© by NECTA VENDING SOLUTIONS SpA

8

0210 206-00

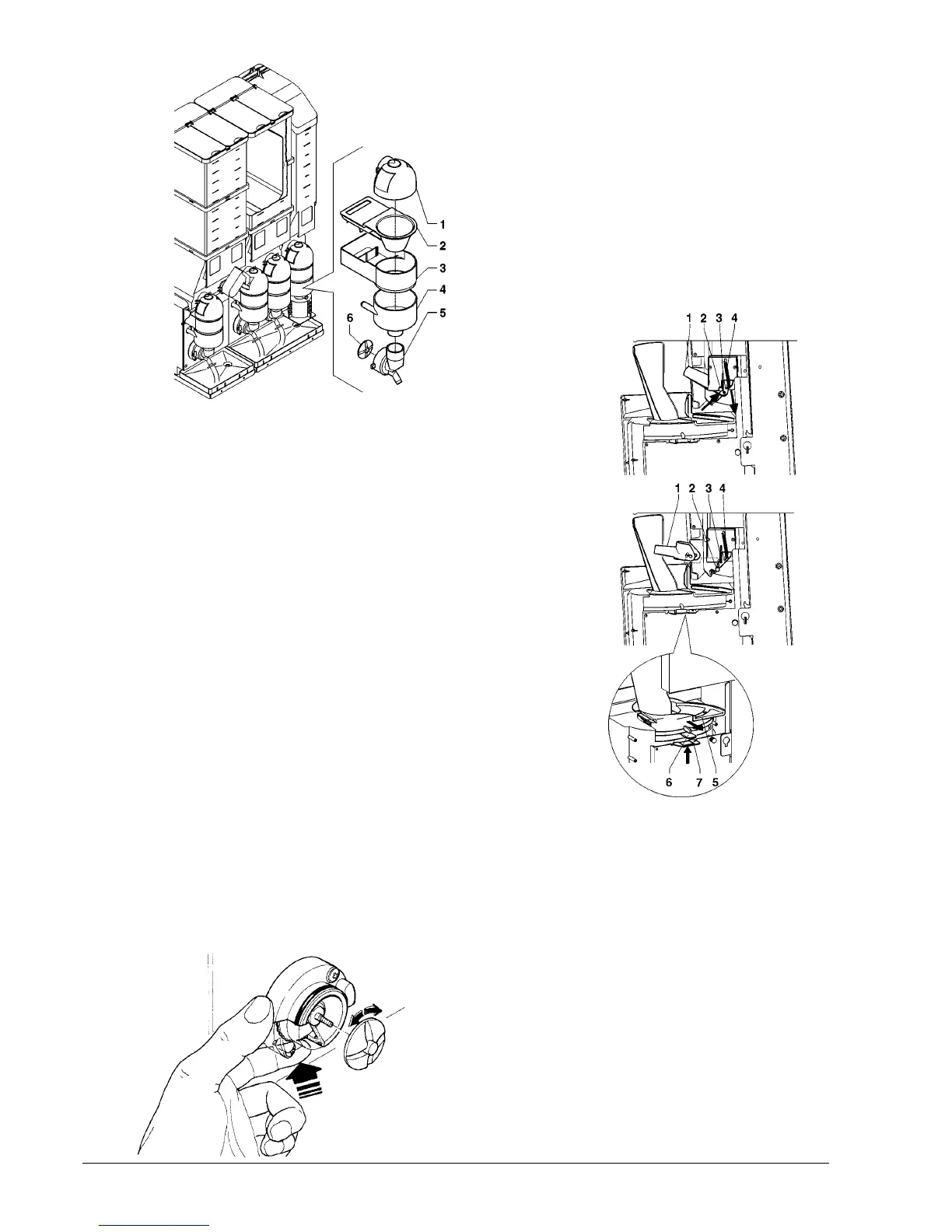

Fig. 9

CLEANING THE SUGAR DISPENSER

For models with sugar dispensed directly into the cup, the

sugar dispensing system must be cleaned periodically

using hot water (see figure 9) proceeding as follows:

- release the return spring;

- lift the flexible lever to free the pin;

- remove the pin and the dispensing spout;

- thoroughly rinse and dry;

- after cleaning, reinstall all parts in the reverse order.

