CARBURETOR ADJUSTMENT

WARNING: If any adjustments are

made to the engine while the engine

is running (e.g. carburetor), keep

clear of all moving parts. Be careful

of heated surfaces and mufflers.

Minor carburetor adjustment may be required

to compensate for differences in fuel, tempera

-

ture, altitude and load.

Refer to the separate engine manual packed

with your unit for carburetor adjustment infor

-

mation.

NOTE: Failure to comply with suggested

maintenance and lubrication specifica

-

tion will void warranty.

LUBRICATION

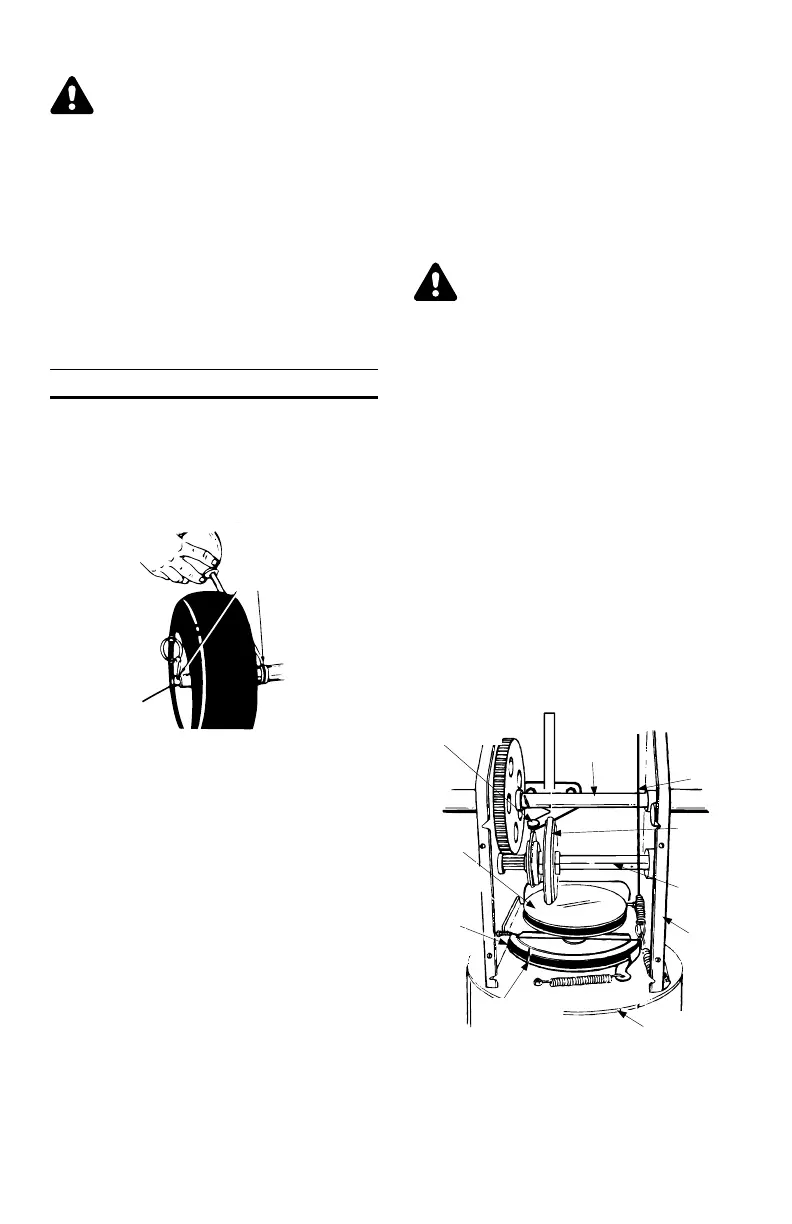

WHEELS

Oil or spray lubricant into bearings at wheels at

least once a season. Remove wheels, clean

and coat axles with a multi-purpose automotive

grease. See figure 17.

