12

13 - GATE BRACKET MOUNTING

14 - LIMIT SWITCH ADJUSTMENT

Pull to Open only: Activate push button on the side of the control box and extend the actuator until it stops (leave actuator

retracted for PUSH TO OPEN).

WARNING: Do not let extension tube rotate as it extends. Do not insert ngers or tools in the hole at the end of the

extension tube.

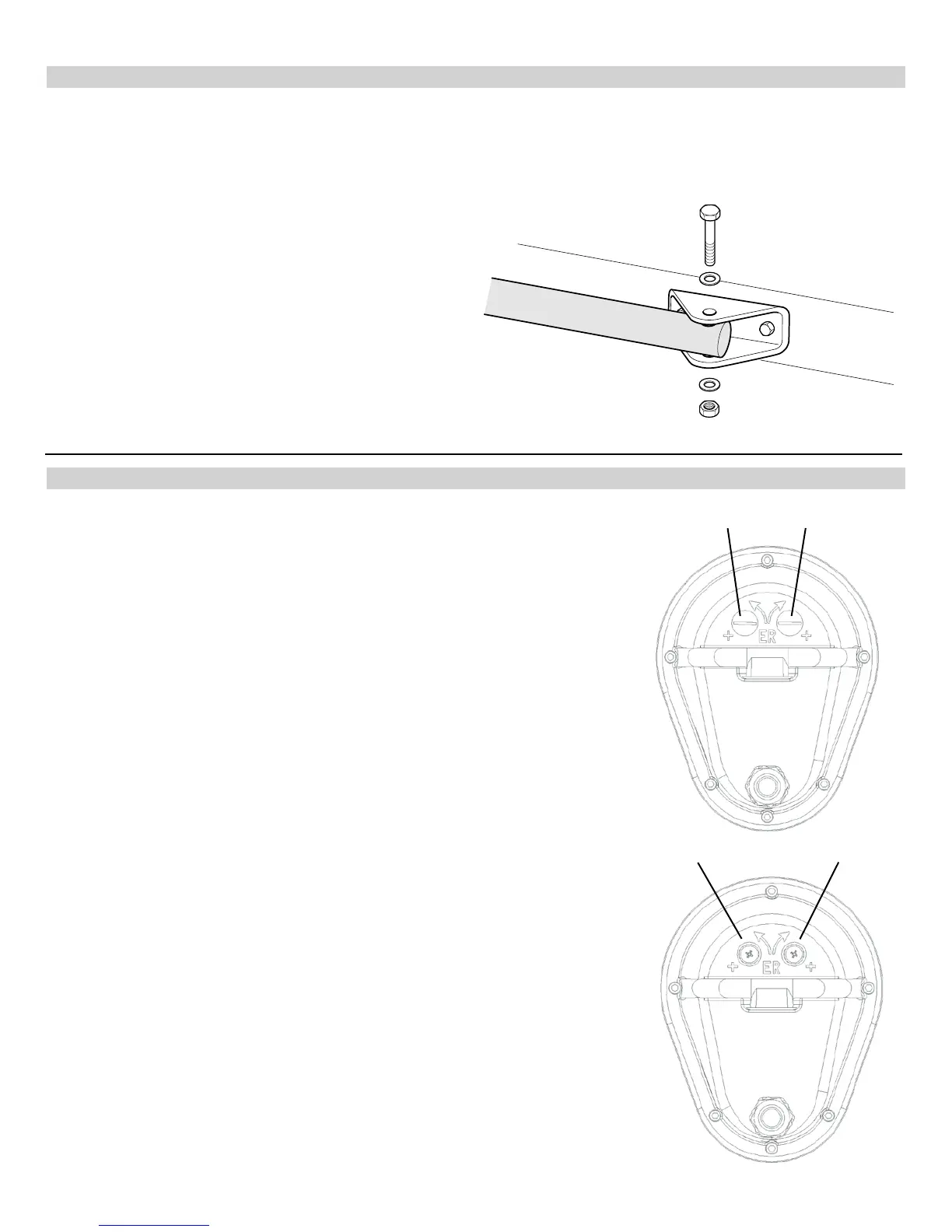

Connect the gate bracket to the end of the extension tube

with supplied 1/2” x 3” bolt. With the gate in the closed

position, place the gate bracket on the gate and mark

placement or secure with a clamp. Unbolt and remove

the extension tube from the bracket and weld or bolt the

bracket to the gate using 3/8” bolts, lock washers, and

nuts.

Bolt the actuator to the gate bracket as shown.

Tip: Tack weld or C clamp at rst if uncertain about location.

Run the unit through a complete cycle to insure proper

operation then mount permanently .

