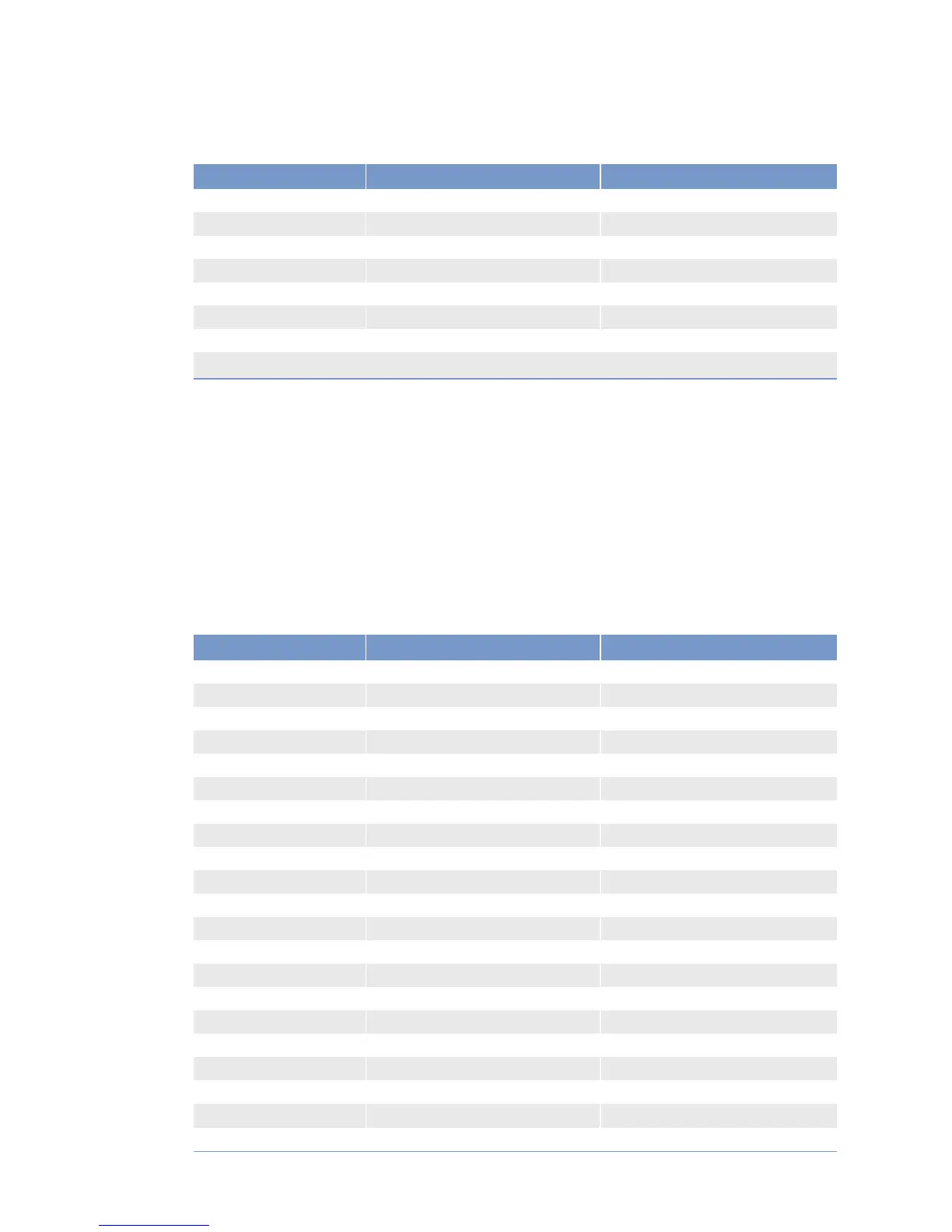

Tightening torque for self-locking hex nuts

Thread

M

A

(Nm)

