PAGE 24 — WTB-16PD TRACK-DRIVE POWER BUGGY • OPERATION MANUAL — REV. #0 (08/31/20)

BATTERY

This unit is of negative ground. DO NOT connect in reverse.

ALWAYS maintain battery fluid level between the specified

marks. Battery life will be shortened if the fluid levels are

not properly maintained. Add only distilled water when

replenishment is necessary. DO NOT overfill.

Check to see whether the battery cables are loose. Poor

contact may result in poor starting or malfunctions.

ALWAYS keep the terminals firmly tightened. Coat the

terminals with an approved battery terminal treatment

compound. Replace the battery with only the recommended

type battery. The battery type used in this power buggy is

BCI Group U1.

The battery is sufficiently charged if the specific gravity

of the battery fluid is 1.28 (at 68°F). If the specific gravity

should fall to 1.245 or lower, it indicates that the battery is

dead and needs to be recharged or replaced.

Before charging the battery with an external electric source,

be sure to disconnect the battery cables.

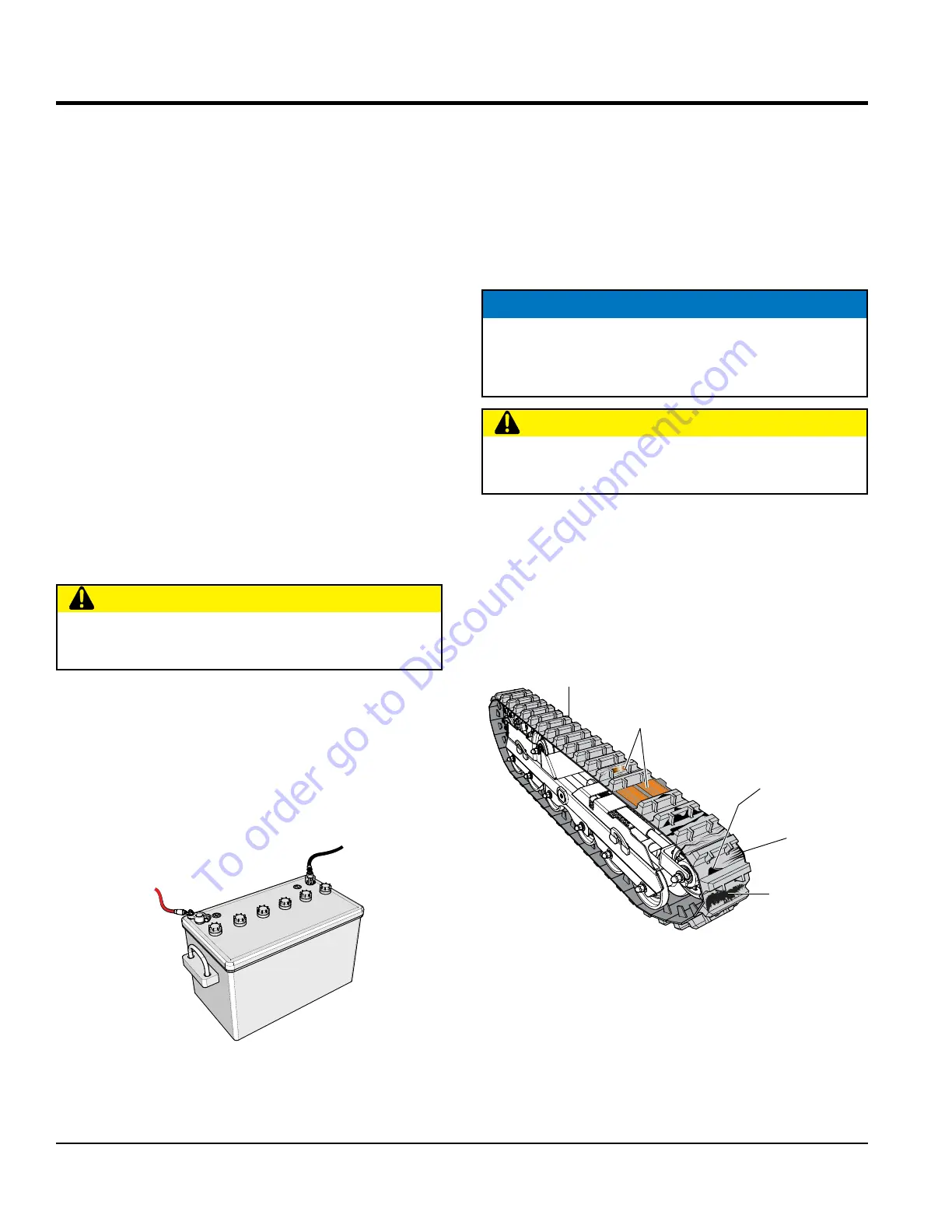

Battery Cable Installation

ALWAYS be sure the battery cables (Figure 9) are properly

connected to the battery terminals as shown below. The red

cable is connected to the positive terminal of the battery

and the black cable is connected to the negative terminal

of the battery.

