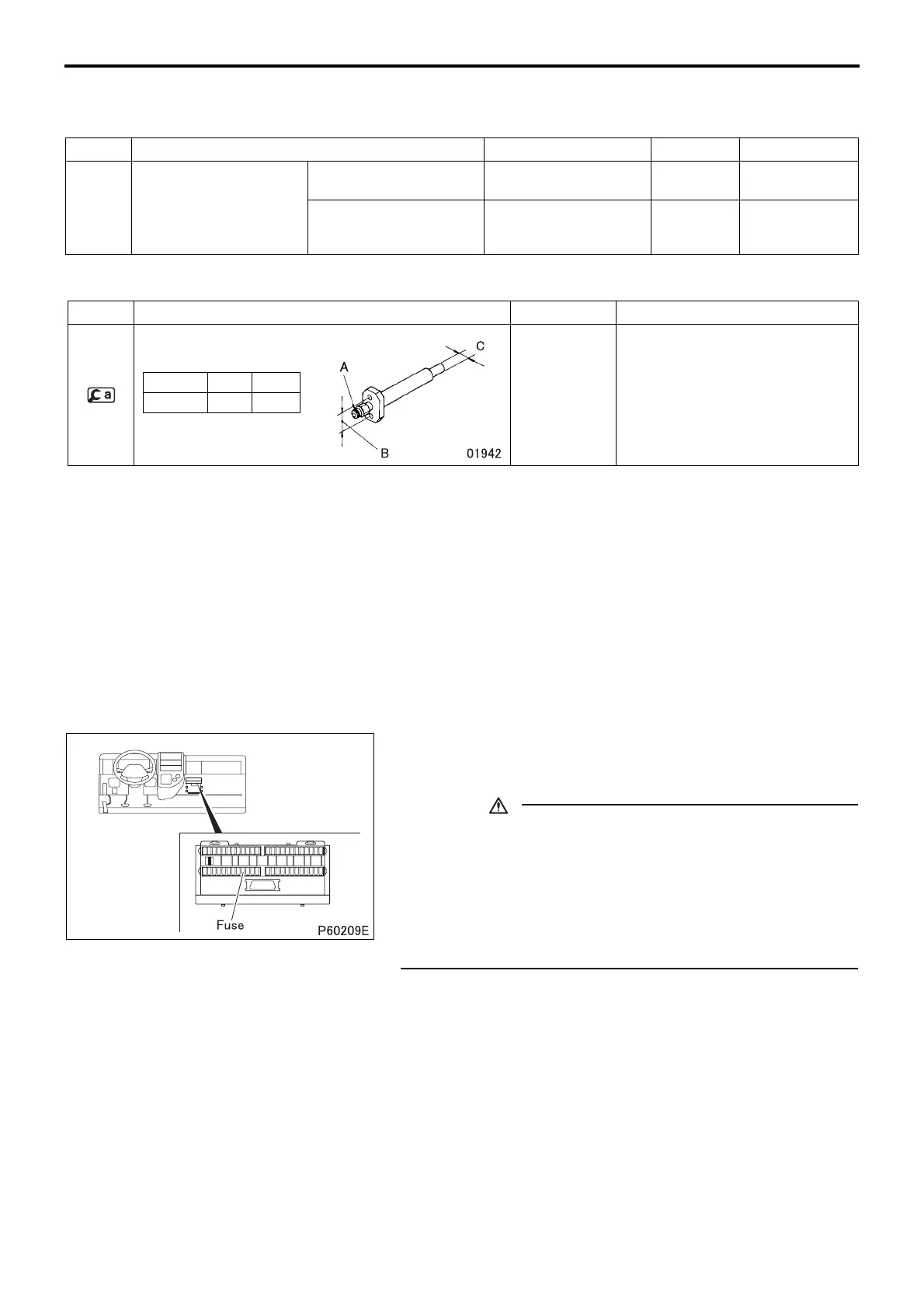

• Remove the fuse (M9) to prevent fuel from being injected when

the engine is cranked by the starter.

CAUTION

• When cranking the engine, never shut off the power to the

engine electronic control unit by disconnecting the engine

electronic control unit connector or the like.

• If the engine is cranked while shutting off the power to the

engine electronic control unit, the electronic control unit

cannot control the supply pump and this may cause failure

to the pump.

