SCH2 Technical Manual TSP016.doc Issue 3.0 – January 2005

Money Controls 2005. All rights reserved.

Page 50 of 61

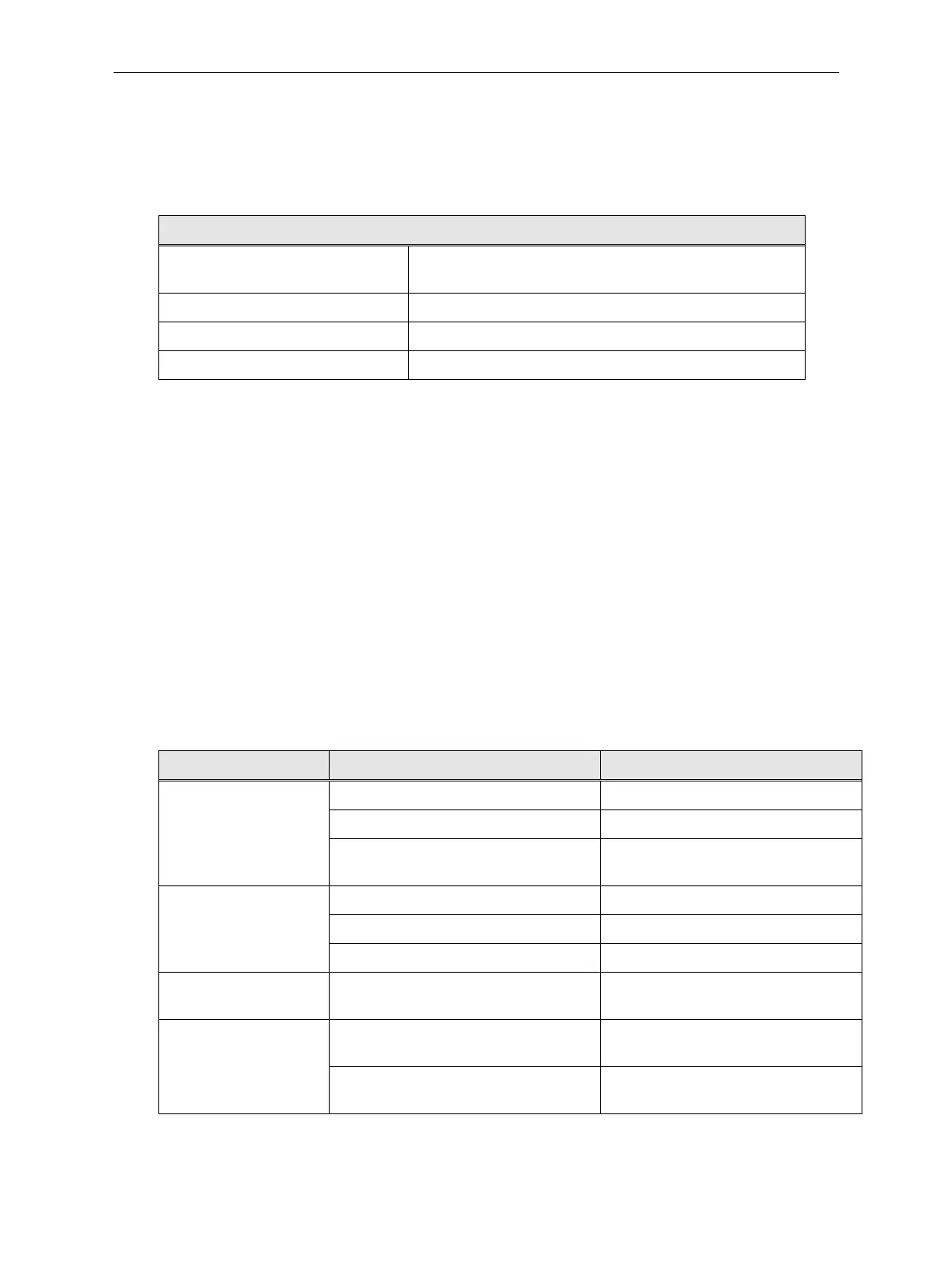

21. Maintenance Schedule

Table 8: Maintenance Schedule

Maintenance Schedule

Every 50,000 to 100,000

depending on coin type.

Using a mild detergent on a damp cloth.

No spray solvents should be used.

Every 500,000 coins. Replace ejector fingers and spring

Every 1,000,000 coins. Replace adjuster plate

Expected product lifetime: 3 million coins with routine maintenance

21.1 Clearing a coin jam:

¾ Remove all coins from bowl.

¾ Remove motor assembly from base as described.

¾ Clear the jammed coin by either:

i. Rotating the disk manually, first anti-clockwise then clockwise to free the coin

OR

ii. Push the coin back in using another coin.

¾ Remove any debris from the disk bed assembly.

¾ Clean the exit window opto with a clean dry cloth.

