Page43SYSTEM

Perforating

*Perforatorstripper177-05-01

Allofthebladesandanvilsaresuppliedwithfixings.

StandardPartNumber

*Itisrecommendedthatformultipleperforations,aseparateperforatorstripperisusedfor

everyperforatingbladesetfittedinthecreasingunit.

1.Turnthemainssupplytothemachine‘off’.

2.Opentheperforatorassemblytogetaccesstothedrivewheelsandhubs.

3.Locateandremovetheblades/anvilsfromthedespatchkitsuppliedwiththe

machine.

4.Usingthe2mmallenkey(supplied),loosenthedrivewheelthatistoaccommodate

theblades.

5.Slidethedrivewheelawayfromanyobstructingdrivewheelsorhubsinorderto

mounttheblades.

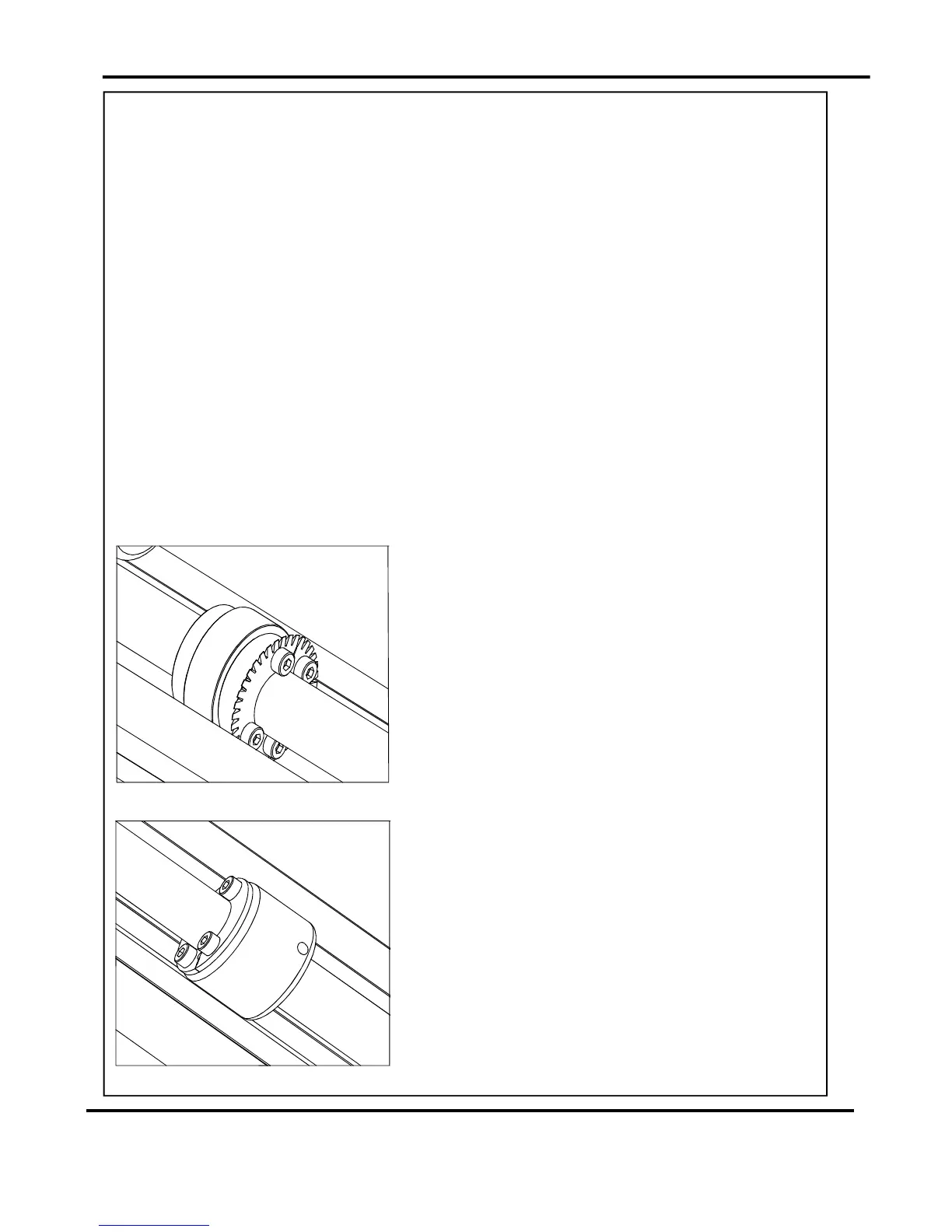

6.Usingthe2.5mmallenkey(supplied),takeone

halfofthematchingpairofbladesandmounton

tothedrivewheel.Donotsecuretheblade.

