2 Dehumidifierdesign

2.1 Productdescription

The desiccant dehumidifier has been designed to effectively dehumidify the air in environments requiring

low air humidity.

All functional components are enclosed in a corrosion resistant Aluzink

®

casing (standard) or stainless steel

casing (option) which makes installation and maintenance easy. The unit is constructed on a steel base frame

which allows the use of a fork-lift truck during transportation and installation.

The electrical control system complies with standard EN 60204-1. The electrical components are mounted

on bus bars. The dehumidifier is manufactured according to E uropean standards and the established

requirements for CE-marking.

2.2 Principleofoperation

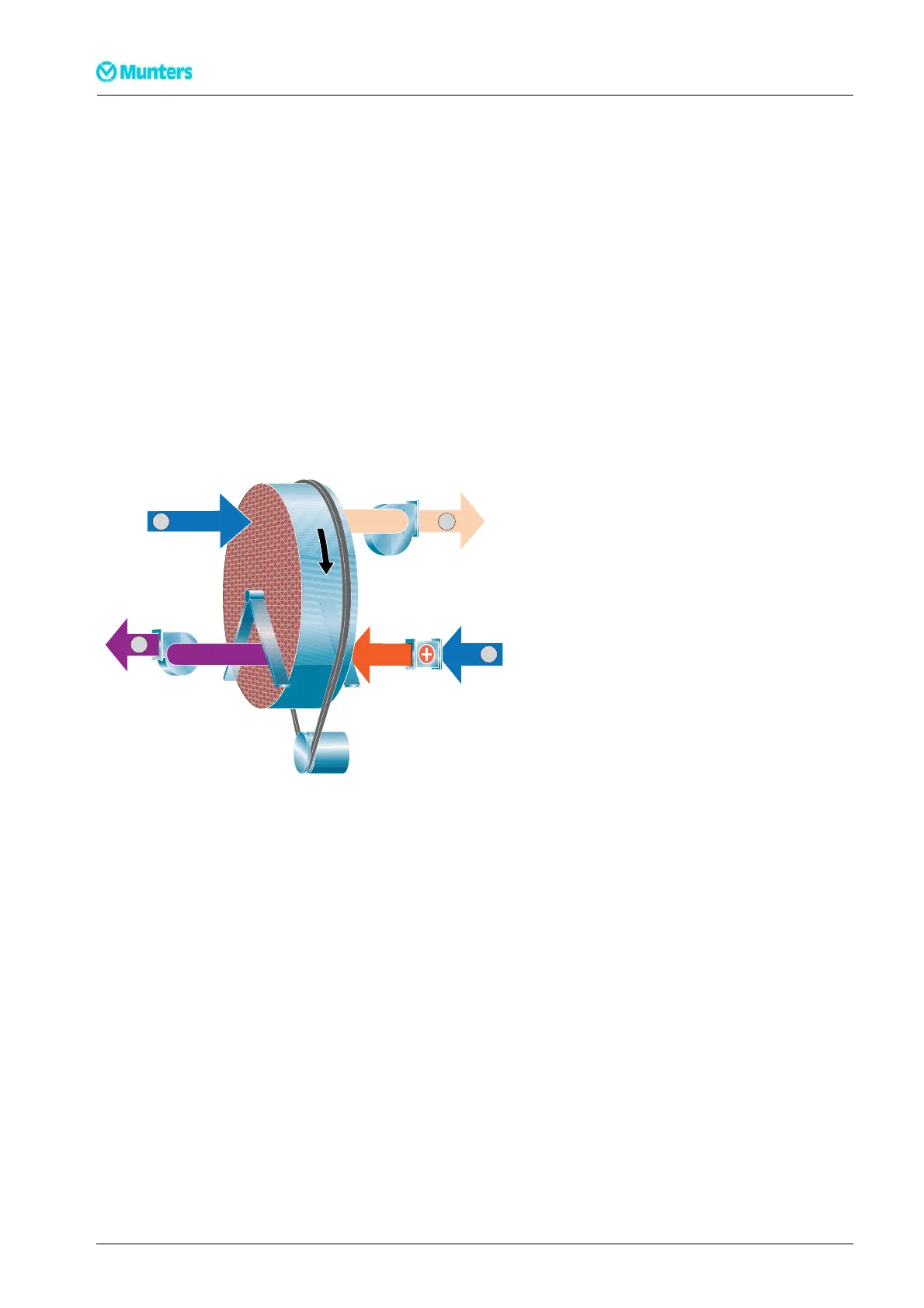

1

4

2

3

Figure 2.1 R otor principle

1. Process air

2. Dr y air

3. Reactivation air

4. Wet air

The desiccant rotor is the adsorption dehumidifying component in the unit. The rot or structure is

comprised of a large number of small air channels.

The desiccant rotor is made of a composite material that is highly effective in attracting and retaining water

vapour. T he rotor is divided in two zones. The airflow to be dehumidified, process air, passes through the

largest zone of the rotor and then leaves the rotor as dry air. Since the rotor rotates slowly, the incoming air

always meets a dry zone on the rotor, thus creating a continuous dehumidification process.

Theairflow tha t is used to dry t he rotor, r e a c tivation air, is heated. The reactivation air passes through

the rotor in the opposite direction to the process air and leaves the rotor a s wet air (warm, moist air). This

principle enables t he dehumidifier to work effectively, even at freezing temperatures.

6

Dehumidifierdesign

190TEN–1089–G1412

Loading...

Loading...