General pipe connections

Pipe installation must be carried out in accordance with

current norms and directives.

The system requires the radiator circuit to be designed

for a low temperature heating medium. At the lowest

dimensioned outdoor temperature (DOT) the highest

recommended temperatures are 55 °C on the supply

line and 45 °C on the return line.

Overflow water from the evaporator collection tray and

safety valves passes via a non-pressurised pipe to an

overflow cup, and from there to a drain, so that hot wa-

ter splashes cannot cause injury. The entire length of the

overflow water pipe must be inclined to prevent water

pockets and must also be frost-proof.

NOTE

The pipe system needs to be flushed out before

the heat pump is connected so that any debris

cannot damage component parts.

Caution

Ensure that incoming water is clean. When using

a private well, it may be necessary to supple-

ment with an extra water filter.

Maximum boiler and radiator volumes

The volume of the pressure expan-

sion vessel (CM1) is 10 litres and it

is pre-pressurised as standard to 0.5

bar (5 mvp). As a result, the maxim-

um permitted height "H" between

the vessel and the highest radiator

is 5 m, see figure.

If the standard initial pressure in the

pressure vessel is not high enough

it can be increased by adding air via

the valve in the expansion vessel.

The initial pressure of the expansion

vessel must be stated in the inspec-

tion document. Any change in the

initial pressure affects the ability of the expansion vessel

to handle the expansion of the water.

The maximum system volume excluding the boiler is 219

litres at the above pre-pressure.

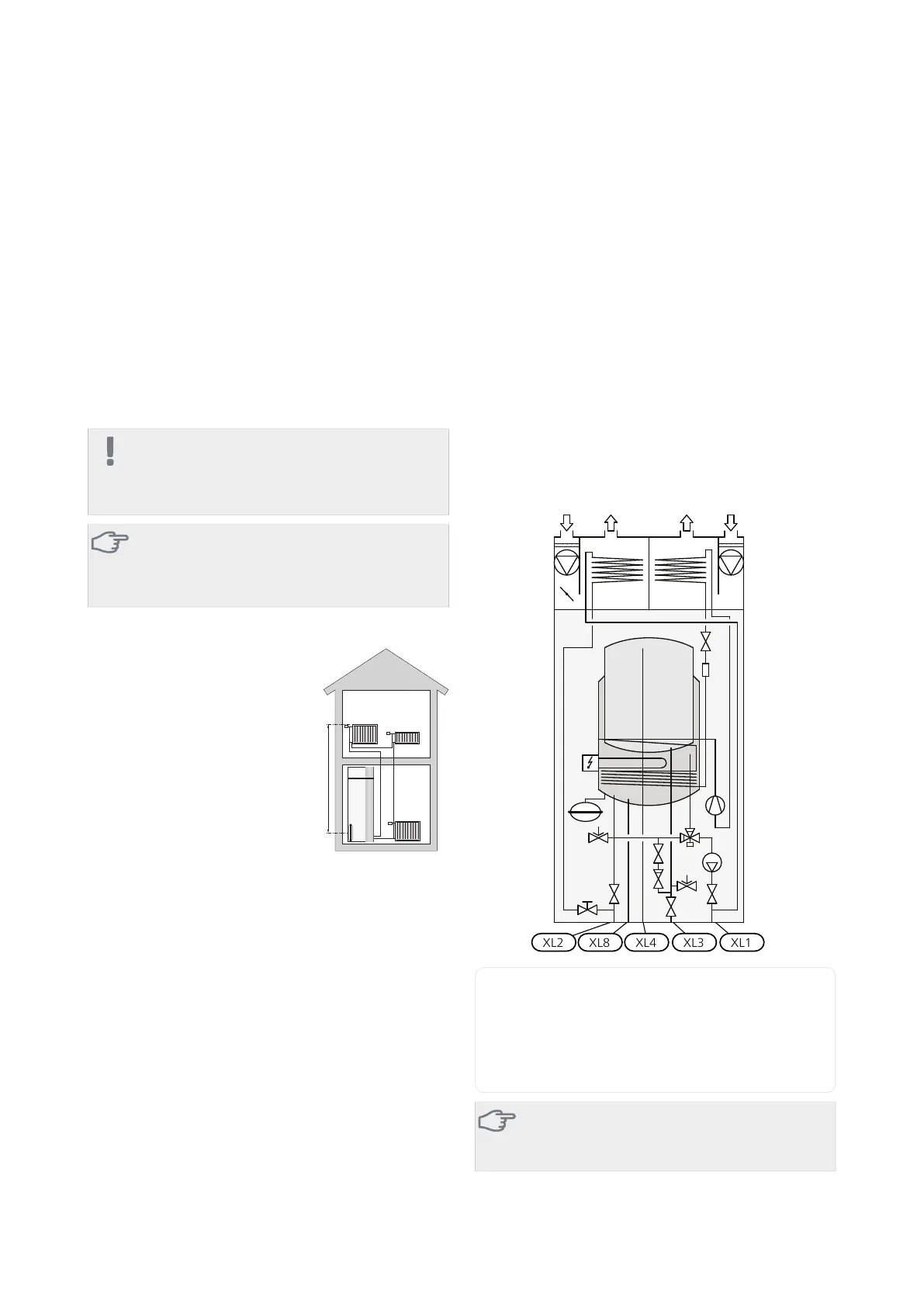

System diagram

F470 consists of a heat pump, water heater, immersion

heater, fans, circulation pump and control system.F470

is connected to the ventilation system and heating me-

dium circuit.

When the exhaust air at room temperature passes

through the evaporator, the refrigerant evaporates be-

cause of its low boiling point. In this way the energy in

the room air is transferred to the refrigerant.

The refrigerant is then compressed in a compressor,

causing the temperature to rise considerably.

The warm refrigerant is led to the condenser. Here the

refrigerant gives off its energy to the heating system

water, whereupon the refrigerant changes state from

gas to liquid.

The refrigerant then goes via filters to the expansion

valve, where the pressure and temperature are reduced.

The refrigerant has now completed its circulation and

returns to the evaporator.

Connection, heating medium flowXL1

Connection, heating medium returnXL2

Connection, cold waterXL3

Connection, hot waterXL4

Connection, dockingXL8

Caution

This is an outline diagram, differences may occur

in the actual installation.

NIBE F470Chapter 4 | Pipe and ventilation connections16

4 Pipe and ventilation connections

Loading...

Loading...