12

© by NECTA VENDING SOLUTIONS SpA 09-2003 228 00

COFFEE UNIT OPERATION

COFFEE DISPENSING CYCLE

After each time the machine is switched on, upon the first

espresso coffee based selection, the coffee unit is rotated

completely before the normal cycle, too ensure that the

device is in the correct start position.

When selecting coffee, the grinder is started and will

continue until the coffee doser chamber is full (see Fig.

14).

When the doser unit is full, the ground coffee dose is

released into the coffee unit.

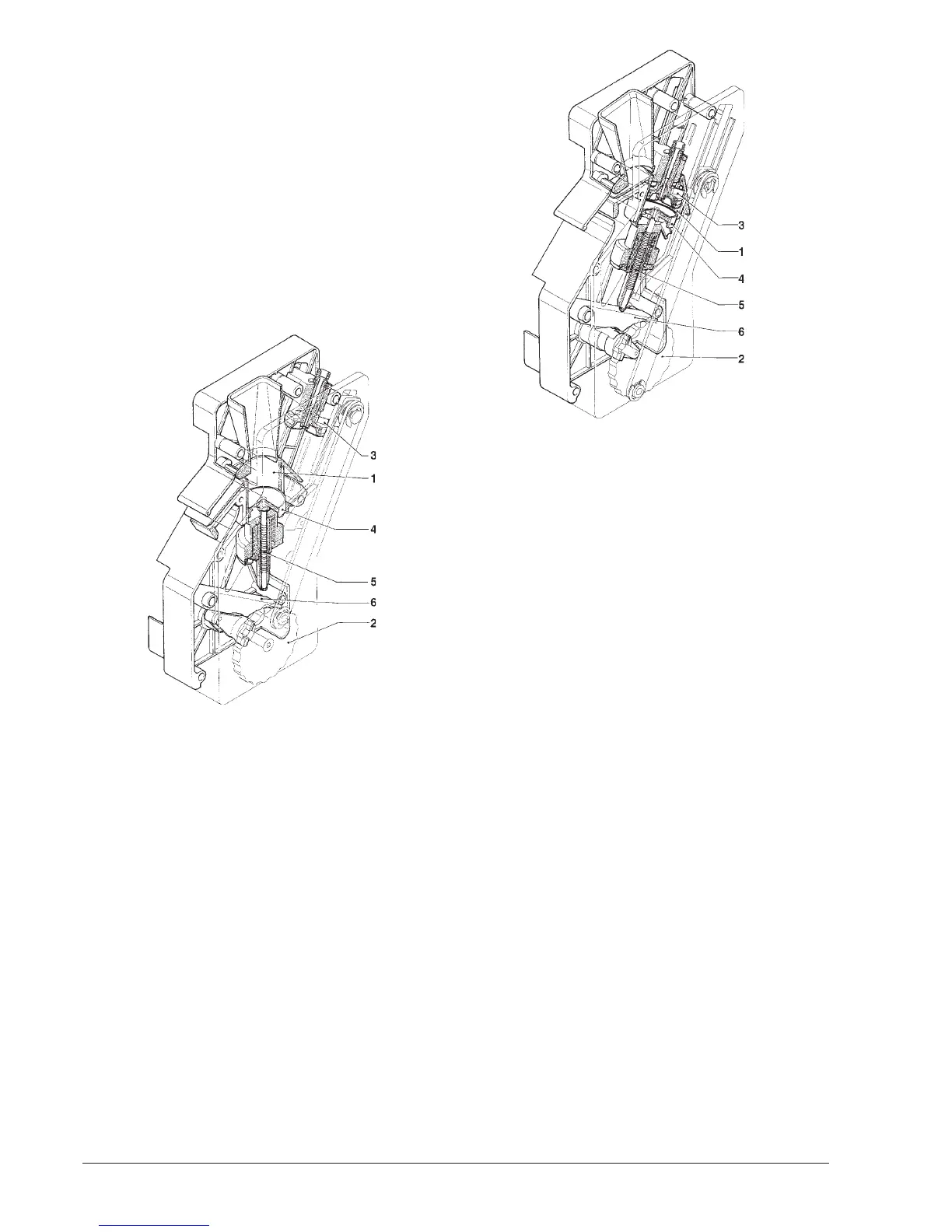

The coffee falls into the vertical brewing chamber (1) (see

Fig. 11).

The ratiomotor handle engaged with the disk (2) located

outside of the assembly rotates by 180°, making the

brewing chamber swing and lowering the upper piston (3).

Due to the water pressure, the pre-brewing spring (5)

sinks and the lower piston (4) goes down 4 mm, thus

forming a water cushion which allows an even use of the

coffee dose.

At the end of the dispensing cycle and during a pause of

3 seconds, the pre-brewing spring (5) will discharge the

water through the third way of the dispensing solenoid

valve, lightly pressing the used coffee dose.

By completing its rotation, the ratiomotor makes the

swinging lever (6) lift the pistons and the tea dose.

