32

❑ Kwik Bond Thin C/A

❑ # 1 Phillips Head Screwdriver

❑ Wire Cutters

❑ Needle Nose Pliers

❑ Excel Modeling Knife

❑ Electric Drill

❑ 1/16" & 5/64" Drill Bits

❑ Ernst Airplane Stand

❑ Ruler

❑ Pencil

❑ Masking Tape

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 16: RUDDER CONTROL SYSTEM INSTALLATION

❑ (2) 38-1/2" Threaded Wires w/90º Bends

❑ (2) Nylon Control Horns (w/o Backplates)

❑ (2) Nylon Clevises

❑ (2) Nylon 90º Snap-Keepers

❑ (4) M2 x 12mm Machine Screws

❑ (4) M2 Flat Washers

❑ (4) M2 Hex Nuts

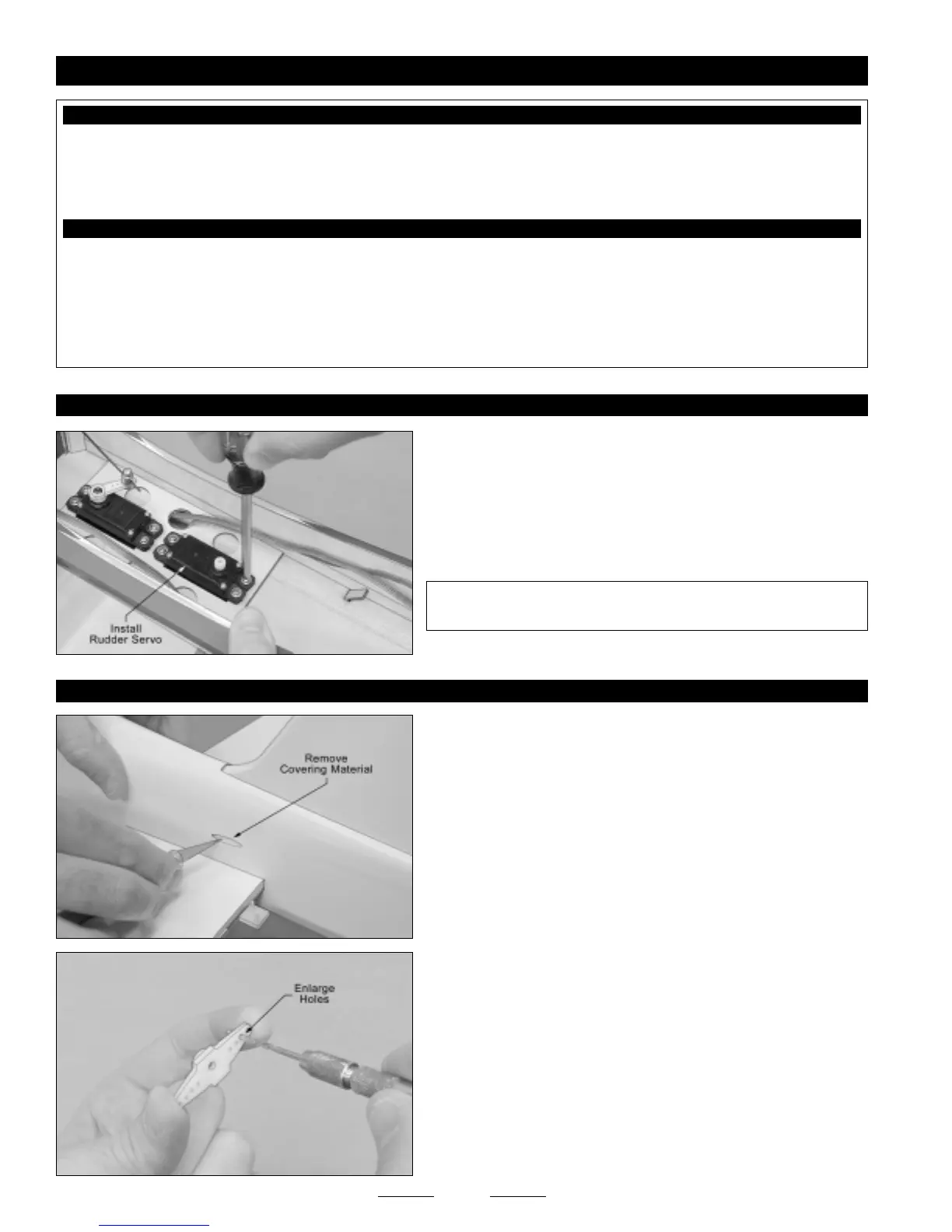

STEP 1: INSTALLING THE RUDDER SERVO

❑ Install the rubber grommets and brass collets onto your rudder servo,

making sure to install the collets with the flanges toward the bottom of

the servo.