Location Maintenance item Standard value Limit Remedy

– Compression pressure

Each cylinder (at 250 rpm)

3100 kPa

{32 kgf/cm

2

}

2400 kPa

{24 kgf/cm

2

}

Inspect

Cylinder-to-cylinder pres-

sure difference

–

500 kPa

{5 kgf/cm

2

}

or less

Inspect

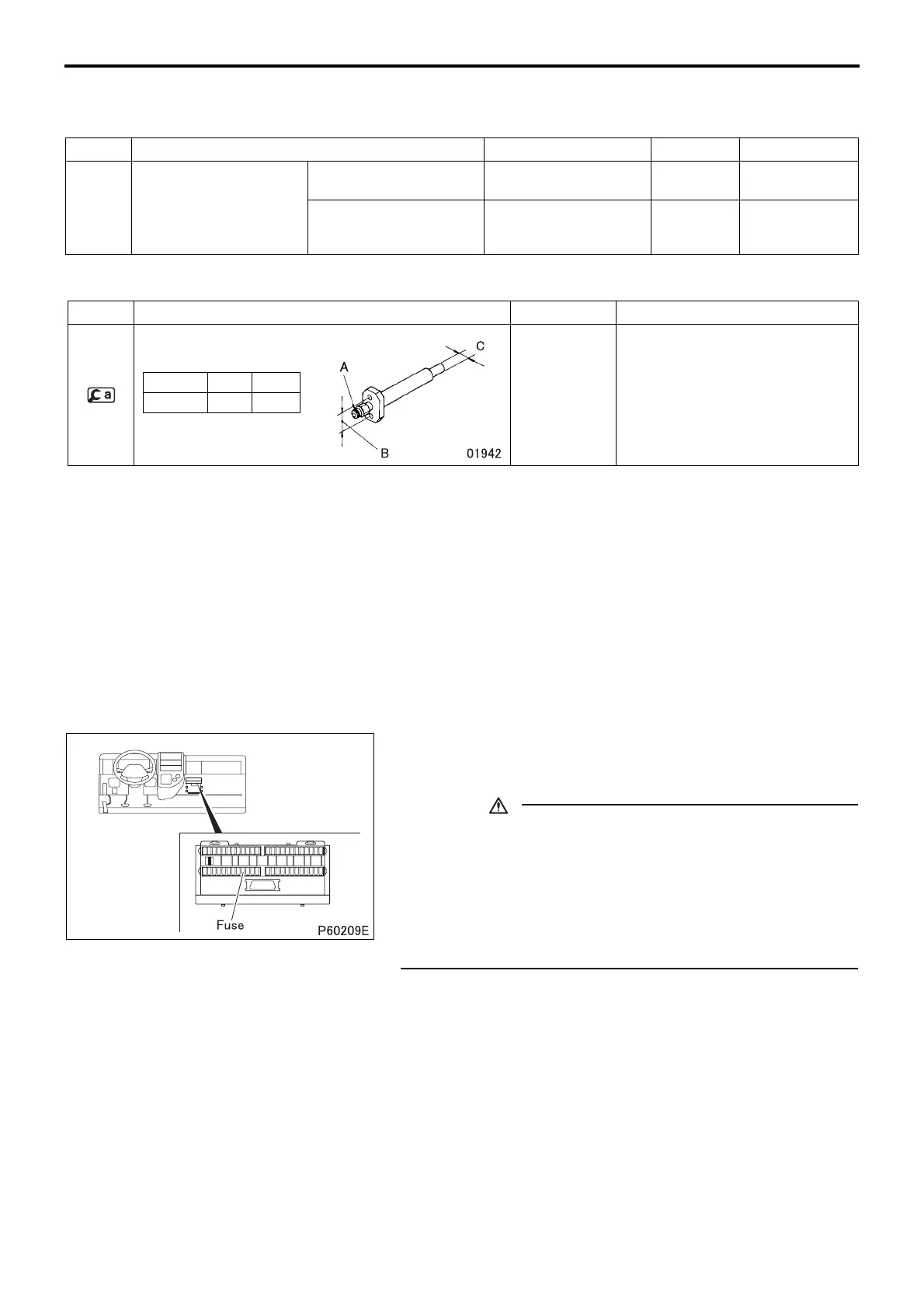

Mark Tool name and shape Part No. Application

Compression gauge adapter

MH063853 Measuring compression pressure

ABC

M14 × 1.5 58 φ7.2

ON-VEHICLE INSPECTION AND ADJUSTMENT

Loading...

Loading...