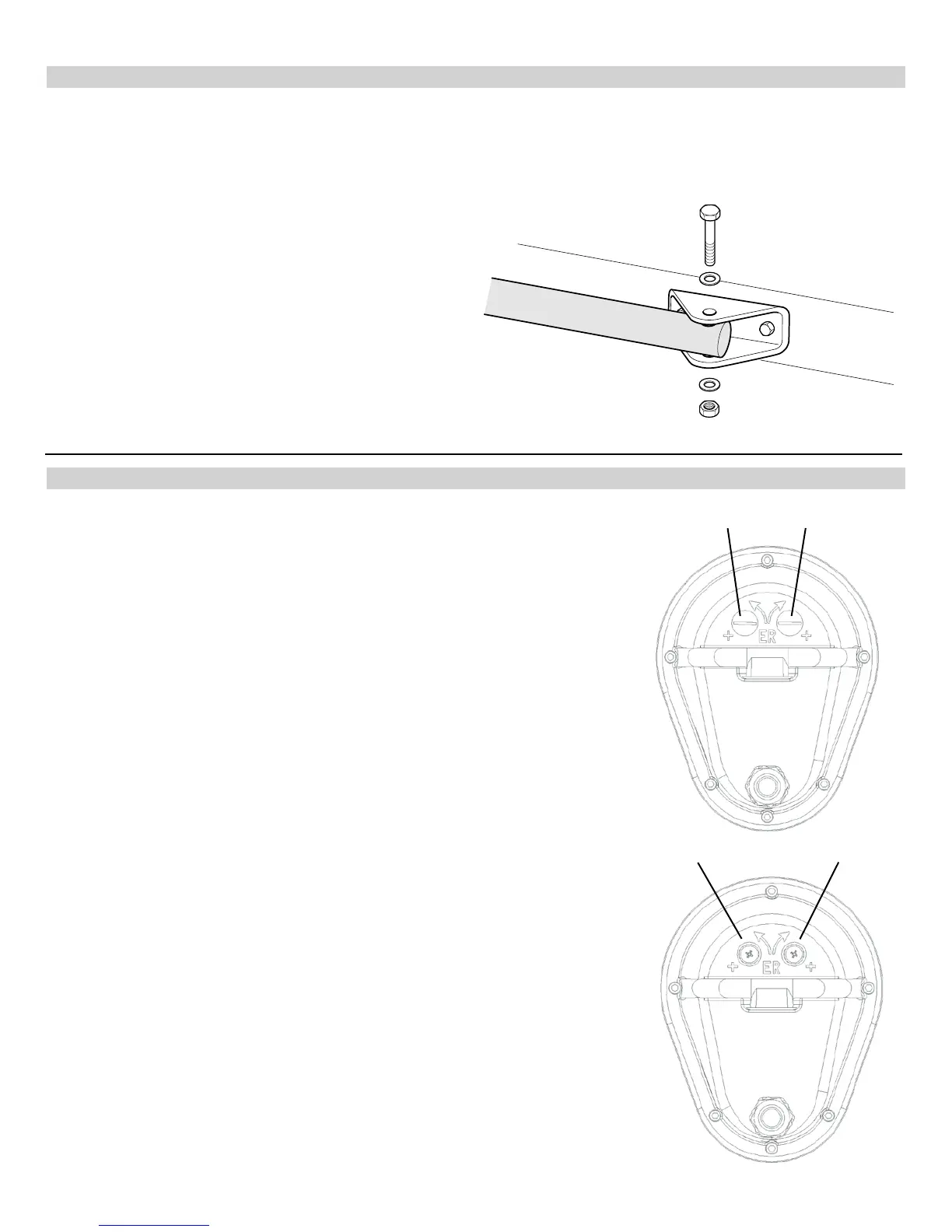

14.1 - Model 1500 (single gate operator)

Remove the limit screw end caps. A shown in the gure to the right.

With the gate in the closed position depress the LED ENABLE button on the

circuit board. You should see the MASTER CLOSE limit LED illuminate. Using

the black button on the side of the control box cycle the operator to the open

position. If the actuator does not stop before reaching the fully open position

depress the black button to stop the motor in the desired open position. Adjust

the retract (pull to open) or extend (push to open) limit as shown in the gure

below. Turn the limit correct screw until the MASTER OPEN limit LED illuminates

(while holding the LED enable button).

Do not extend the extension tube too far or you will risk unscrewing the tube

from the main drive screw.

*Maximum extension length is 66”*

EXTEND more: Turn the limit screw counterclockwise

EXTEND less: Turn the limit screw clockwise

RETRACT more: Turn the limit screw clockwise

RETRACT less: Turn the limit screw counterclockwise

Remove limit switch end caps

Extend limit screw Retract limit screw

14.2 - Model 1600 (dual gate operator)

Follow the steps above to set the master gate actuator while leaving the slave

gate actuator disconnected. Once the master gate actuator is set, disconnect the

master gate actuator and plug the slave gate harness into the master side of the

circuit board. Follow the same steps to set the limits on the slave gate actuator.

Once both actuators are set, plug the master gate actuator into the master side

of the board and slave gate actuator into the slave side of the board.

As you open and close the gates, you will notice that the slave side moves 2-3

seconds slower than the master. This is normal due to the length of cable on the

slave gate actuator.

Loading...

Loading...