At the same time, when the brewing chamber returns to

its vertical position, the scraper on the coffee hopper stops

the used coffee dose and drops it.

The lower piston now returns to the bottom dead centre.

Fig. 11

1 - Brewing chamber

2 - External disk

3 - Upper piston

4 - Lower piston

5 - Pre-brewing spring

6 - Swinging lever

CHECKING AND ADJUSTING

THE MACHINE SETTINGS

To get the best results from the product used, the following

should be checked:

For coffee

That the used coffee dose is lightly compressed and

damp.

The grade of grinding of ground coffee.

The dose weight of ground coffee.

The dispensing temperature.

The water dose.

For instant products

The dose weight of the instant products.

The drink temperature.

The water dose.

Should the standard settings need to be changed, proceed

as indicated in the next sections of this manual.

The weight of instant products, the water dose and

temperature are directly controlled by the microproces-

sor.

To adjust them it is therefore necessary to follow the

programming procedures.

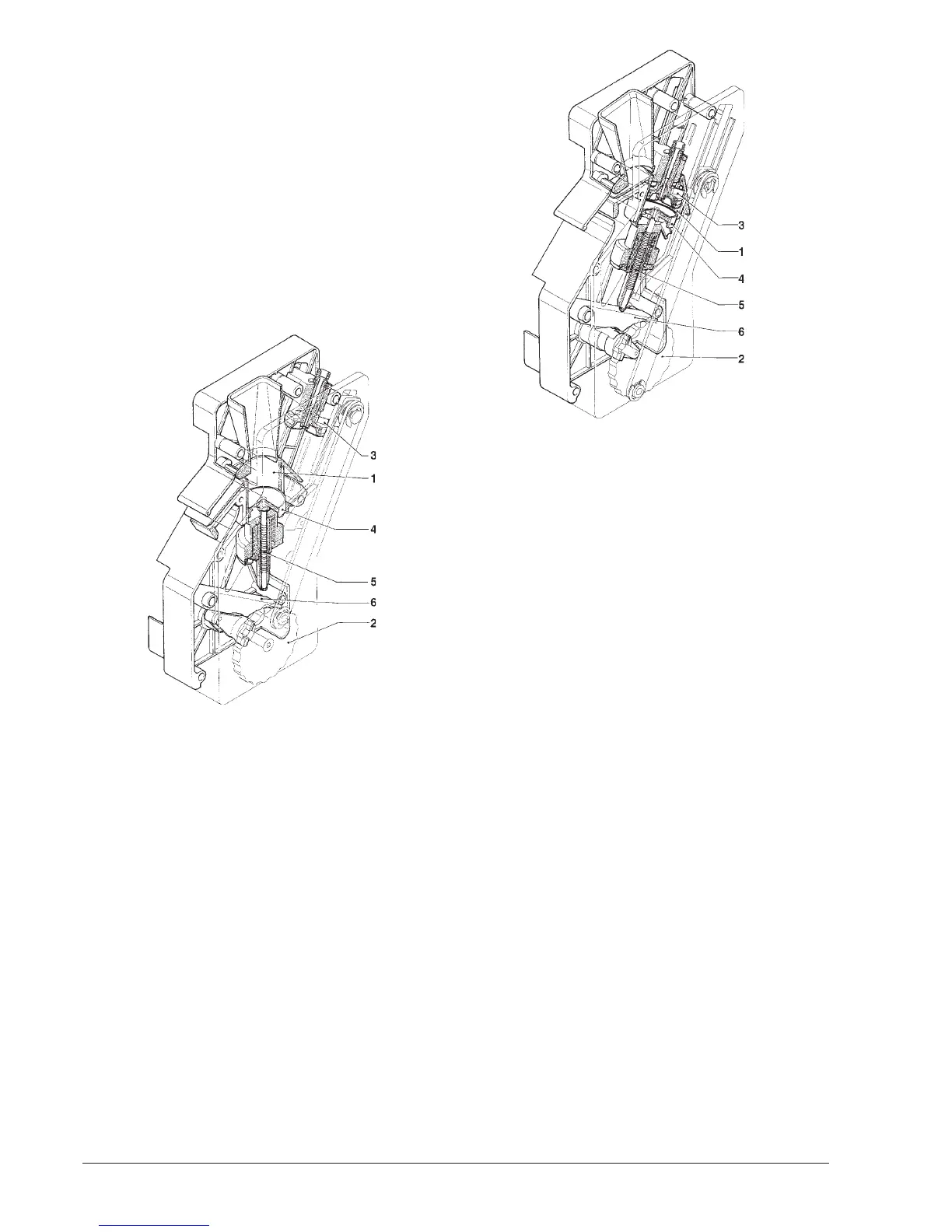

Fig. 12

1 - Brewing chamber

2 - External disk

3 - Upper piston

4 - Lower piston

5 - Pre-brewing spring

6 - Swinging lever

Loading...

Loading...