© by NECTA VENDING SOLUTIONS SpA

26

0210 206-00

PRINTED BOARD FUNCTIONS

AND INDICATOR LIGHTS

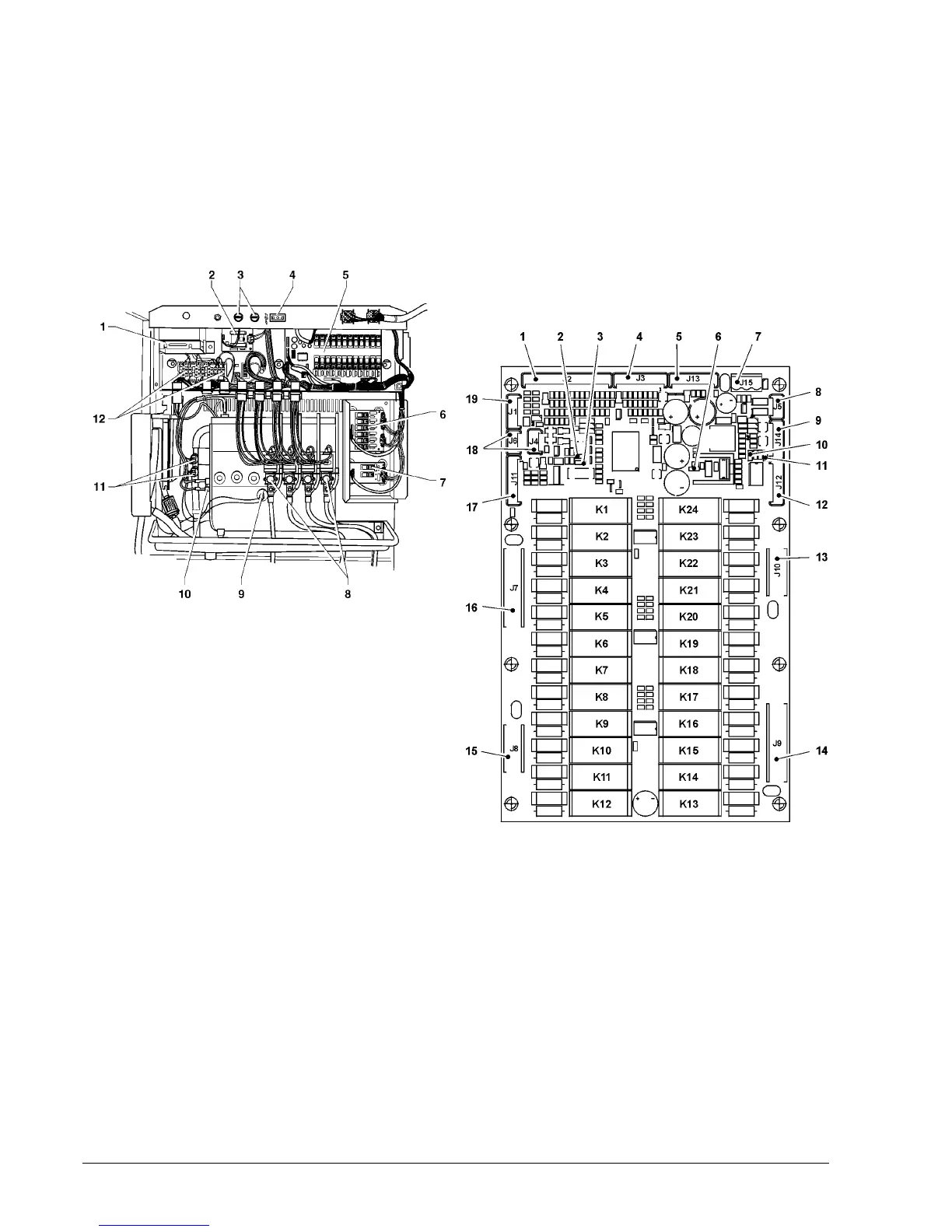

ACTUATION BOARD

This board (see Fig. 25) activates, by means of relays, the

230V~ components of the machine. It controls the signals

from the cams and/or microswitches fitted on the various

users. It also controls the boiler board and the relay

boards.

This board is powered with 24 V AC.

Fig. 25

The board control software is loaded directly onto the

microprocessor (through RS232).

- Green LED (2) blinking during the normal operation of the

board

- Yellow LED (6) indicating the presence of 5 V DC

- Red LED (3) glowing during the board reset

- Red LED (10) indicating the operating status of the

Espresso boiler heating element.

