78 / 195

Service Manual Mitsubishi SL-Series diesel engines

Version 08/2004

ENGLISH

CYLINDER BLOCK, CRANKSHAFT,

PISTONS AND OIL PAN

INSPECTION

78 / 195

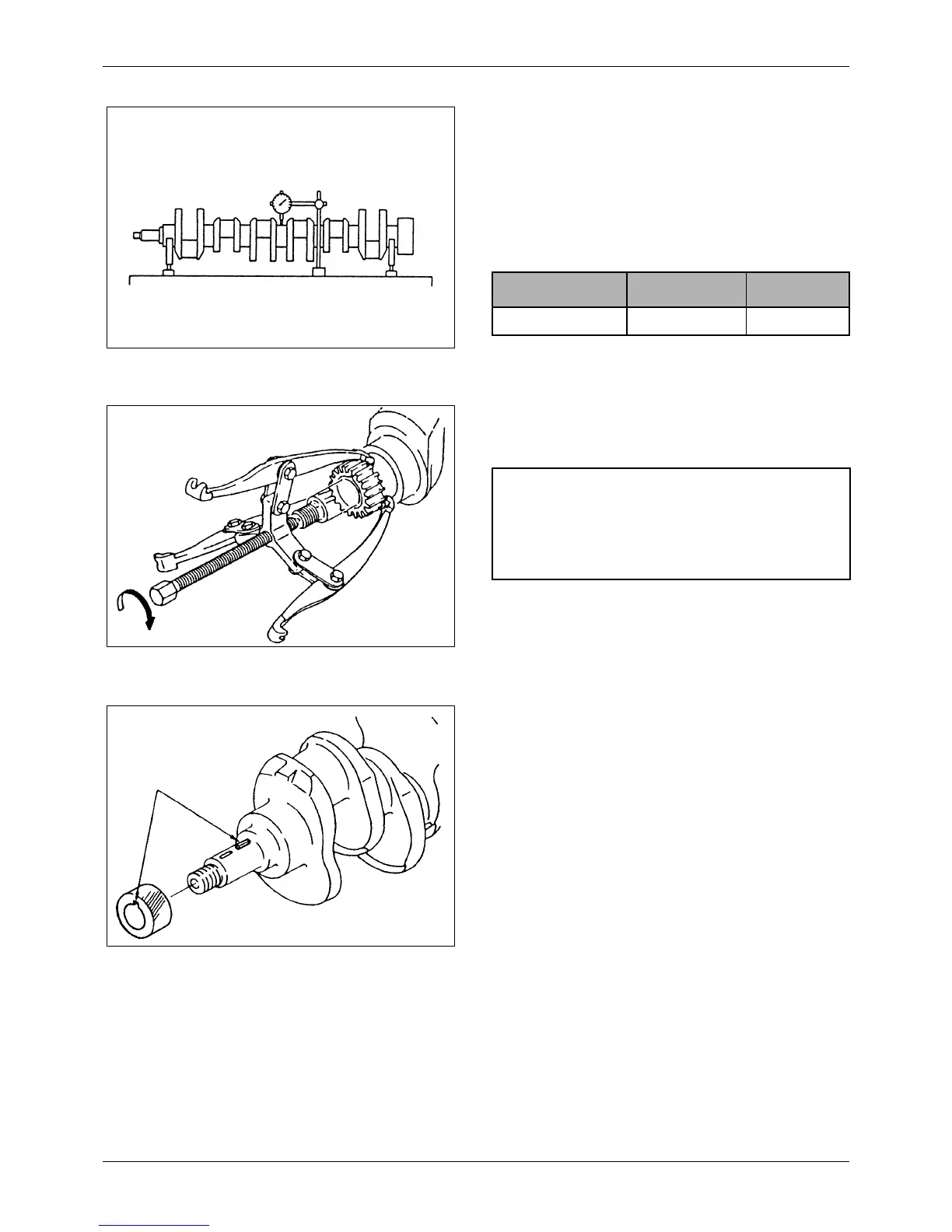

3. Runout

Support the crankshaft on its front and rear jour-

nals in V-blocks or in a lathe and check runout at

the center journal with a dial indicator as shown in

the illustration. Depending on the amount of

runout, repair the crankshaft by grinding or by

straightening with a press. If runout exceeds the

limit, replace the crankshaft.

Unit: mm (in.)

