44 EN Operating instructions

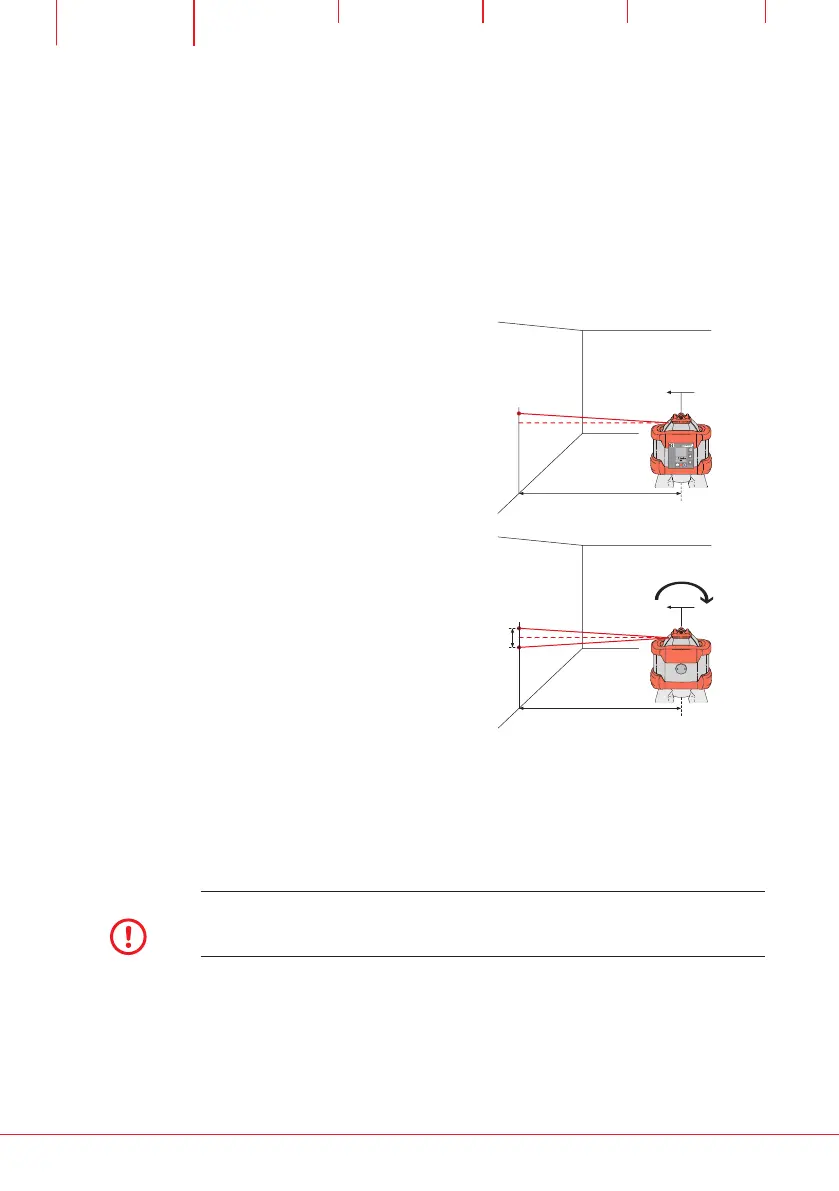

Step 2 – X-axis

• Rotate the axis through 180°.

Attention:

The tripod may not be changed

– ideally you should use Nedo

Quickfix®!

• Mark position B of the laser

beam and measure the verti-

cal distance H between marking

A and marking B. This can be

above or below marking A.

• The laser is within the tolerance if

H 3 mm!

30 m

A

X

B

H

NOTE

Steps 1 and 2 now have to be repeated as described for the Y-axis.

If the value of H is outside the tolerance, the Primus 2 must be adjusted by an autho-

rised customer service agent or by Nedo.

