MCS300

3.8Connectionofductsandhoses

3.8.1General

Followtheinstructionsbelowwhenattachingductsorexiblehosestotheunit'sairconnections.

■Ductlengthshouldbekeptasshortaspossibletominimisestaticpressureloss.

■Allductandhoseconnectionsmustbeairtightandvapourtighttoensurefullperformance.

■Toretainthecorrectairowforreactivationair,anairdampermustbeinstalled.Thisdamperistobe

installedinthewetairoutletducting,seeFigure3.2andFigure3.3.Foradjustmentofairow ,followthe

instructionsinsection4.5,Adjustingreactivationtemperature.

■Ductingforwetairshallbeinstalledatadownwardinclinetoenablecondensatetodrain.Thewet

airductingshouldbeprovidedwithsuitabledrainageatlowpointstopreventthecollectionof

condensationwater.Alternatively,condensationcanbeavoidedbyinsulatingtheductwithatleast

25mmofsuitableinsulatingmaterial.

■Covertheductopeningwithmeshtopreventbirdsandrodentsfromenteringtheunit.Positionthe

openingsothatrainandsnowcannotenterthelines.

■Thewetairductorhosemustbecorrosionresistantandabletowithstandtemperaturesupto70°C.

CA CA

CA

UTION! UTION!

UTION!

Ifthereisriskforfreezingtemperatures,thewetairductingmustbeinsulated.

3.8.2Installationexamples

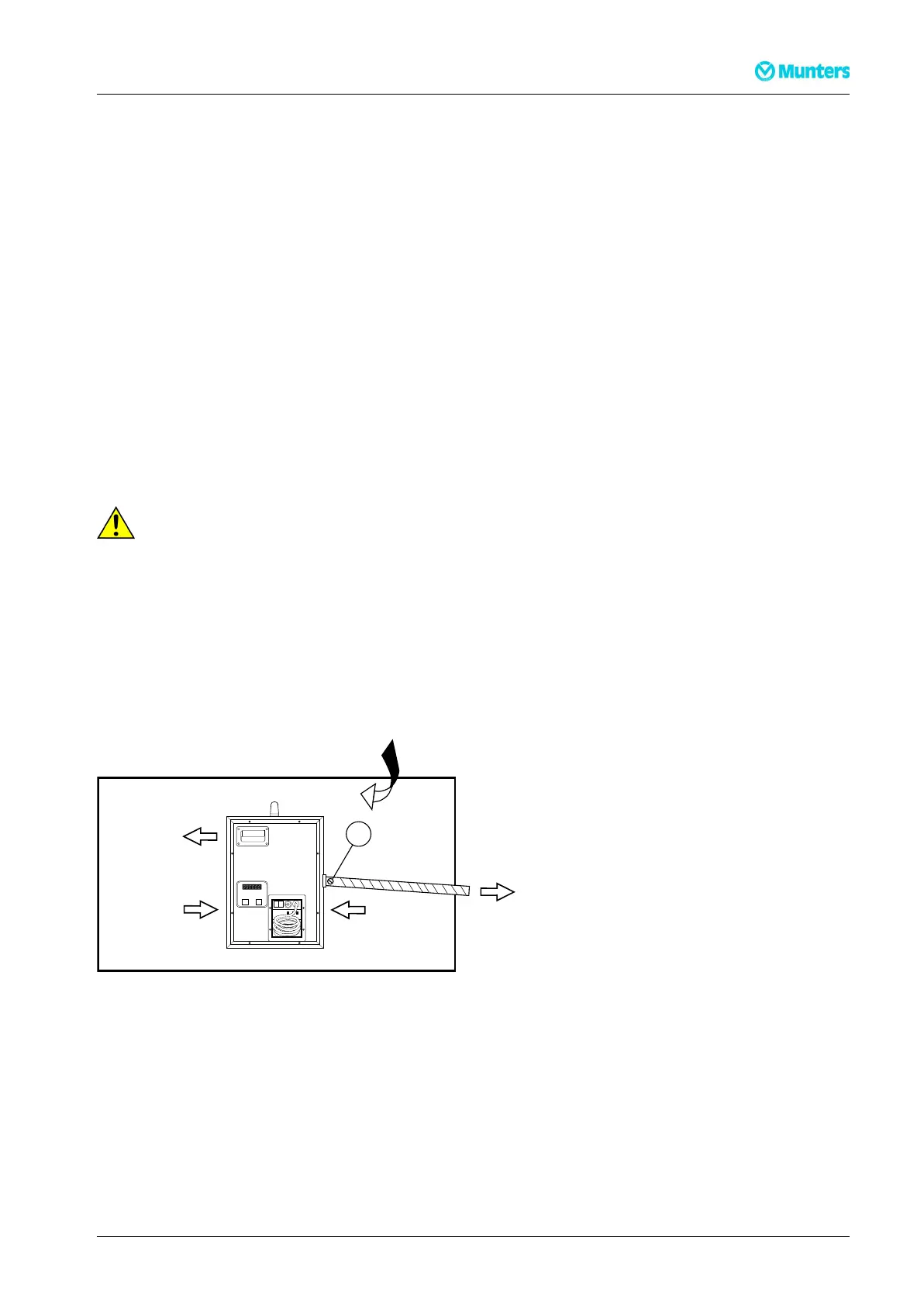

Closedairowsystem

Thedehumidierisplacedinthespacetobedehumidied.Thewetairistransportedoutdoorswithducting.

Noconnectionismadetothedryairoutlet,seeFigure3.2.Theadvantagewiththisinstallationmethodisa

simplersetup;ductingdoesnotneedtobeconnectedtothedryairoutlet.

Figure3.2Installationinaclosedairowsystem.

A.DryairD.Leakageair

B.ProcessairE.Wetair

C.Connectiontting

1)

F.Reactivationair

1)

Fittingwithdiameter80mm(forexample,LindabSafeNPUnippleoralternateLindabDamperDRU80).

190TEN-1027-F1404Installation8

Loading...

Loading...