6.8 Maintenanceofsteamreactivationheater

Adjustment, maintenance and re pairs should only be carried out by qualified personnel who are awa re of the

hazards of operating and maintaining equipment operating with high voltages and high steam temperatures.

Before atte m p ting to carry out a ny ins p e ction or maintenance in the heater compartment, the reactivation

heater must be allowed to cool down.

The following must be carried out before the dehumidifier is re-started:

1. Examine all ductwork and duct insulation for cor rect connection and for general signs of damage and

leaks.

2. Examine the steam connections to ensure that all pipes are correctly installed and secured.

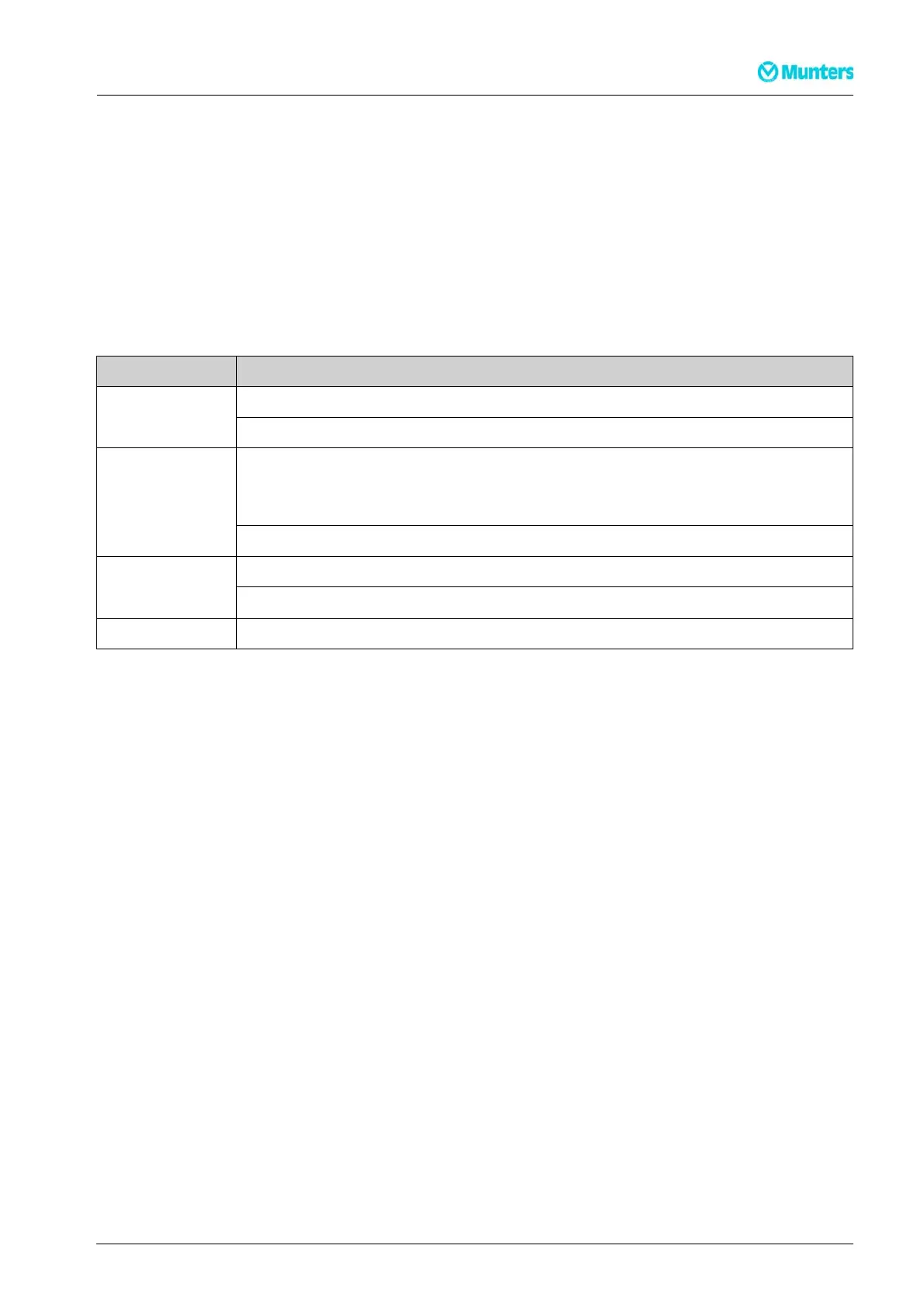

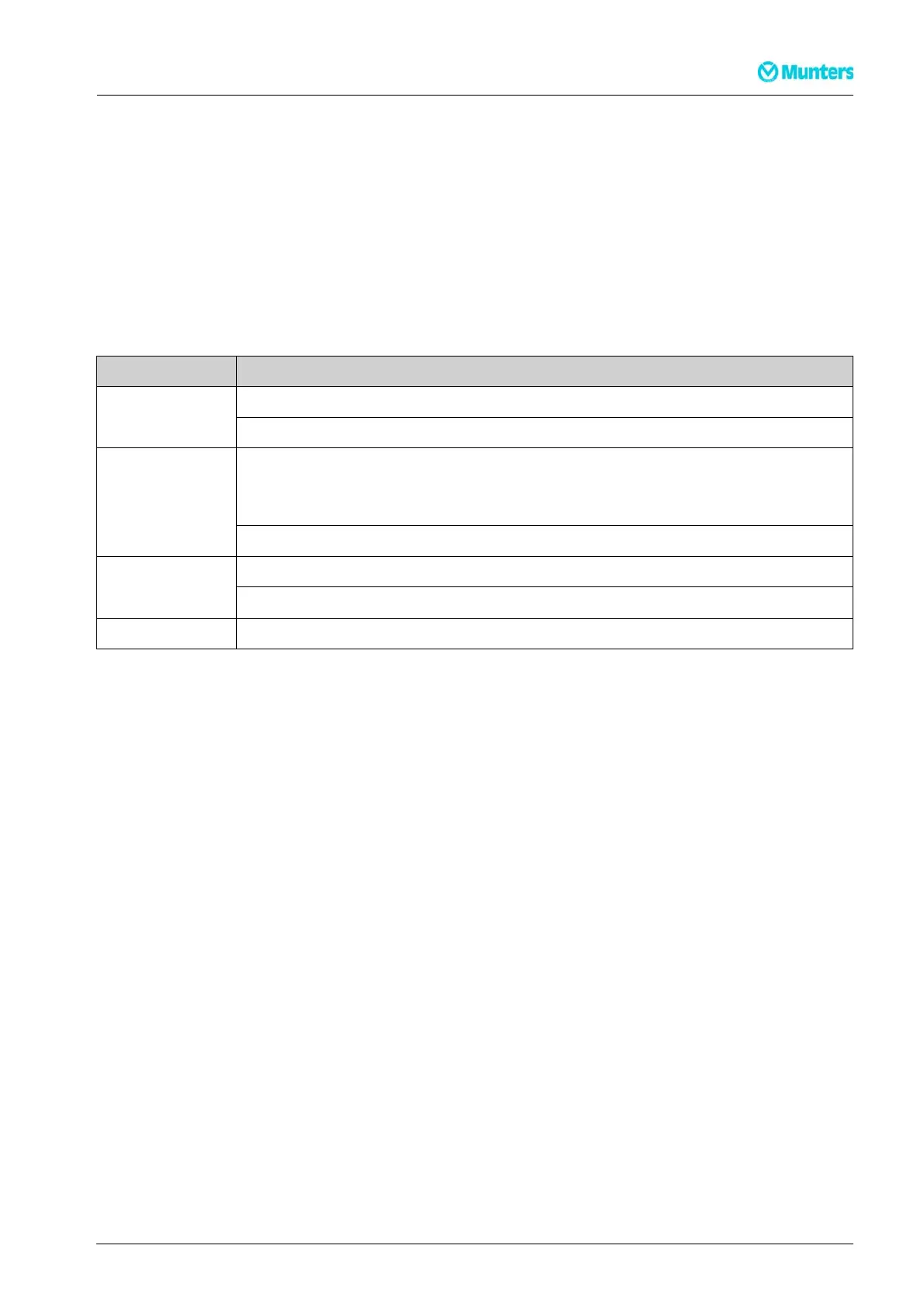

Serviceinterval Servicework

Makesurethatcorrectpressureisindicatedonthemanometer.Weekly

Examineallsteamconnectionsforleaks.

Examinetheheatercompartmentforsignsofcorrosionandscalebuild-up.

Allsignsofcorrosionmustbetreatedimmediately. Anyscaledepositsordirtaccumulated onthe

bottomoftheheatercompartmentshouldberemoved.

Monthly

Makesurethattheelectrical connectionsforthemodulatingvalvearesecure.

Examinethemodulatingvalve. Refertomanufacturer'stechnicaldocumentation.Six-monthly

Examine allfinned surfaces forcorrosion. Repair ifnecessary.

Annually Draintheheater. Examinethewaterforminutemagneticdeposits.

Table 6.3 Periodic maintenance for steam heater unit.

190TEN–108 9–G1412

Serviceandmaintenance

41

Loading...

Loading...