i

APPLICATION

EXAMPLES

I

IWeldingRobot

I

I

Robot control system application

1

Items controlled

Positioning mechanism, spot welder, welding gun and inverter

Overall aim

After the welding points are determined by teaching, automatic welding is done in a

playback mode,

Advantages

A

low

cost and simple welding robot is possible, without the need for a high cost

specialized controller.

Method

of

control description

When the welding machine

is

manually operated in "teaching" mode, the position is

detected by the position control module AlSD7142. At stop, the position is stored

in a data register. Thereafter, only the welding points are taught.

In "playback" mode, position data is read out in the correct order and the welder is

positioned and performs welding. During positioning the welder speed is controlled

by the inverter. Stopping accuracy is approximately

+/-

0.5

mm, and accumulative

errors have been eliminated by the sequence program.

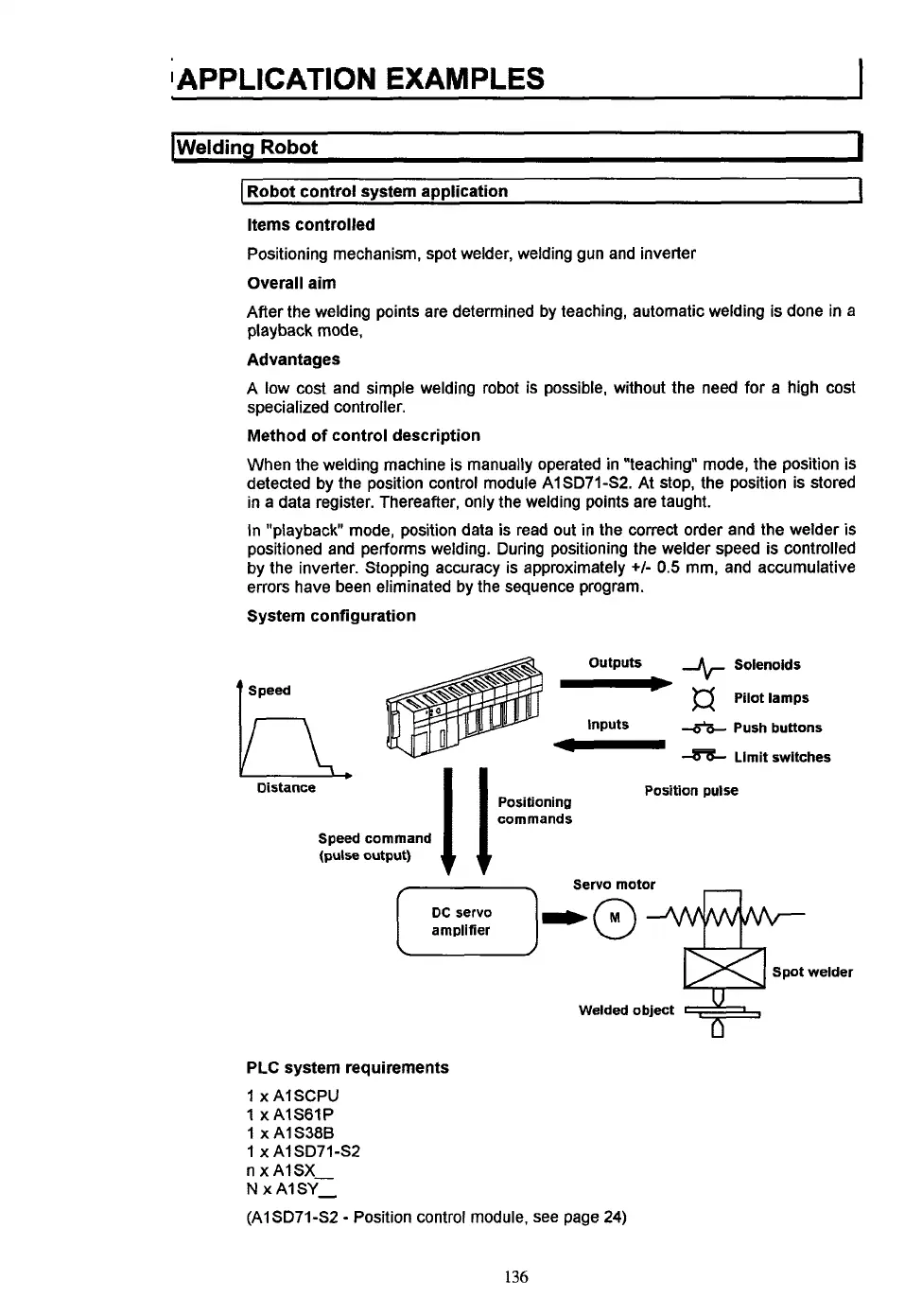

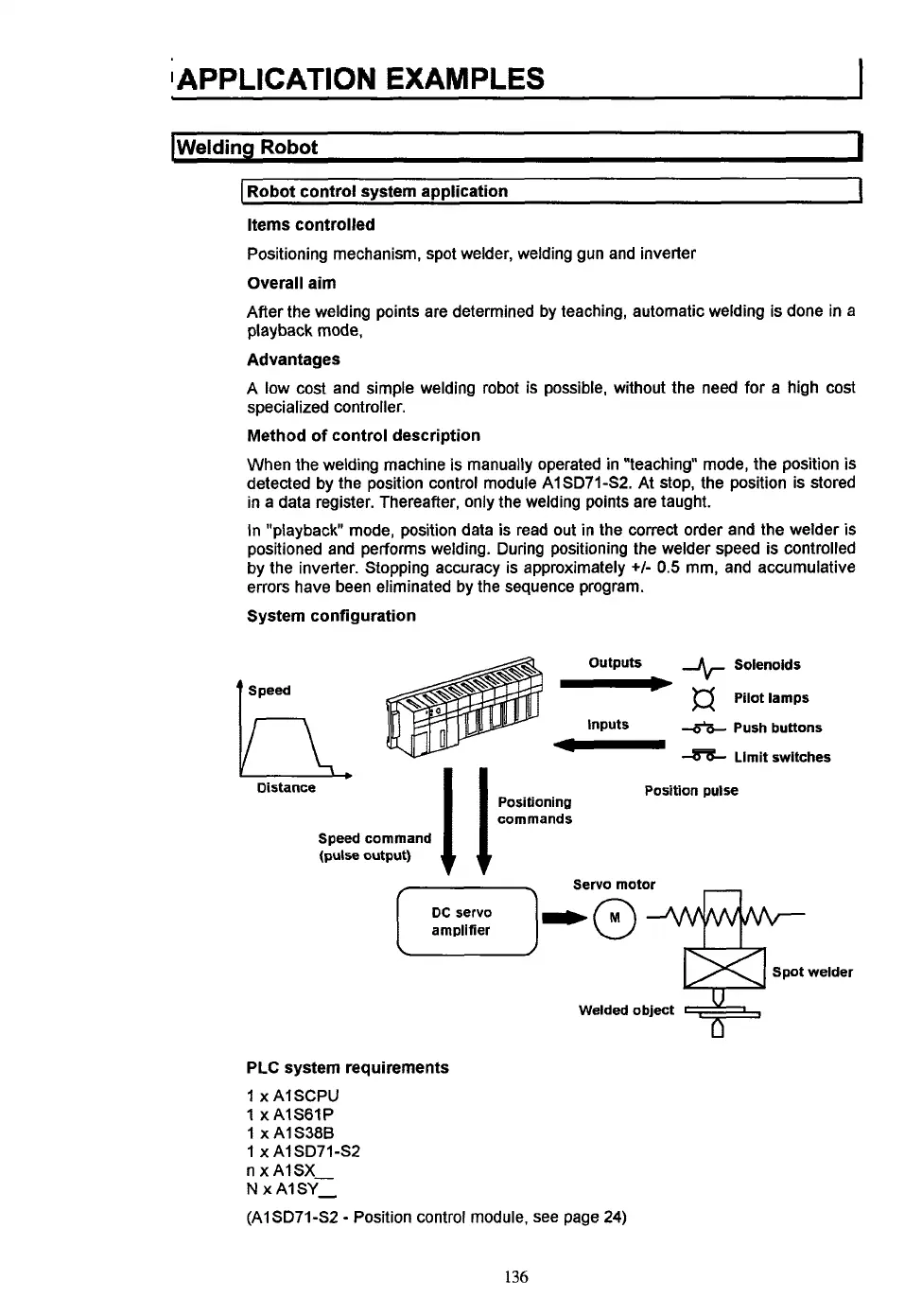

System configuration

Distance

Speed

(pulse

outputs Solenoids

a

Pilot lamps

-

inputs

&

Push buttons

-

Limitswitches

Servo motor

DC

servo

amplifier

I)-

@

w elder

Welded object

PLC

system requirements

1 x AISCPU

1

xAIS6IP

1

x

AI

S38B

n

x

AISX-

N

x

AI

SY-

(AI SD71-S2

-

Position control module, see page

24)

1

xAISD~I-SZ

136

Loading...

Loading...