7.Mounttheotherhalfofthebladetothedrive

wheelasshown(FIG37.1).Securethebladesto

thewheelensuringnottoovertightengrubscrew.

8.Markonasinglesheetthedesiredperforating

position.Feedthesheetthroughthemachine

manuallyuntilthemarkcanbeseen.Usethis

marktoassistinfixingthepositionofthe

perforatingdrivewheeltotherollerdriveshaft.

9.Usingthe2mmallenkey,loosenthedrivehub

nearesttheperforatingdrive.Slidethedrivehub

awayfromanyobstructingdrivewheelsorhubs

inordertomounttheanvils.

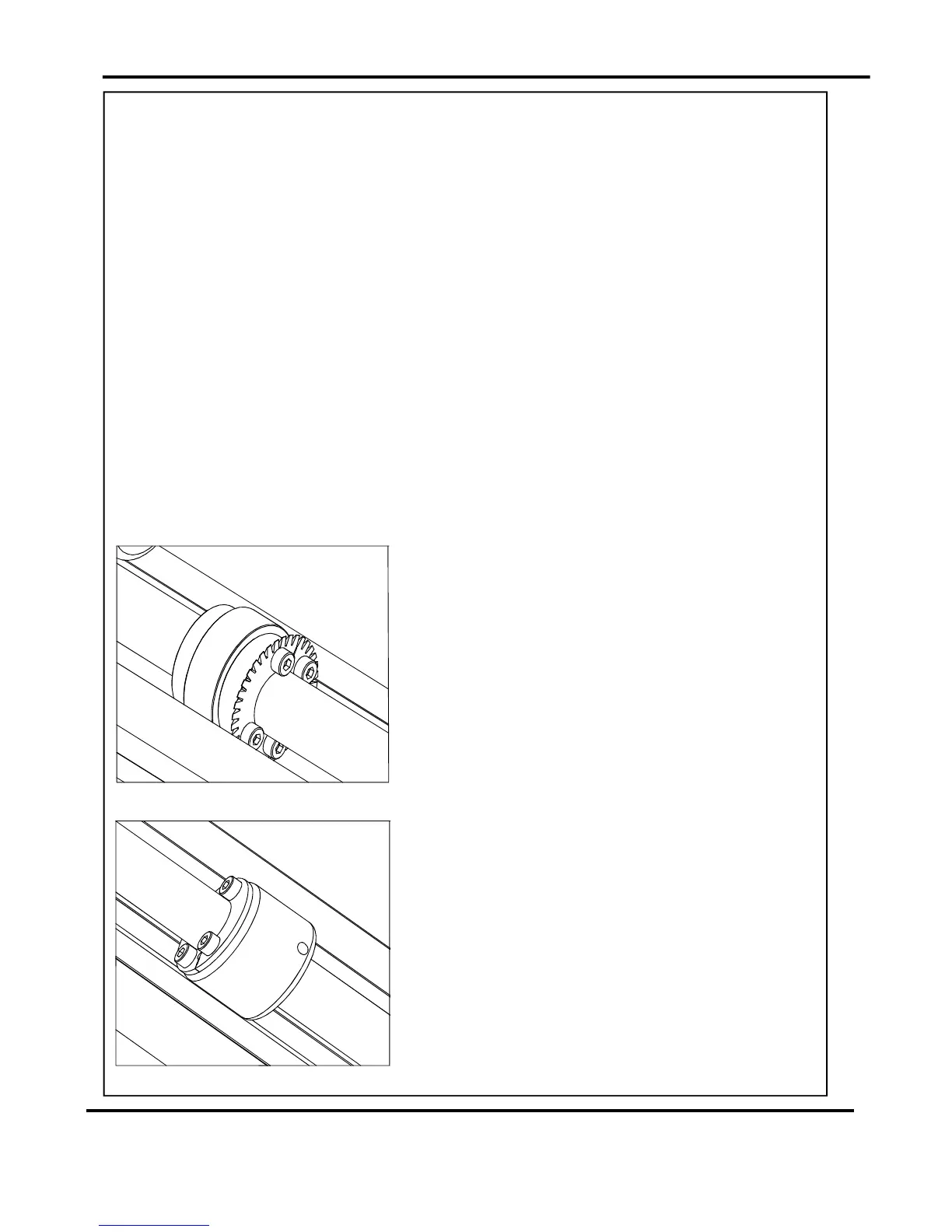

10.Usingthe2.5mmallenkey,takeonehalfofthe

matchingpairofanvilsandmounttothedrive

hub.Donotsecuretheanvil.

11.Mounttheotherhalfoftheanviltothedrivehub

asshown(FIG37.2).Securetheanvilstothedrive

hubensuringnottoovertightenthegrubscrews.

Settingthemachine

FIG37.1

FIG37.2

DigiFoldPro

Loading...

Loading...