Lubricant

M6 7,5 +1 –

M8 17 +2 –

M10 35 +4 –

M12 59 +6 –

M14 100 +10 –

M16 140 +14 –

M20 290 +29 –

M

A

= tightening torques

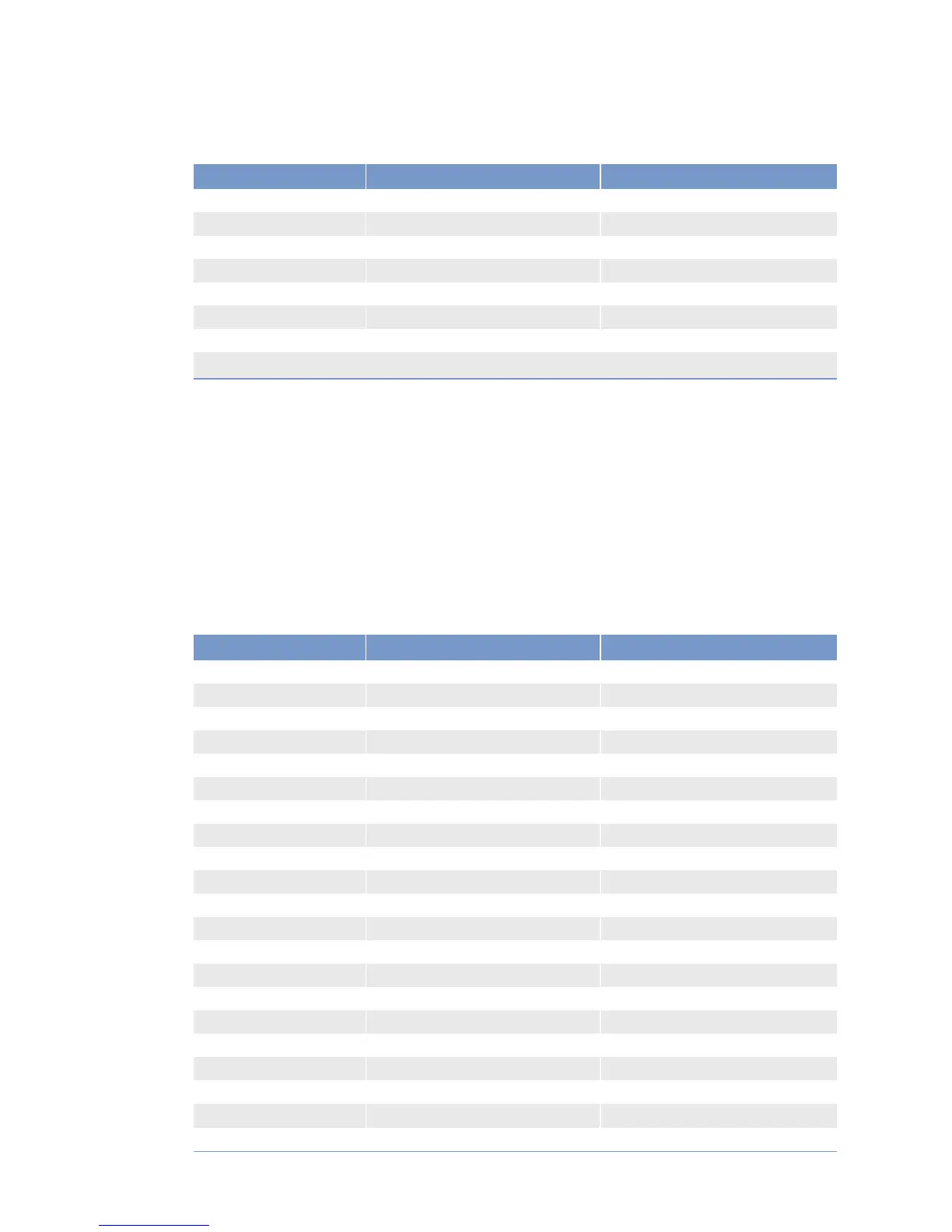

Tightening torques for stress bolt connections to MTN 5007 standard

This standard applies to stress pin bolts and stress bolts which are subjected to static and dynamic load of

strength class 10.9 as well as to the associated nuts.

Shank and junction dimensions to MMN 209 standard and material and manufacture to MMN 389 standard

(bare metal or phosphatized).

The values in the table are based on a friction coefficient µtot = 0.125.

Threads and mating faces of screws and nuts must be coated with engine oil prior to assembly.

An assembly tolerance of +10% of the figures in the table is permitted due to unavoidable deviations during

the tightening process.

The figures in the table are for hand-tightening using a torque wrench.

Thread

Not torsion-protected M

A

(Nm) Torsion-protected M

A

(Nm)

M6 9 12

M8 21 28

M8 x 1 24 30

M10 42 55

M10 x 1.25 46 60

M12 75 93

M12 x 1.5 78 99

M14 120 150

M14 x 1.5 135 160

M16 180 225

M16 x 1.5 200 245

M18 250 315

M18 x 1.5 300 360

M20 350 450

M20 x 1.5 430 495

M22 500 620

M22 x 1.5 560 675

M24 640 790

M24 x 2 700 850

M27 900 1170

M27 x 2 1000 1230

18 | General Information | MS150119/01E 2016-02

TIM-ID: 0000002333 - 017

Loading...

Loading...