24

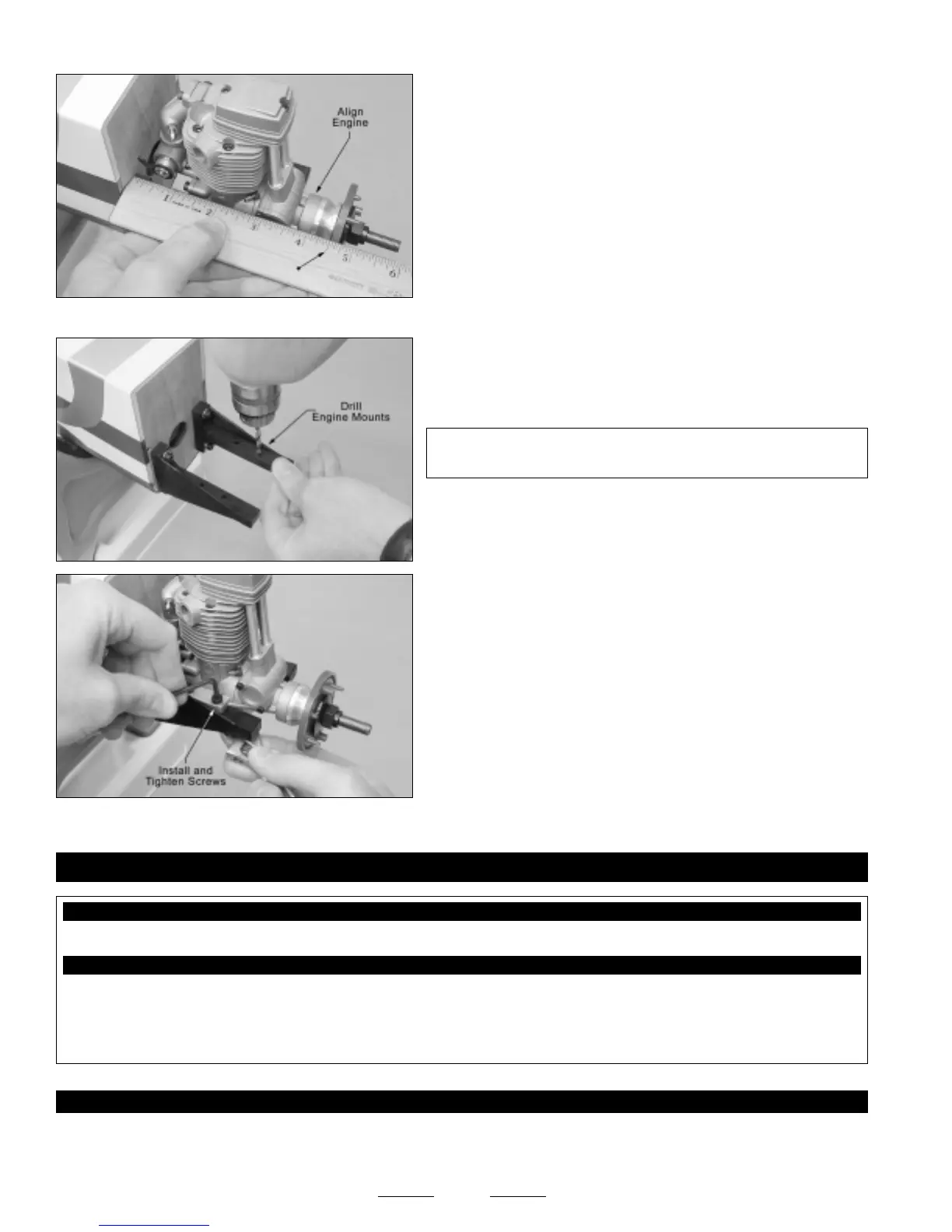

❑ With the fuselage upside down, set the engine onto the engine

mounting beams.

❑ Using a ruler, measure the distance from the firewall to the back of

the spinner backplate. Adjust the depth of the engine so that the

measurement is 4-1/2".

❑ Using a pencil, carefully mark the locations of the engine mounting holes onto the engine mounting beams.

