5 - 52

MELSEC-Q

5 DATA USED FOR POSITIONING CONTROL

Setting value, setting range

Setting value buffer memory

address

Item

Value set with peripheral

device

Value set with sequence program

Default

value

Axis 1 Axis 2 Axis 3 Axis 4

Pr.53

OP shift amount

The setting value range differs depending on the "

Pr.1

Unit setting".

Here, the value within the [Table 1] range is set.

[Table 1] on next page

0

84

85

234

235

384

385

534

535

Pr.54

OPR torque limit value

1 to 300 (%) 1 to 300 (%) 300 86 236 386 536

Pr.55

Deviation counter

clear signal output

time

1 to 65535 (ms)

1 to 65535 (ms)

1 to 32767:

Set the decimal value as it is.

32768 to 65535:

Convert into hexadecimal and set.

11 87 237 387 537

0 : OPR speed 0

Pr.56

Speed designation

durin

OP shif

1 : Creep speed 1

0 88 238 388 538

Pr.57

Dwell time during

OPR retry

0 to 65535 (ms)

0 to 65535 (ms)

0 to 32767 :

Set as a decimal

32768 to 65535 :

Convert into hexadecimal and set

0 89 239 389 539

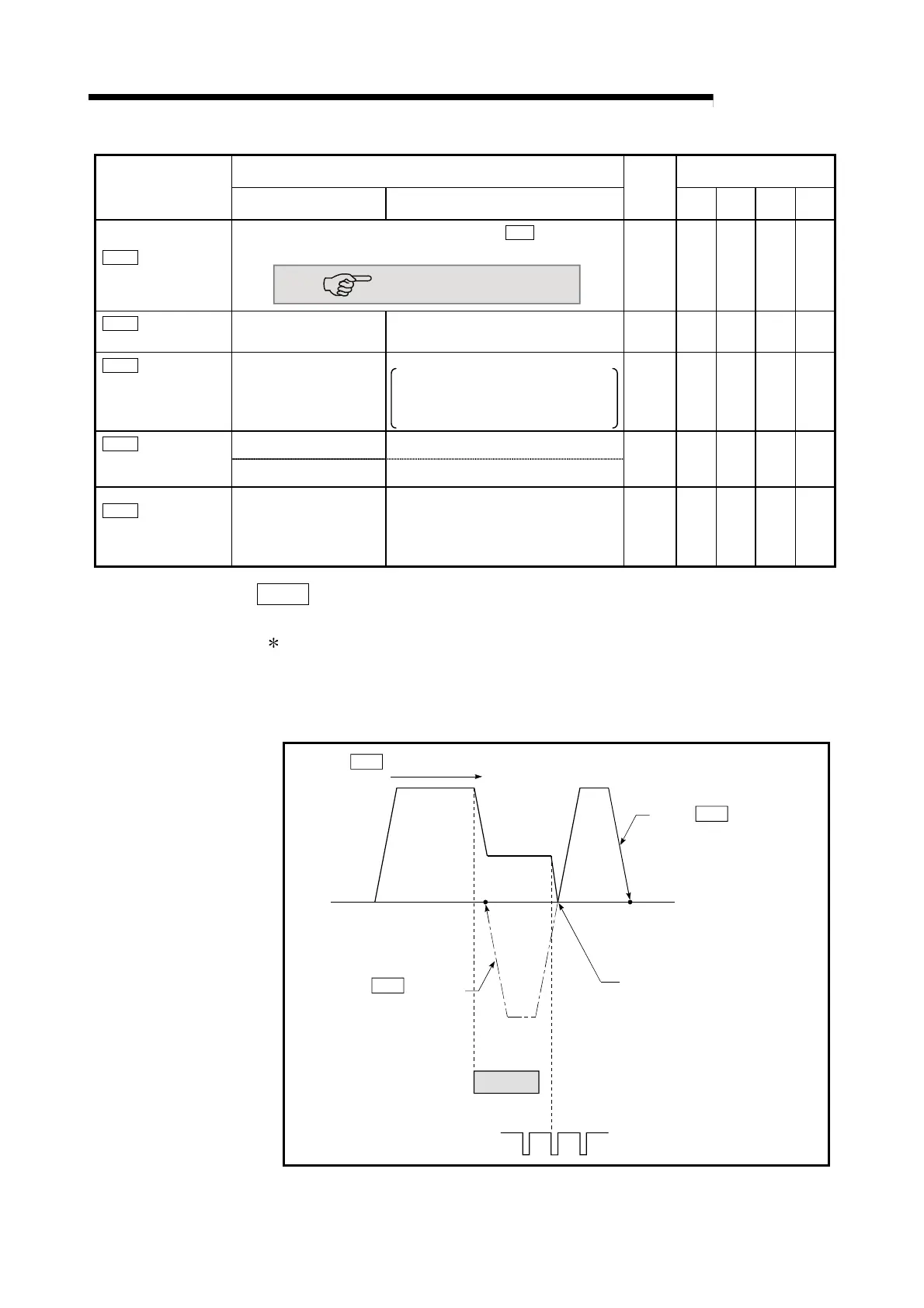

Pr.53

OP shift amount

Set the amount to shift (move) from the position stopped at with machine OPR.

The OP shift function is used to compensate the OP position stopped at with

machine OPR.

If there is a physical limit to the OP position, due to the relation of the near-point

dog installation position, use this function to compensate the OP to an optimum

position.

OPR direction

When " OP

shift amount" is positive

Shift point

Shift point

When " OP

shift amount" is negative

Start point

Shift after deviation

counter clear is canceled

Near-point dog signal

Zero signal

Pr.53

Pr.53

Pr.44

Loading...

Loading...