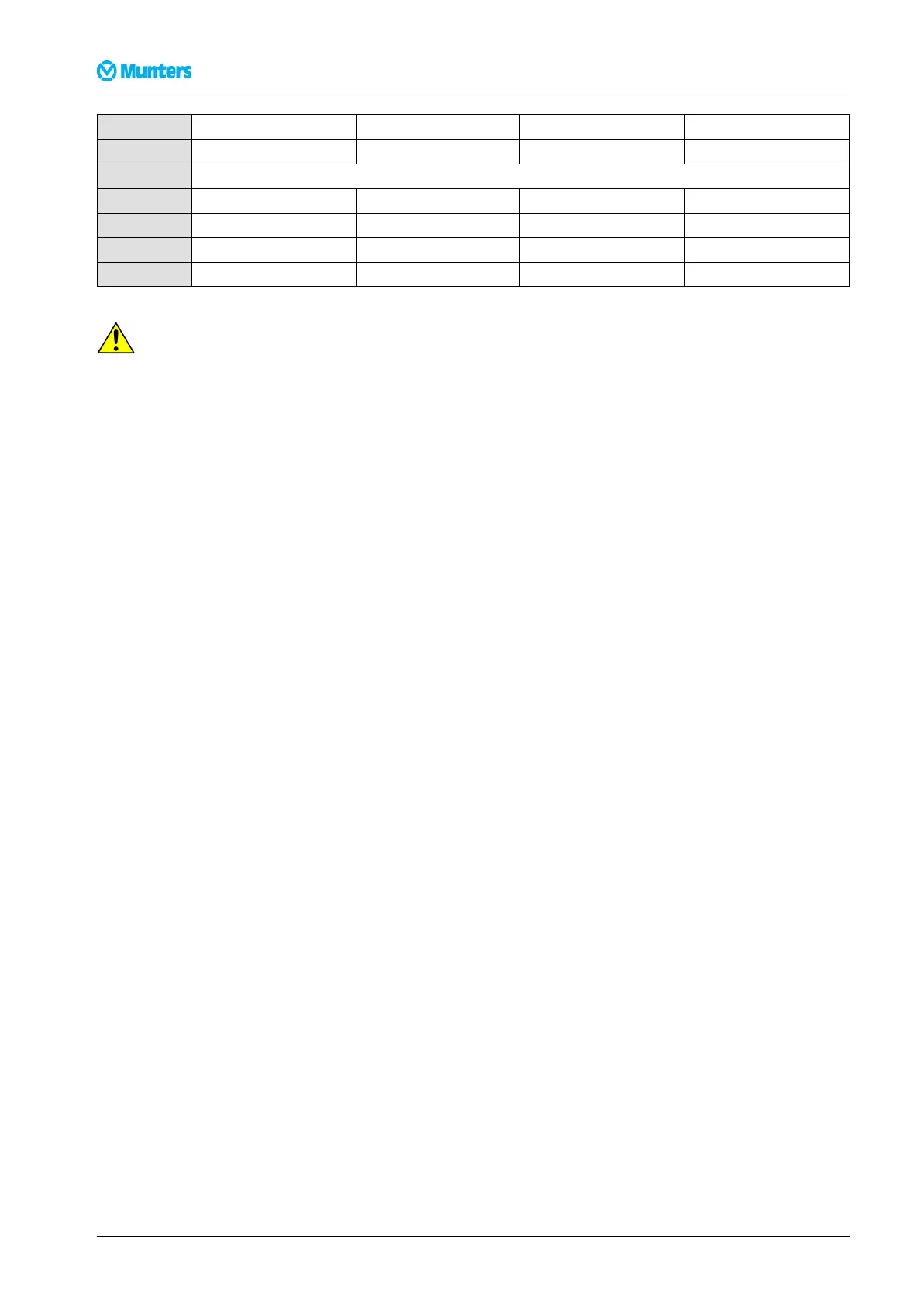

DehumidierML180-MLT350

Partnumber170-013477–001170-013477–002170-013477–003170-013477–004

A

Ø80Ø100Ø125Ø160

B

See9.1,Dimensionsandservicespace.

L(mm)

225225220140

ML180XX

ML270XX

MLT350XX

CA CA

CA

UTION! UTION!

UTION!

Thedehumidierhasbeendesignedtooperateatspecicprocessairowscorrespondingtothefansizes

installed.

■Theprocessairanddryairductsshouldbethesamediameter.Thesameappliestothereactivationair

andwetairducts.

■Thelengthofductworkmustbekeptasshortaspossibletominimisestaticairpressurelosses.

■Tomaintainperformance,allrigidprocessorreactivationairductworkjointsmustbeairandvapour

tight.

■Theprocessairductworkmustbeinsulatedtopreventcondensationdevelopingontheoutsideofthe

duct,wheneverthetemperatureoftheairwithintheductfallsbelowthedewpointtemperatureofthe

ambientairthroughwhichtheductworkisrouted.

■Theductsmustalwaysbeinsulatedwhenthereisariskoffreezing.

■Thewetairleavingthedehumidierwill,becauseofhighmoisturecontent,condenseontheinsideduct

walls.Byinsulatingtheducts,theamountofcondensateisreduced.

■Horizontalwetairductsmustbeinstalledwithaslightdecline(awayfromthedehumidier)todrain

awaypossiblecondensation.Suitablecondensationdrainsmustbeinstalledatlowpointsinthewet

airoutletduct,seeFigure4.6.

■Ensurethataccessforoperationandservicingisnotrestrictedwhendesigningandinstallingducting.

Formoreinformation,refertosection9.1,Dimensionsandservicespace.

■Toreducenoiseand/orvibrationbeingtransmittedalongrigidducts,goodquality,airtightexible

connectionscanbetted.

■Ductsmounteddirectlyontotheunitmustbeindependentlysupportedtominimisetheloadontheunit.

■Dampersforadjustingtheairowsmustbeinstalledinthesupplyairoutletandreactivationairinlet

ducts.Correctairowsareessentialfortheoperatingefciencyoftheunit.Forairowadjustment

instructions,seesection5.2,Airowcheckandadjustment.

■Thetotalpressuredropintheprocessandreactivationductworkmustnotexceedtheavailablepressure

ofthefansttedtothedehumidier.Fordetailsofminimumavailablestaticpressure,seesection

9.3,Technicaldata.

10Installation190TGB-1034-L1604

Loading...

Loading...