Figure 9. Battery Connections

CAUTION

ALWAYS disconnect the negative terminal FIRST and

reconnect negative terminal LAST.

POSITIVE

NEGATIVE

INSPECTION

When connecting the battery do the following:

1. NEVER connect the battery cables to the battery

terminals when the ignition is in the ON (start) position.

2. Place a small amount of battery terminal treatment

compound around both battery terminals. This will

ensure a good connection and will help prevent

corrosion around the battery terminals.

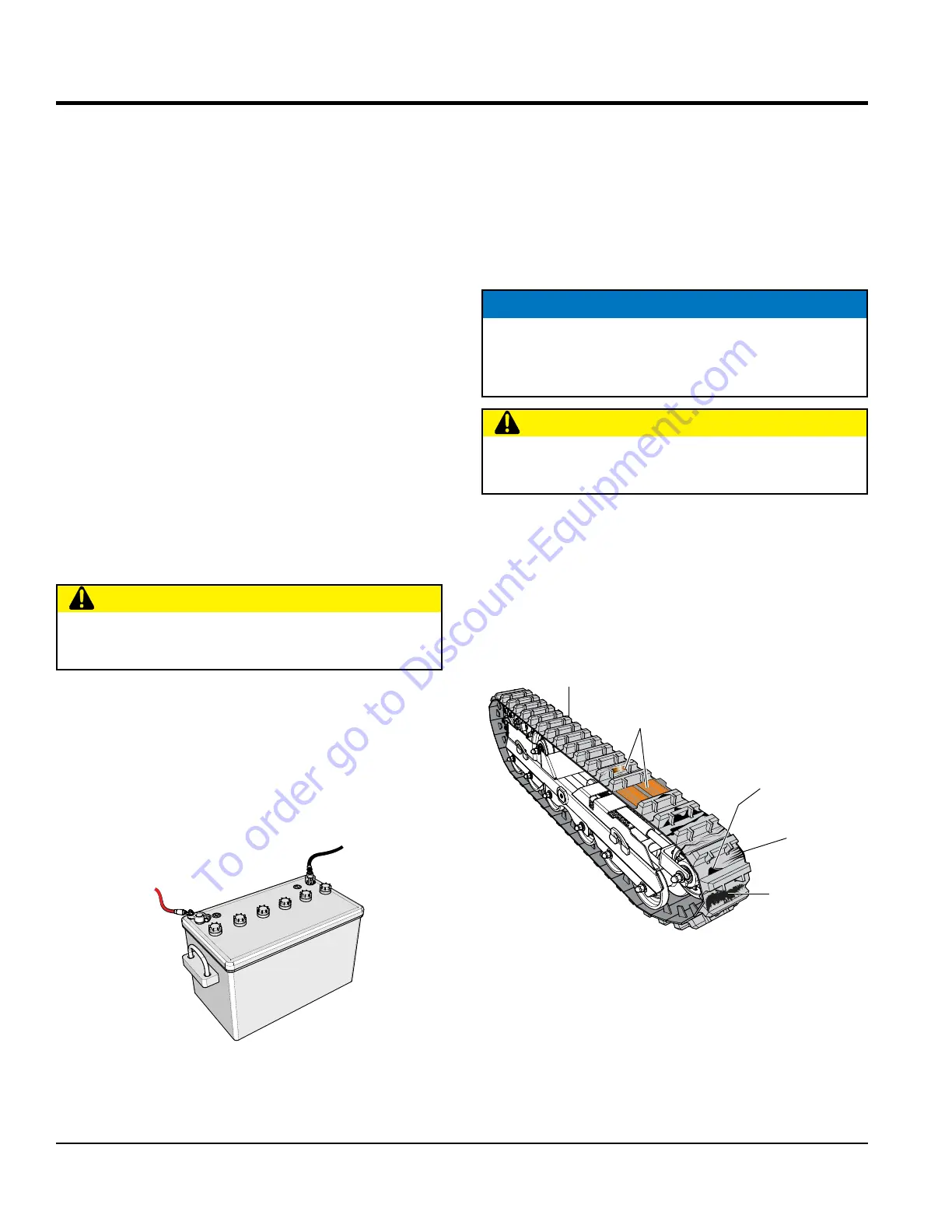

RUBBER TRACK CHECK

The rubber tracks installed on the track buggy are very

important for its effective operation.

1. ALWAYS check the rubber tracks (Figure 10) for cuts

and abrasions.

Figure 10. Rubber Track Inspection

2. DO NOT operate the track buggy if the rubber track is

deformed or damaged.

3. Check the tension of the rubber track every 50 hours.

Reference the Maintenance section in this manual on

how to check rubber track tension.

CAUTION

Inadequate battery connections may cause poor starting

of the power buggy and create other malfunctions.

NOTICE

If the battery cable is connected incorrectly, electrical

damage to the power buggy will occur. Pay close attention

to the polarity of the battery when connecting the battery.

MISSING

RUBBER

WORN

RUBBER

CRACKED

RUBBER

EXPOSED

STEEL CORD

RUBBER

TRACK

To order go to Discount-Equipment.com

Loading...

Loading...