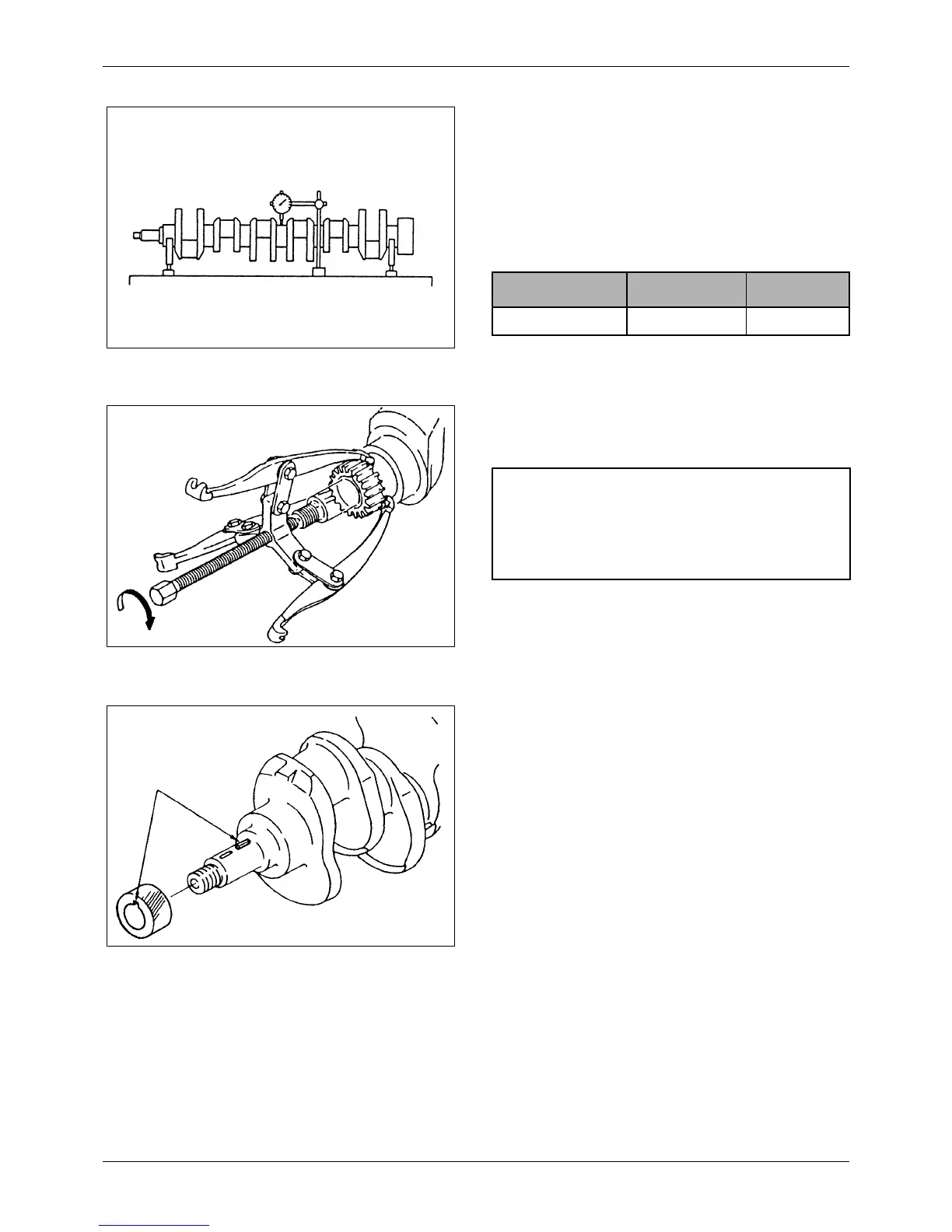

4. Crankshaft gear removal

Use a gear puller to remove the gear from the

crankshaft

5. Crankshaft gear installation

1) Install the key in position on the crankshaft.

2) Install the gear in position with its keyway in

alignment with the key as shown in the

illustration.

Figure 107 Checking crankshaft runout

Item Standard Limit

Crankshaft runout 0.025 (0.000 98) 0.05 (0.002 0)

Figure 108 Removing crankshaft gear

NOTE

Do not remove the gear unless the gear or crankshaft

is defective.

Figure 109 Installing crankshaft gear

To be aligned

Loading...

Loading...