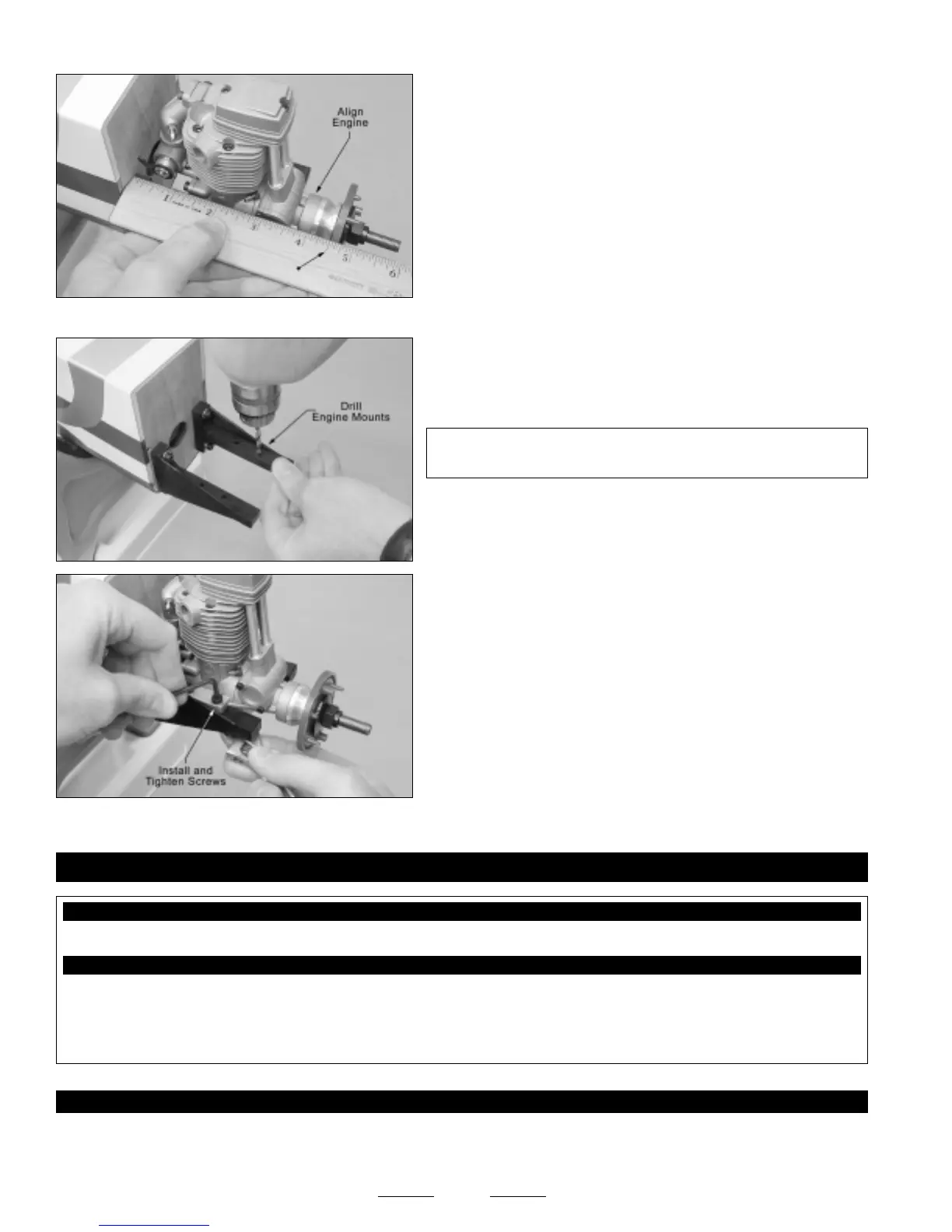

❑ Remove the engine and drill 3/32" diameter pilot holes through the

engine mounting beams at the marks you drew.

✦✦

✦✦

✦IMPORTANT

✦✦

✦✦

✦ Be careful that you drill the holes straight down

and not at an angle.

❑ Carefully enlarge the 3/32" diameter pilot holes, using a 5/32"

diameter drill bit.

❑ Install the engine using four M4 x 25mm socket-cap screws, eight

M4 flat washers and four M4 lock nuts.

☞

Tighten the screws and lock nuts firmly to hold the engine securely

into place.

❑ Kwik Bond Thin C/A

❑ # 1 & # 2 Phillips Head Screwdrivers

❑ Wire Cutters

❑ Needle Nose Pliers

❑ Electric Drill

❑ 1/16" & 5/64" Drill Bits

❑ Ernst Airplane Stand

❑ Ruler

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 13: THROTTLE CONTROL SYSTEM INSTALLATION

❑ (1) 13-1/4" Plain Wire w/Z-Bend

❑ (1) Adjustable Pushrod Connector w/Machine Screw & Nut

STEP 1: INSTALLING THE THROTTLE SERVO

❑ Install the rubber grommets and brass collets onto your throttle servo, making sure to install the collets with the flanges toward

the bottom of the servo.

Continued On Next Page

☛☛

☛☛

☛

Loading...

Loading...