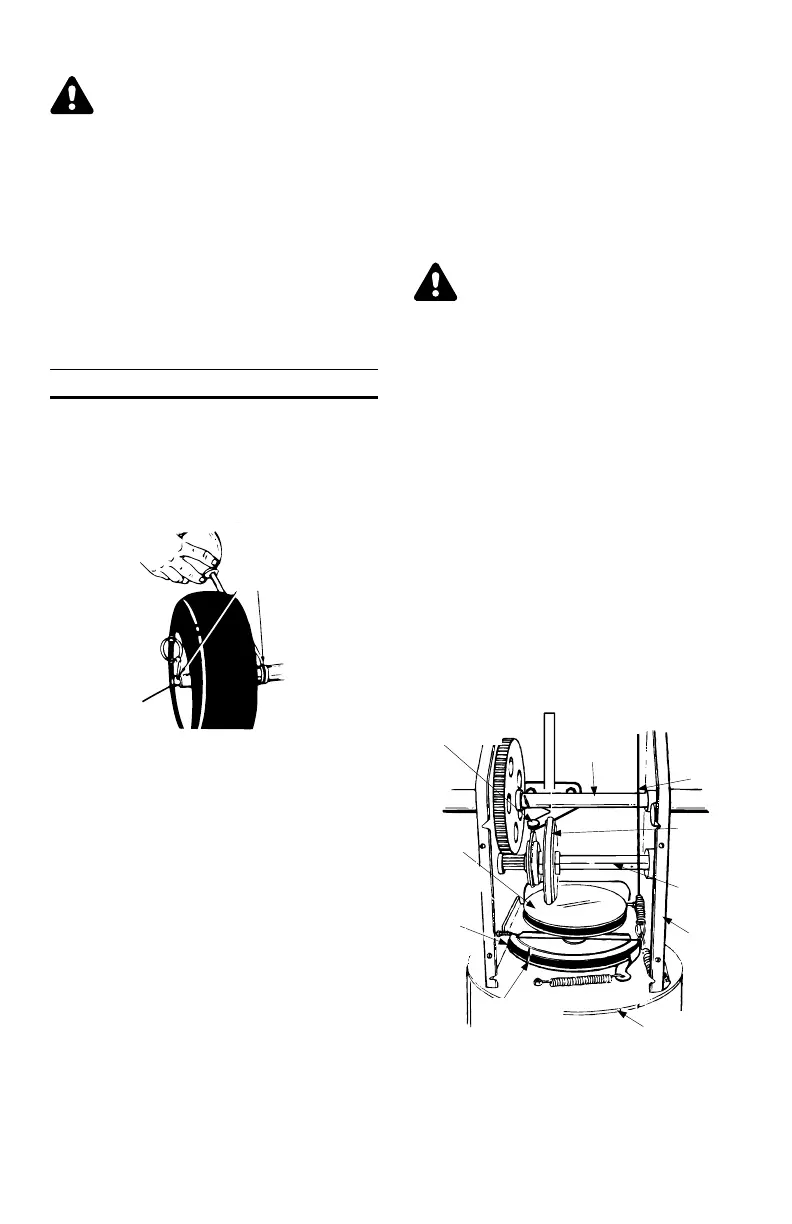

DRIVE AND SHIFTING MECHANISM

Remove rear cover. Oil any chains, sprockets,

gears, bearings, shafts, and shifting mechanism

at least once a season. Use engine oil or a

spray lubricant. Avoid getting oil on rubber fric

-

tion wheel and aluminum drive plate.

GEAR BOX

The worm gear box has been filled with grease

at the factory. If disassembled for any reason,

lubricate with 1.5 ounces of Shell Alvania

grease EPR00, part number 737-0168. Before

reassembling remove old sealant and apply

“Loctite 5699" or equivalent.

CAUTION: Do not overfill the gear box, damage

to the seals could result. Be sure the vent plug

is free of grease in order to relieve pressure.

CHUTE CRANK WORM

The worm gear on the chute direction crank

should be greased with multi-purpose automo

-

tive grease.

AUGER SHAFT

Remove auger bolts on auger shaft. Oil or

spray lubricant inside shaft. See figure 19.

ENGINE

Refer to engine manual for engine lubrication

instructions.

WARNING: When following instruc

-

tions in separate engine manual for

draining oil, be sure to protect frame

to avoid oil dripping onto transmis

-

sion parts.

Gear Shaft

Lubricate the gear (hex) shaft with a light

weight cold weather lubricant at lease once a

season or after every 25 hours of operation.

IMPORTANT: Keep all grease and oil off of the

rubber friction wheel and aluminum drive plate.

If for any reason your transmission was disas

-

sembled and the drive cable disconnected,

make sure when reassembling to route the ca-

ble correctly before reconnecting to support

bracket. See figure 18.

Models with 13” and 15” wheels: Pass the

drive cable between the drive shaft and the

gear shaft.

Models with 16” wheels: Pass the drive ca-

ble under the drive shaft and the gear shaft.

13

FIGURE 17

Oil Bearings

Or Spray Lubricant

Axle

FIGURE 18

Friction

Wheel

Disc

Auger

Belt

Friction

Wheel

Auger

Pulley

Shift

mechanism

Drive

Shaft

Drive

cable

Auger

Housing

Gear

Shaft

Frame

Loading...

Loading...