UT1811 - 1010 - UK01

Page 27/32

ADJUSTABLE MULTISPINDLE HEADS

10 Maintenance

10 MAINTENANCE

10-1 Personnel in charge

OPERATOR: person trained for the normal use of the tool machine and authorised to

perform any adjustments or simple maintenance jobs.

TECHNICIAN: qualified and authorised person who performs complex maintenance and

repair jobs.

10-2 Scheduled maintenance

DANGER

All maintenance jobs must be performed when the machine is inactive and in safe

conditions for the operator. These operations must be performed by sufficiently

trained and skilled mechanical technicians.

Personnel required: Operator

• On a periodic basis:

Visually check that there are no leaks of lubricant from the head. In case leaks are found

contact the MPA engineering department.

Personnel required: Operator

• Every 1000 hours of use:

Every 1000 hours of use, or judging by experience, re-lubricate the head using the

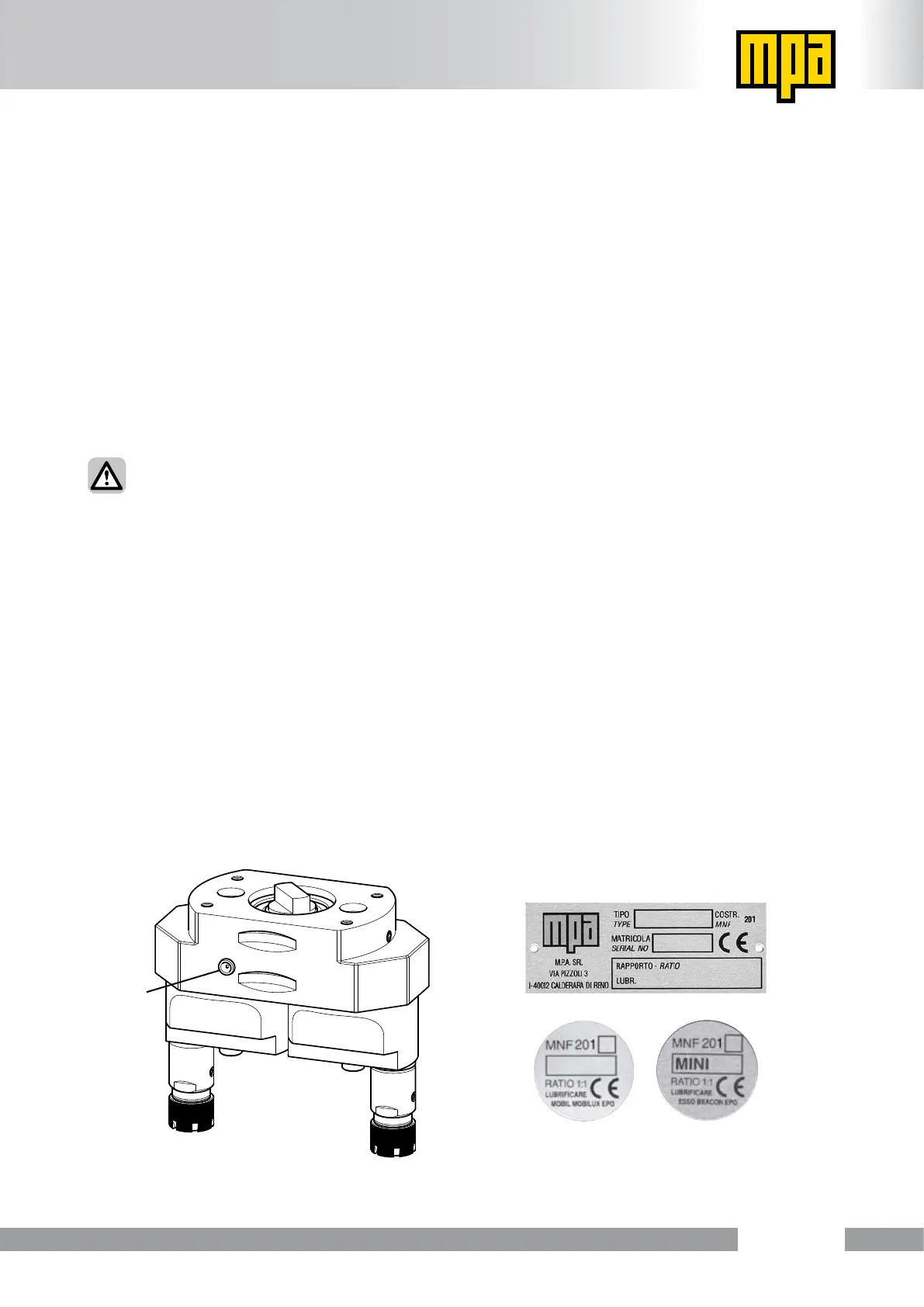

dedicated greasing valve 1 (Fig. 11) and/or feeding hole. The position of hole 1 may vary

depending on the purchased head model.

Fig. 11

1

Loading...

Loading...