61/ 65/70/75 Series Horizontal Shaft Engines

14

61/65/70 series engines

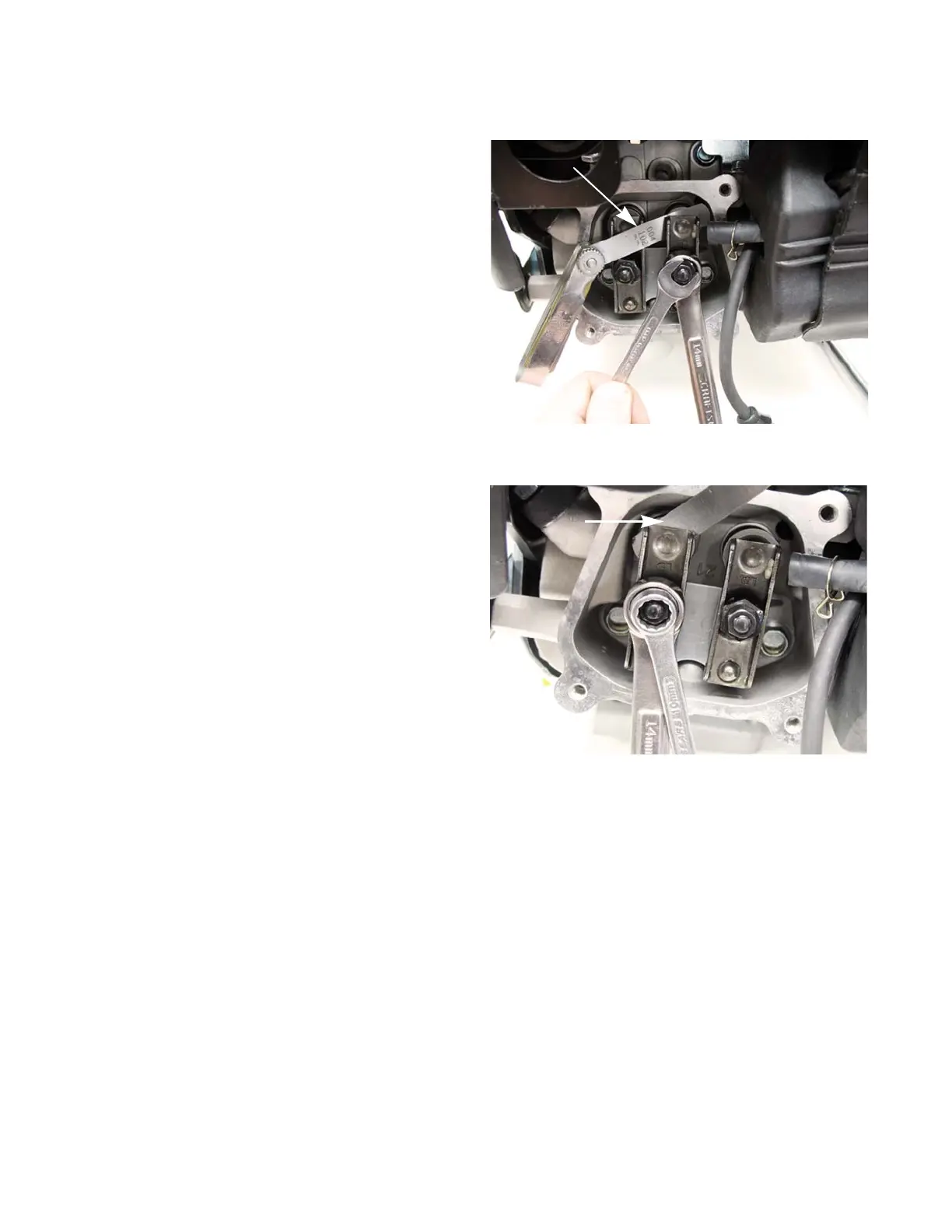

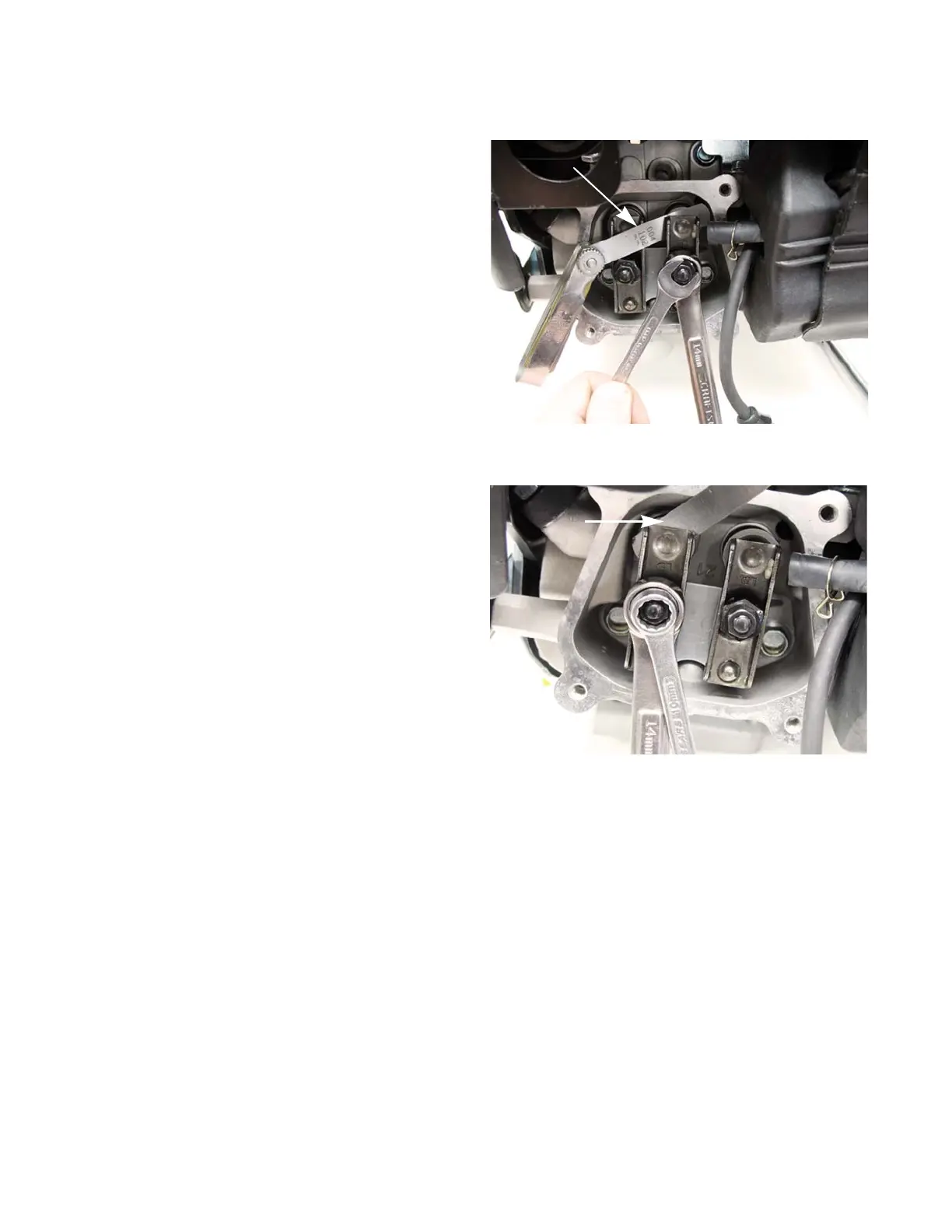

6. Check valve lash between each valve stem and

rocker arm using a feeler gauge.

6a. Intake valve lash should be 0.004” - 0.006”

(0.10 - 0.15 mm). See Figure 1.14.

6b. Exhaust valve lash should be 0.006” - 0.008”

(0.15 - 0.20 mm). See Figure 1.15.

6c. Use a 10mm wrench to loosen the jam nut,

and a 14mm wrench to adjust the rocker arm

fulcrum nut.

• Tighten the rocker arm fulcrum nut to close-up

the clearance between the end of the valve

stem and the contact point on the rocker arm.

• Loosen the rocker arm fulcrum nut to open-up

the clearance between the end of the valve

stem and the contact point on the rocker arm.

6d. Hold the fulcrum nut with a 14mm wrench,

tighten the jam nut to a torque of 80 - 106 in-

lb. (9 - 12 Nm) using a 10mm wrench.

6e. Double-check the clearance after tightening the jam nut, to confirm that it did not shift. Re-adjust if nec-

essary.

Figure 1.14

Setting intake valve lash

0.004” feeler

gauge

0.006” feeler

gauge

Figure 1.15

Loading...

Loading...