¾ Re-assemble, as described.

¾ Refill and test the hopper.

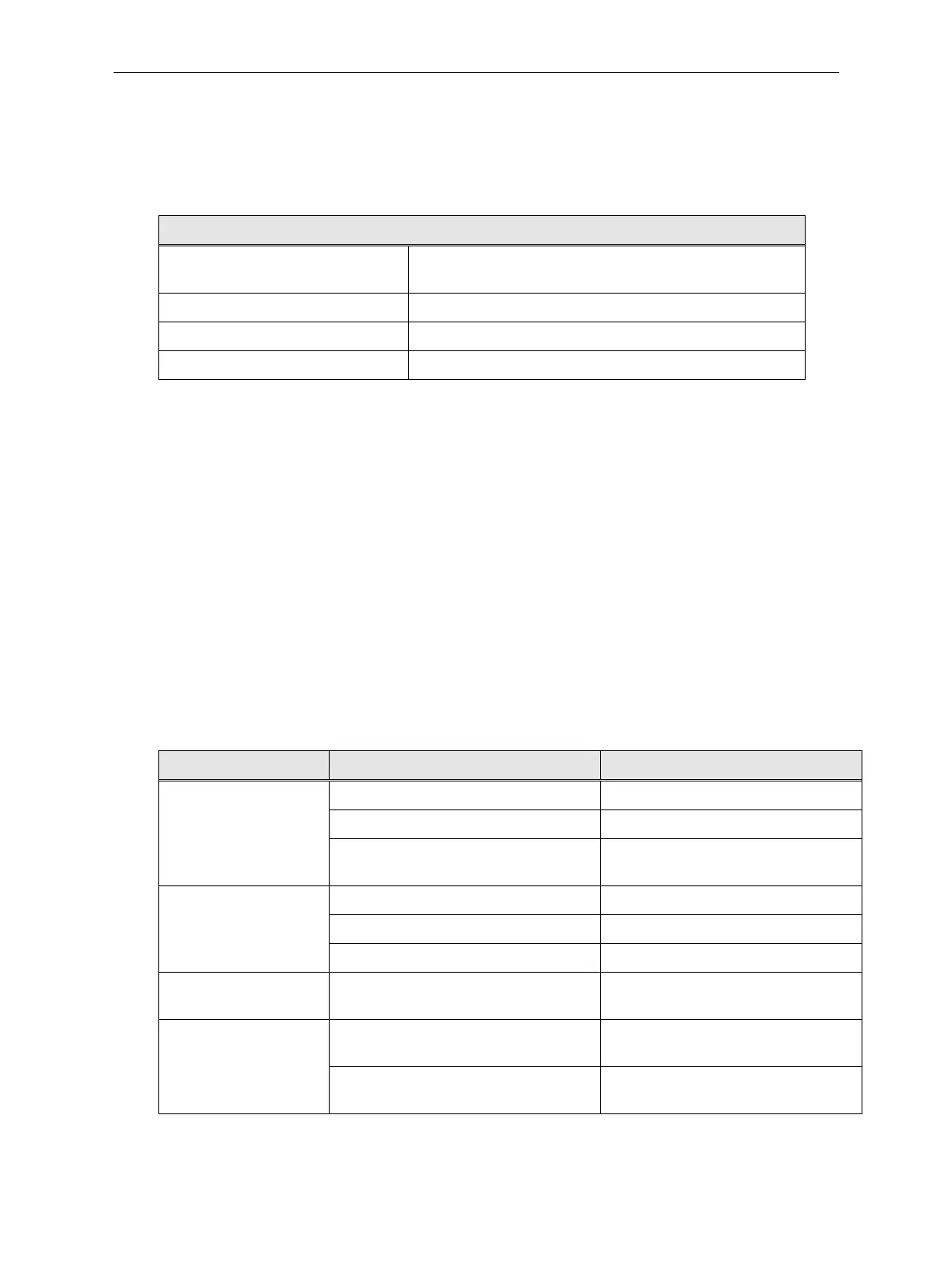

22. Fault Finding and Repair

Table 9: Fault Finding and Repair.

Problem: Check: Cure:

Ensure coin exit is clear. Remove blockage from coin exit.

Ensure correct coins in hopper. Fill hopper with correct coins.

Coins fail to unjam:

Ensure no badly bent coins in

hopper.

Remove bent coin/s.

Supply fuse. Replace fuse.

Protection device tripped. Wait 30 seconds with supply OFF.Motor fails to run:

Hopper has detected an opto fault. Check EEPROM flags.

Over payout of coins: Check opto area/coin exit area for

dirt.

Clean opto/coin exit area.

Check opto area/coin exit area for

dirt.

Clean opto/coin exit area.

Under Payout Of

Coins:

Ensure hopper contains sufficient

coins.

Refill hopper.

Loading...

Loading...