Introduction

15

75 series engines

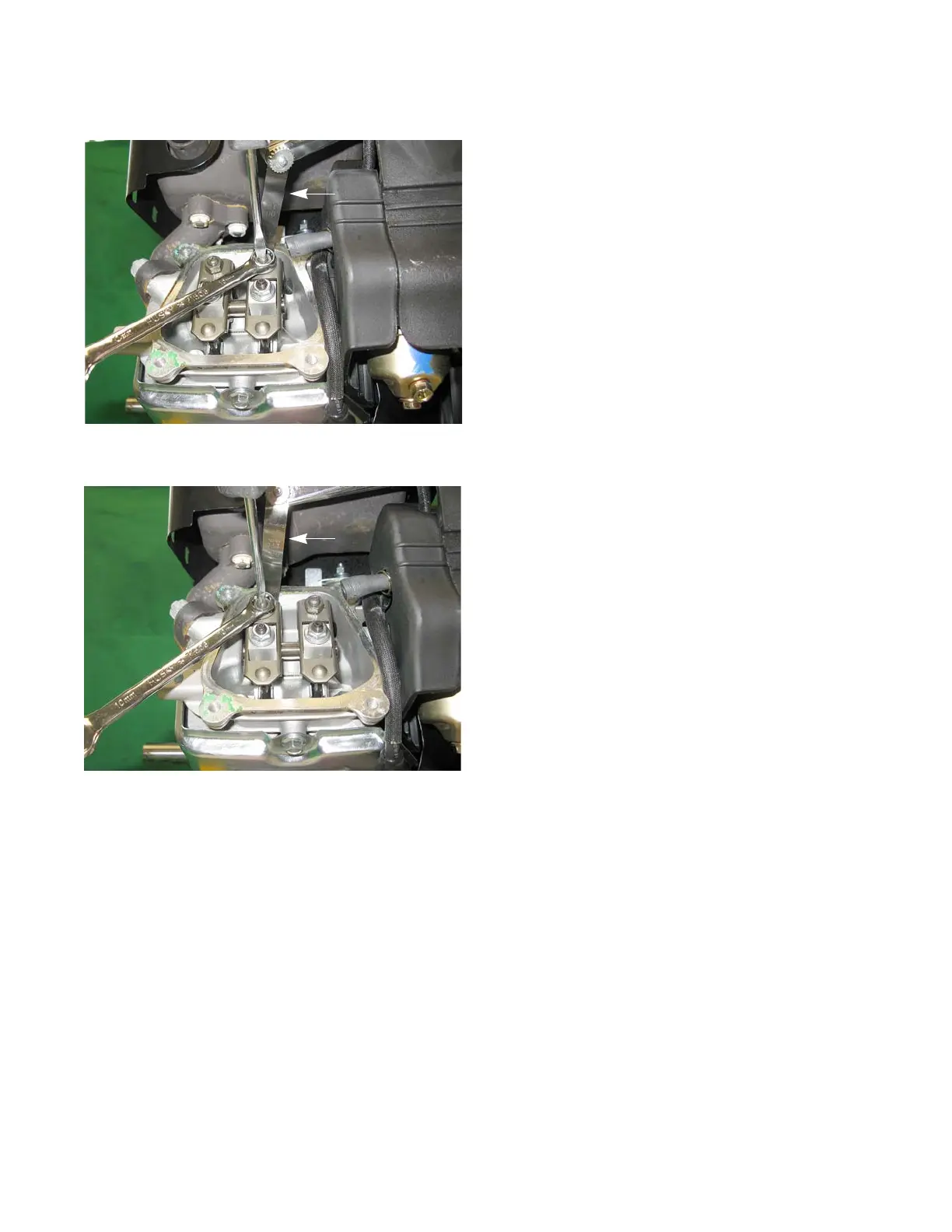

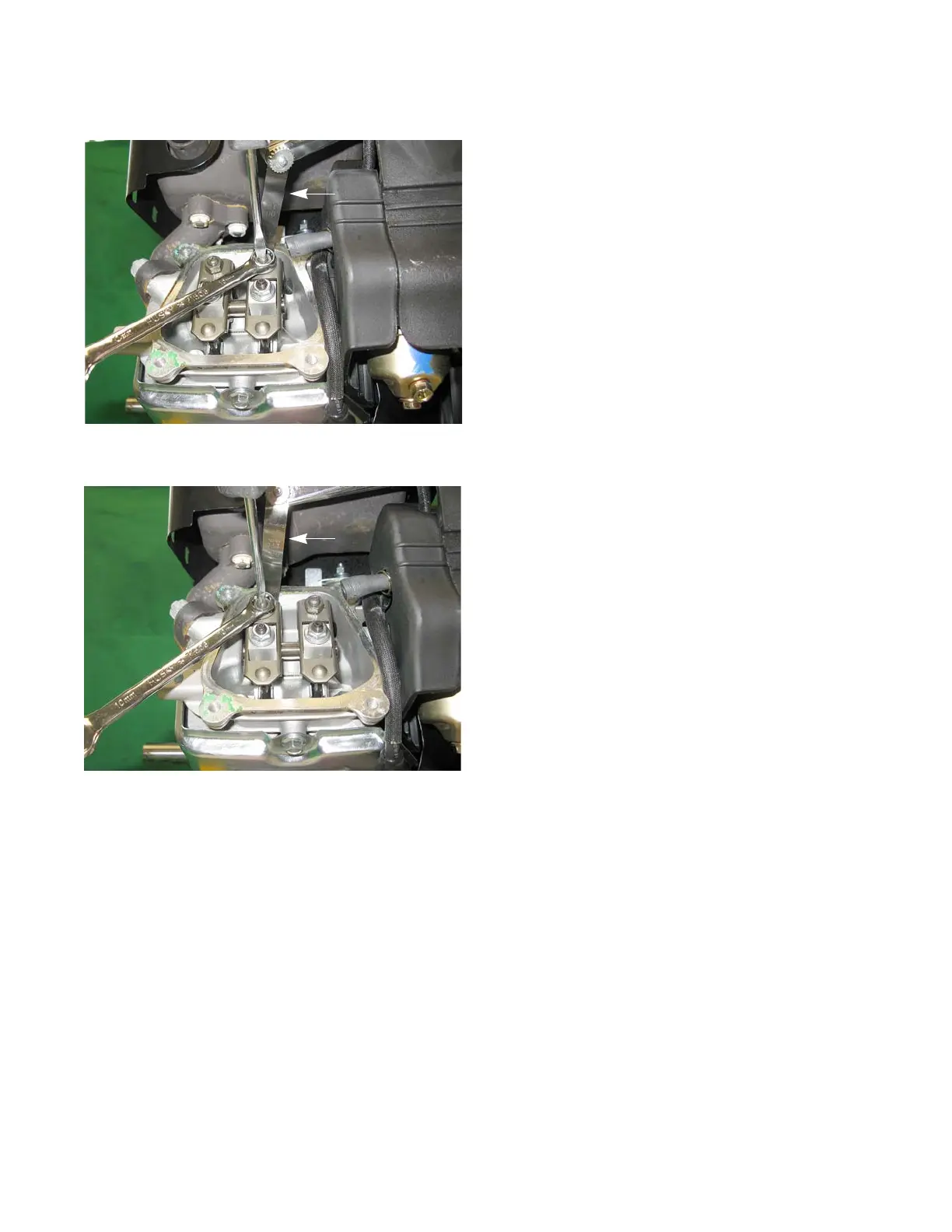

6. Check valve lash between each valve stem and

rocker arm using a feeler gauge.

6a. Intake valve lash should be 0.004” - 0.006”

(0.10 - 0.15 mm). See Figure 1.16.

6b. Exhaust valve lash should be 0.006” - 0.008”

(0.15 - 0.20 mm). See Figure 1.17.

6c. Use a 10mm wrench to loosen the jam nut.

Adjust the jack screw using a small flat headed

screw driver.

• Tighten the jack screw to close-up the clearance

between the end of the valve stem and the contact

point on the rocker arm.

• Loosen the jack screw to open-up the clearance

between the end of the valve stem and the contact

point on the rocker arm.

7. Rotate the engine through several compression cycles:

• Observe the movement of the valve gear.

• Return the piston to TDC compression stroke and re-check the valve lash to confirm consistent movement

of the valve gear, including the slight bump to the exhaust valve from the automatic compression release.

8. Clean-up any oil around the valve cover opening, clean the valve cover, replace the valve cover gasket if nec-

essary.

9. Install the valve cover, tightening the valve cover screws to a torque of 62 - 80 in-lbs (7 - 9 Nm).

IMPORTANT: Over tightening the valve cover will cause it to leak.

10. Install the spark plug.

11. Test run the engine before returning it to service.

Loading...

Loading...