3

Description of the stove

The pellet stove is a heat generator capable of heating air

through the combustion of wooden pellets. The fuel is

loaded in an automated manner. The air present in the

environment is heated by the flame, produced by the

combustion of the pellets, and circulates in the room thanks to the

ventilator. This ventilator emits warm air directly into the room where the

stove is installed.

The safe use of the heater is guaranteed by the fact that on all Moretti

Design products, CE certified systems are installed and they control all

functions and parameters. The advanced software allows for the user a

more simple and immediate comprehension of the heaters functions.

The presence of a thermostat on all Moretti Design products allows the

user to program the on/off switching function of the stove. The large

pellet tank allows for a long period fuel loading procedure, avoiding this

way that the user has to refill the tank too often. The large ash drawer

allows the user to empty it just once a week when it is filled with ash (the

frequency of the operation may vary depending on how long the stove is

used and the quality of the pellets).

INSTALLATION

The stove must be placed on a floor with an adequate load

capacity. If the building does not meet this requirement,

appropriate measures (e.g. load distribution plate) must be taken.

The installation of the stove must ensure an easy access for

cleaning the heater, the flue and the chimney.

The presence of extraction fans in the same room or environment

where the appliance is installed in, can cause problems and should

therefore be avoided.

It is prohibited to install the stove in a small rooms or bedrooms. It

is forbidden to install the stove in rooms exposed to a high risk of

fire, in rooms with an explosive atmosphere or where other heat

generators are already present whose simultaneous presence is

not compatible according to standard regulations.

All local regulations and European standards must be met when the

stove is installed.

Supply conditions and unpacking

The stove is delivered packed together with its aesthetic components. To

unpack the stove, cut the straps and remove the box. Use the proper

equipment for lifting the appliance from the wooden pallet.

Assembling

For the installation of the stove, contact an authorized technician (the

penalty otherwise would be the void of the warranty).

Combustion air

A poor combustion can be caused by poor air circulation in the room and

this often occurs in modern homes that have sealed doors and windows.

The situation also becomes problematic when, on the contrary, there are

air currents inside the room (generated for example by fans). To avoid

this type of disadvantage, it is recommended to install a permanent

ventilation grid in a window or near the stove.

If there is no possibility of connecting the air intake directly to the outside

(see next paragraph), it is imperative to drill a hole on the wall for the

combustion air inlet for both health and safety reasons. It is

recommended the installation of an air grid over the opening and it must

be kept clean.

Combustion air for a hermetic installation

The air required for the combustion must be drawn

directly from the outside through a tube with a 60mm

diameter. The tube must not exceed 5m in length and

must not have more than 4 curves with a 90° angle. It is

recommended the installation of an air grid over the opening and it must

be kept clean (see the following example).

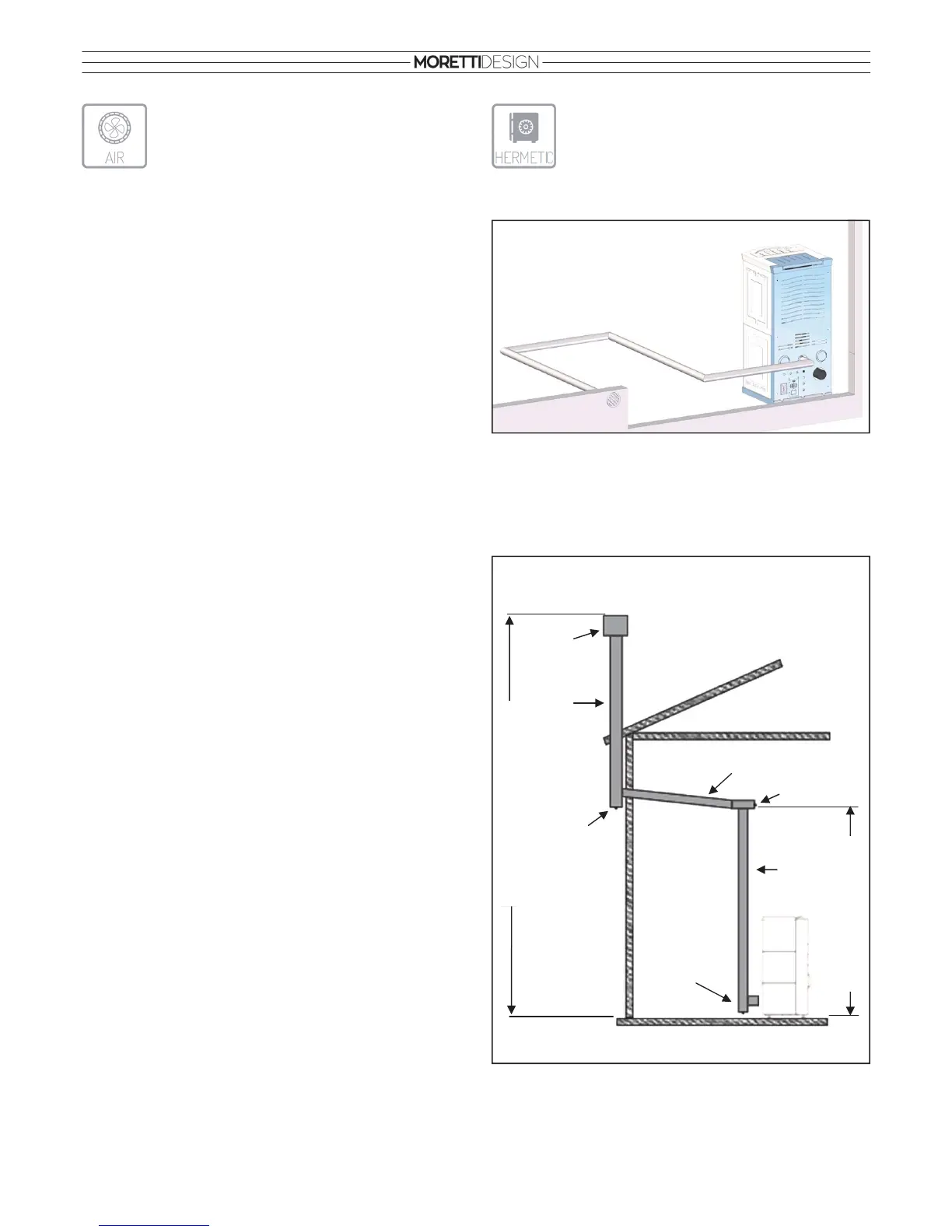

Fume exhaust

To extract the exhaust fumes, a flue must be installed in compliance with

standard regulations. The stove was not designed to share the flue with

other appliances.

Installation examples

EXAMPLE

DIMENSIONAL LIMITS

PROTECTION

CAP

INSULATED

CHIMNEY

FLUE

INSULATED “T” WITH

INSPECTION CAP

MAXIMUM LENGTH OF HORIZONTAL

STRETCH 3 METERS

MINIMUM SLOPE 5%

“T” WITH

INSPECTION

CAP

CHIMNEY

FLUE

“T” WITH

INSPECTION CAP

MINIMUM TOTAL HEIGHT 4 METERS

MINIMUM HEIGHT 1,5 METERS

Loading...

Loading...