143 / 195

Service Manual Mitsubishi SL-Series diesel engines

Version 08/2004

INSPECTION

ENGLISH

LUBRICATION SYSTEM

LUBRICATION SYSTEM

37 INSPECTION

37.1 Oil pump

Visually check the pump for rough rotation or other

defects. Replace the pump assembly if defective.

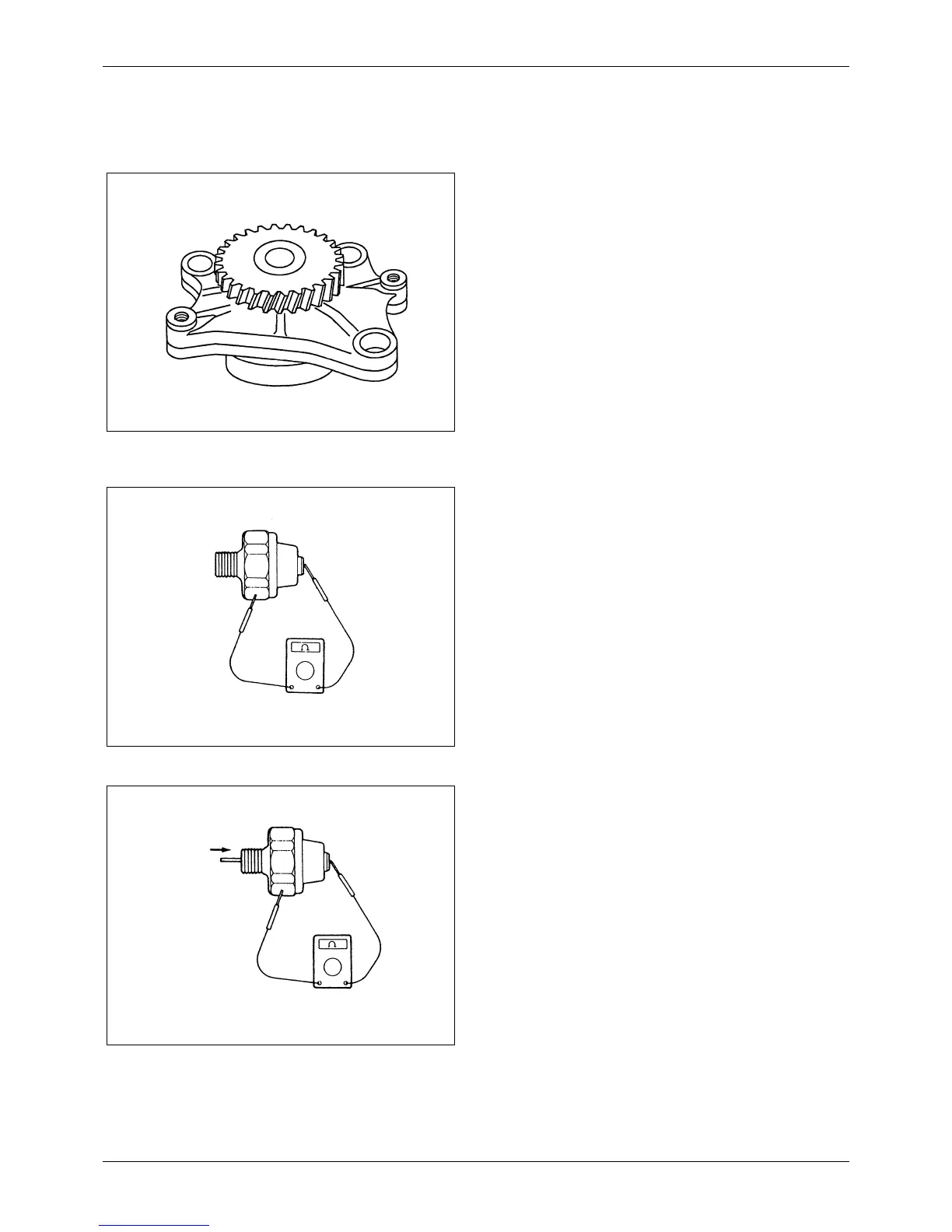

37.2 Oil pressure switch

1. Test for continuity between the terminal and body

with an ohmmeter as shown in the illustration. No

continuity is the cause for replacing the switch.

2. Insert a small diameter bar into the oil hole in the

switch and lightly push it in to test for no continuity

as shown in the illustration. Any continuity is the

cause for replacing the switch.

3. Apply a pressure air of 0.5 kgf/cm

2

(7 psi) [49 kPa]

to the switch through the oil hole to test for no

continuity. Any continuity is the cause for replacing

the switch. Also, check for air leaks. Any air leak

is an indication of a ruptured diaphragm. In such a

case, replace the switch.

Figure 210 Checking oil pump

Figure 211 Testing oil pressure switch (1)

Figure 212 Testing oil pressure switch (2)

Small diameter bar

Loading...

Loading...