1.7 Steamsupply

The quality of water determines the quality of steam produced. It is important that a good quality steam

supply, at the correct temperature and pressure, is available for a reliable operation of t he steam heater.

Disregarding this can lead to degradation of the heater performance and eventually to failure.

The following impurities are common in the feed water:

■

Dissolved solids – which can cause scale to form on equipment. The principal dissolved solids are

carbonate and sulphates of calcium and magnesium.

■

Suspended solids – these can cause sludge to form in the boiler. Suspended solids are usually solid

mineral or org anic particles carried in suspension in the water.

■

Dissolved gases – these can cause corrosion in equipment. The dissolved g ases are oxygen and carbon

dioxide.

■

Frothing substances that can c ause contamination and corrosion of the equipment. The frothing

substances creates a foam that usually contains soda in the form of carbonates, chlorides or s ulphates.

Cor rect water treatment is required to remove the impurities in the feed water. If the impurities are not

removed there could be an overflow of boiler water into the steam s yste m .

1.8 Marking

1.8.1 Identificationplat

e

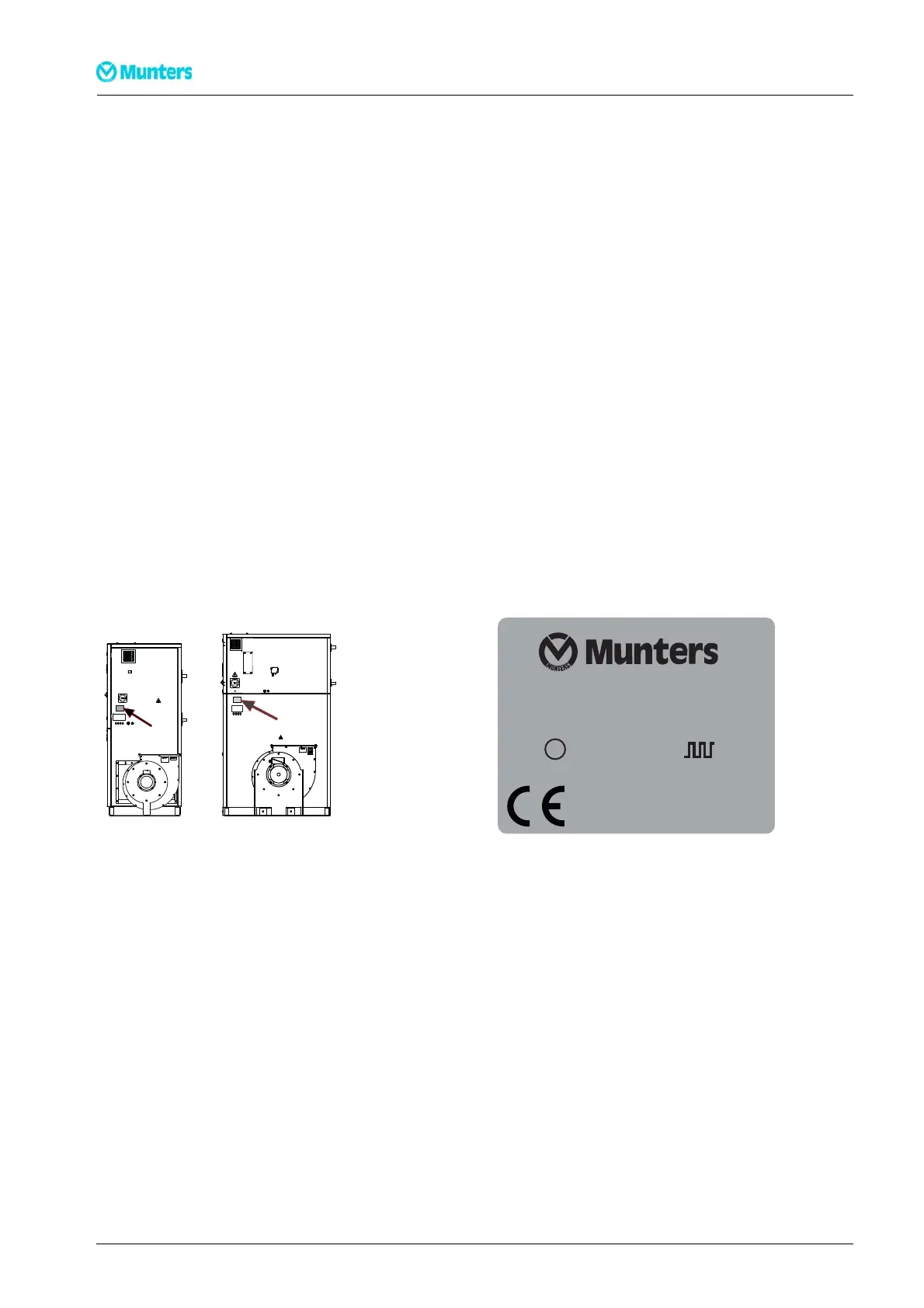

MX² 30S

MX² 35-95S

Figur e 1.3 Position of identification plat e

1005 170XXX XXXXX

4,1 kW

Max

4,6 kW

Munters Europe AB

Isafjordsgatan 1

164 26 Kista, Sweden

M

STEAM

Made in Sweden

Fabr. No.

Fabr. year 2010

3 ~ 400V 50 Hz

Type

IP33

MX² 55S

Figure 1.4 Identification plate, example

Explanation of "Fabr. No" on the identification plate:

10 Year of manufacture 170XXX Article number

05 Week of manufacture XXXXX Serial number

1.8.2 Pressuretestpoints

The built-in pressure t est points are used for measuring pressure drop across components during

basic installation work and inspection of the rotor condition. For airflow adjustment, refer to section

4.2, Airflow adjustment .

4

Introduction

190TEN–1089–G1412

Loading...

Loading...