RELAY FUNCTION (see Wiring diagram)

K1 = EEA

K2 = MSB

K3 = MSCB

K4 = MDZ

K5 = MSP

K6 = ESC2 VENT

K7 = MSU

K8 = PM MF3

K9 = MD1

K10 = MF1

K11 = MD2

K12 = MF2

K13 = E1

K14 = E2

K15 = E3

K16 = E4

K17 = E5

K18 = E6

K19 = LF

K20 = MAC MD4 MDFB

K21 = ESC MD5 MFB

K22 = ERE MF5 MPF

K23 = M MD3 MDFB

K24 = MAC2 MF4 MFFB

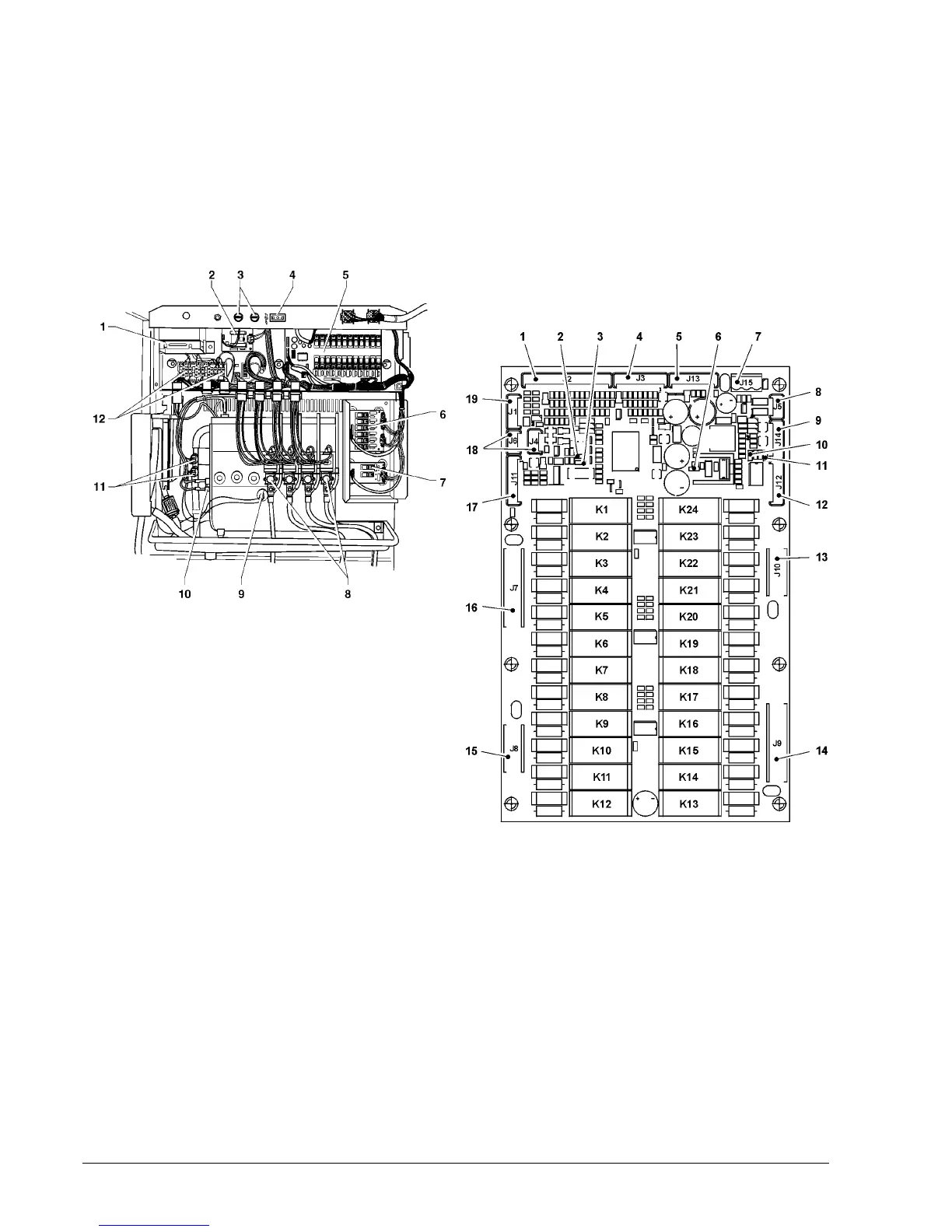

1 - Transformer

2 - Instant boiler board

3 - Network fuses

4 - Permanently live socket

5 - Actuation board

6 - 6-relay card

7 - 3-relay card

8 - Instant prod. solenoid valves

9 - Boiler temperature probe

10 - Safety thermostat (manual reset)

11 - Anti-boiling thermostats (manual reset)

12 - Transformer fuses

Fig. 26

1 - Input signals

2 - Green LED

3 - Red LED

4 - Input signals

5 - Connector for board programming (RS232)

6 - Yellow LED

7 - Board power supply (24 Vac)

8 - Not used

9 - Probe and boiler control

10 - Red LED: Espresso boiler heating element

11 - Red LED: Instant boiler heating element

12 - 6-relay card connection

13 - 230 V~ users

14 - 230 V~ users

15 - 230 V~ users

16 - 230 V~ users

17 - 3-relay card connection

18 - "Can Bus" connection

19 - Not used

Loading...

Loading...