1 - Sugar dispensing spout

2 - Pin

3 - Flexible lever

4 - Return spring

5 - Cup chute

6 - Cup chute release lever

7 - Chute positioning catch

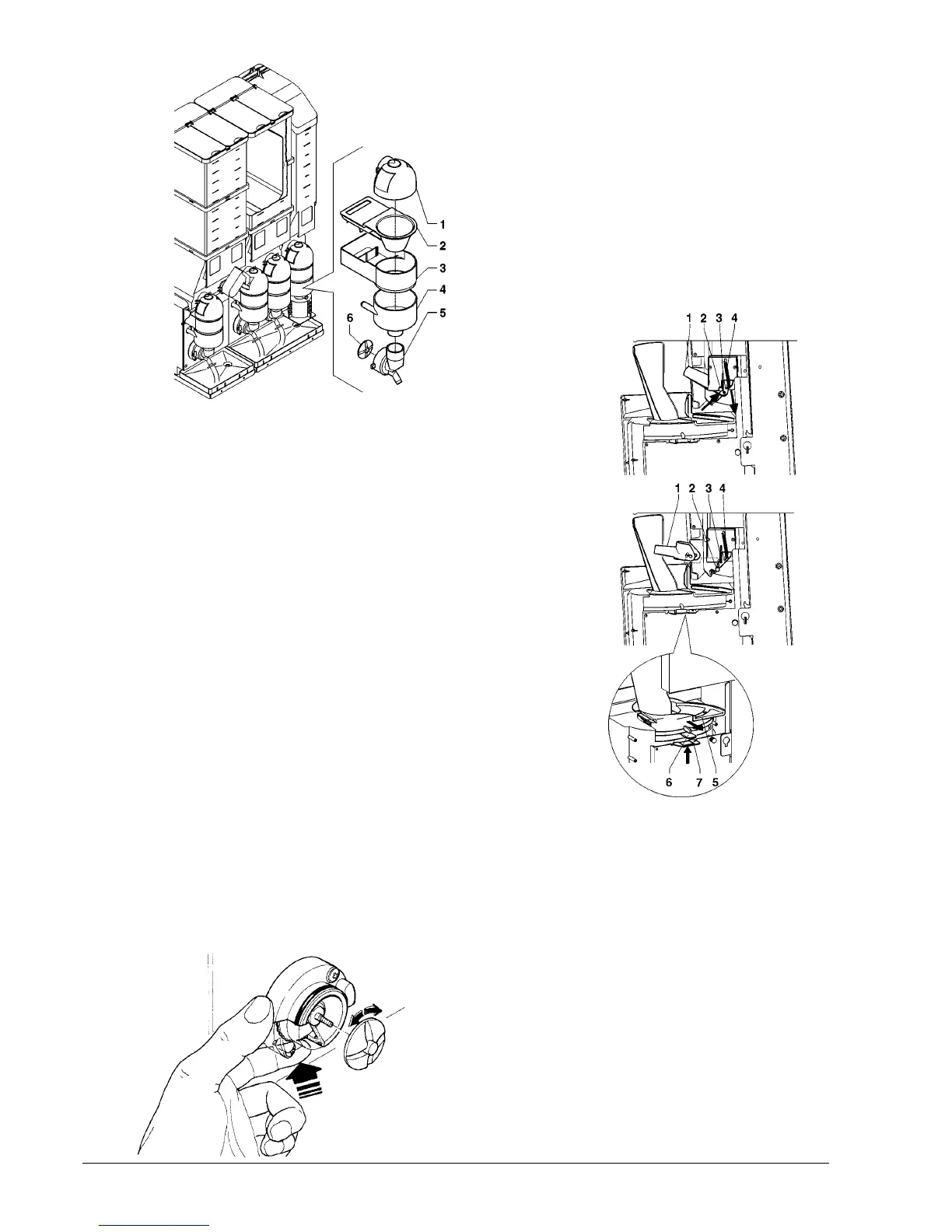

- in order to remove the wheels, block the disk fitted on the

mixer shaft with a finger;

- wash all parts with detergent being sure that all visible

residue (following the dose recommended by the manu-

facturer), and product layers are mechanically removed,

using a brush if necessary;

Disinfection should be carried out using chlorine-based

detergents;

- soak all components for approx. 20 minutes in a container

filled with the previously prepared chlorine-based deter-

gent;

- reinstall the feeders and the water funnels;

- reinstall the powder deposit drawers and the powder

funnels after thoroughly rinsing and drying them.

After reinstalling all parts the following is however

required:

- enter into "Filler menu" mode to clean the mixers (see

relevant paragraph) and add a few drops of the chlorine-

based detergent in the various funnels.

- After disinfection thoroughly rinse all components to

ensure that all residue of the detergent solution is re-

moved.

1 - Powder feeder

2 - Powder funnel

3 - Powder deposit drawer

4 - Water funnel

5 - Mixer feeder

6 - Mixer rotor

Fig. 7

Fig. 8

WEEKLY CLEANING OF

THE COFFEE UNIT

Every time coffee is refilled, or at least once a week, any

powder residue should be removed from the external parts

of the coffee unit, particularly from the coffee funnel.

Loading...

Loading...