14.3 Checking the horizontal accuracy

The accuracy of the laser should be checked regularly. This requires a free

measuring length of 30 m. Four measurements are taken in total in AUTOMA-

TIC mode (two measurements each in X/Y axis). The check is carried out in

two steps. The position of the laser beam is determined with the help of the

receiver.

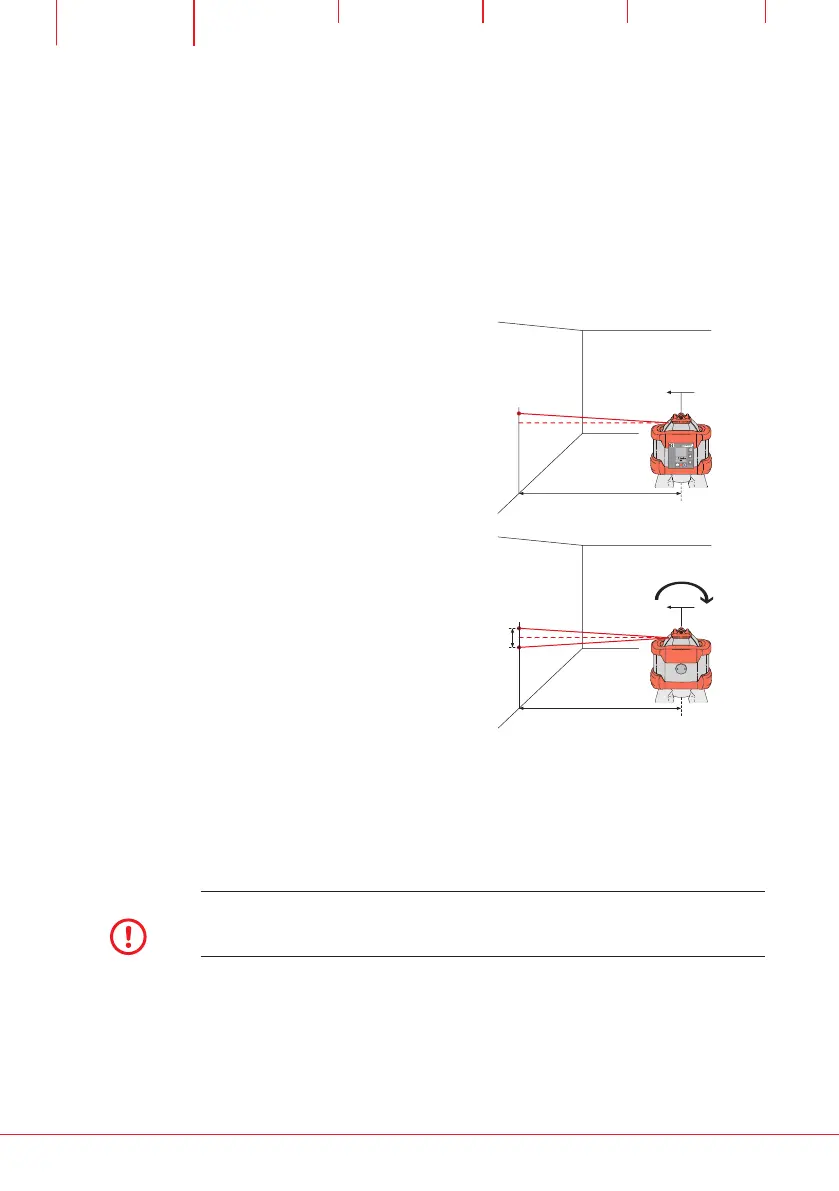

Step 1 – X-axis

• Set up the laser along the X-axis

with a 30 m distance from the

wall.

• Mark the position of the laser

beam (A) on the wall.

LASER RADIATION

AVOID DIRECT EYE EXPOSURE

CLASS 3R LASER PRODUCT

max. 5mW 630-650nm

DIN EN 60825-1:2007

30 m

A

X

Loading...

Loading...