❑ Install the rudder servo into the plywood servo tray, making sure to

drill 1/16" diameter pilot holes for the mounting screws.

✦✦

✦✦

✦IMPORTANT

✦✦

✦✦

✦ The servo output shaft should be toward the back

of the fuselage, as shown.

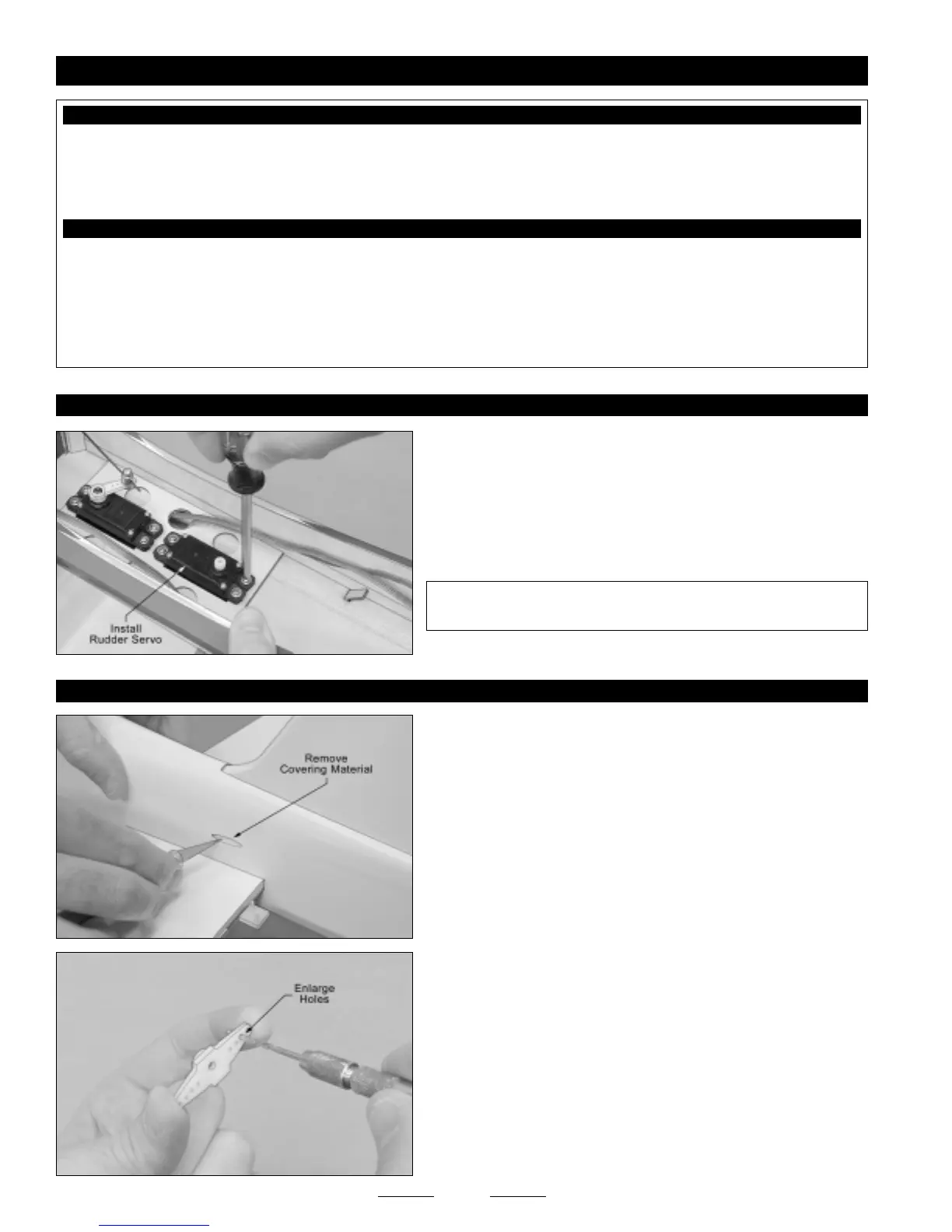

STEP 2: INSTALLING THE RUDDER PUSHROD ASSEMBLY

❑ Using a modeling knife, cut away and remove the covering material

from over the rudder pushrod exit hole in each side of the fuselage. The

holes are located 5-1/4" in front of the rudder hinge line and 5/8" above

the top of the horizontal stabilizer.

❑ Using a modeling knife, cut away two arms from a "4-point" servo horn.

❑ Enlarge the hole in each arm that is 9/16" out from the center of the

servo arm, using a 5/64" diameter drill bit.

Continued On Next Page

☛☛

☛☛

☛

Loading...

Loading...