9 F600 Step By Step Guide

STEP 6: Wire the drive up

This step covers connection of input power connection L1,L2, and L3 including the ground terminals,

motor phases U V W and the control terminals.

The tools required for this are terminal screwdriver, flat screwdriver, M7, M8, M10 and M17 sockets

T20 and T25 driver. When wiring the drive’s power, ground and control connections, they should be

tightened to the recommended torque settings shown in the table below:

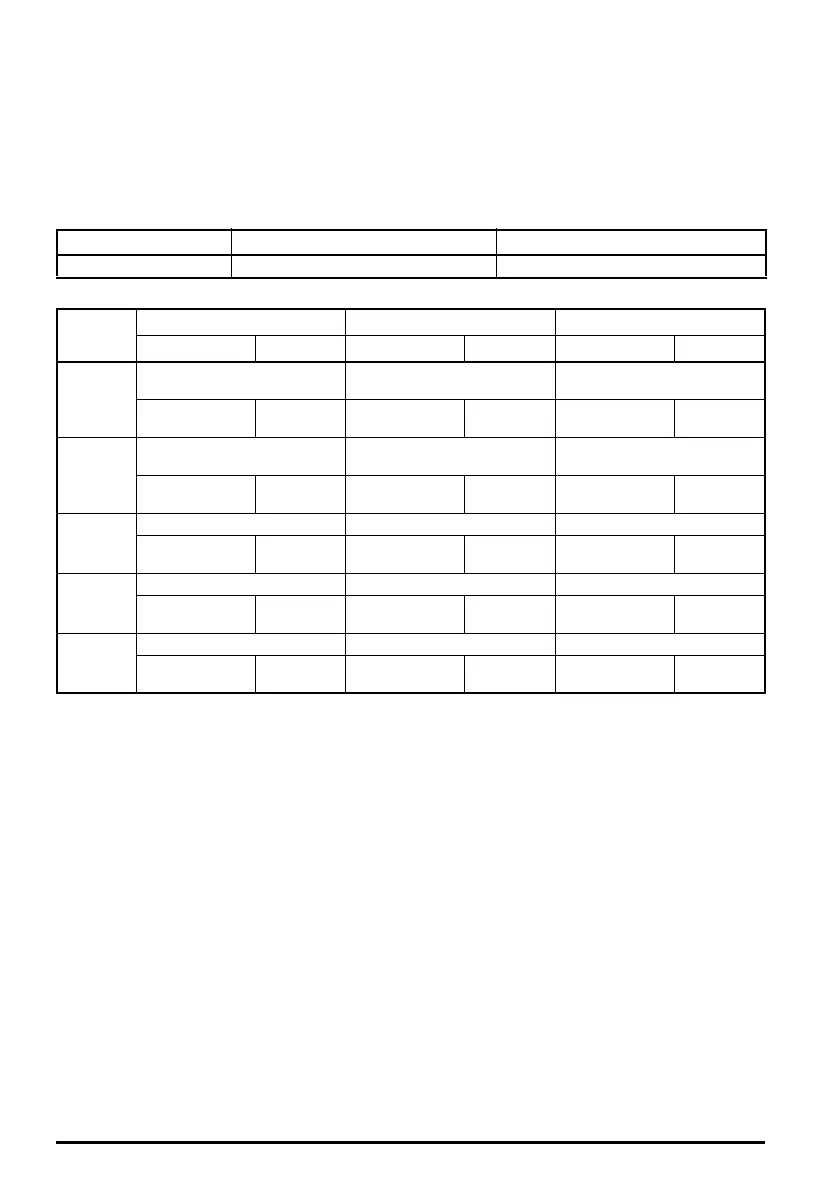

Table 6-1 Drive control and relay terminal data

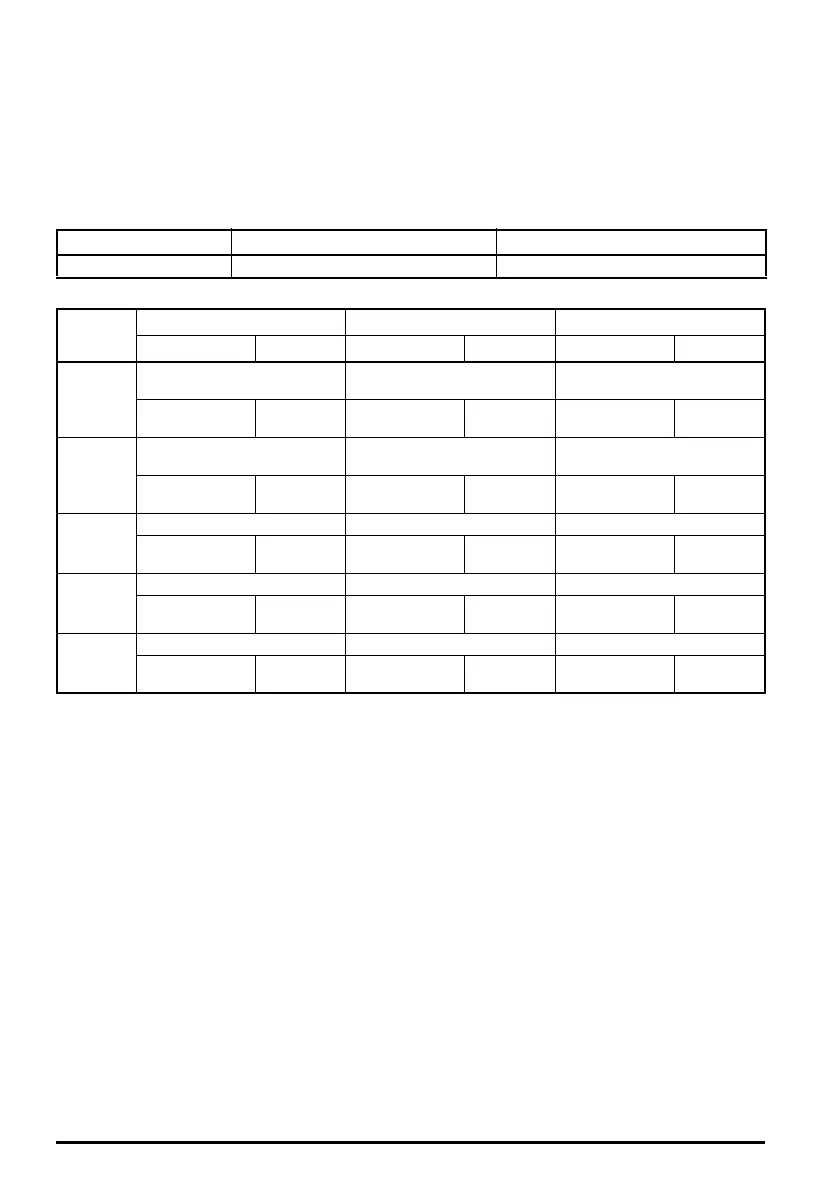

Table 6-2 Drive power terminal data

Power and Ground connections

Connect the supply and motor connections using the cables and fuses quoted in the table shown in

Step 4.

Model Connection type Torque settings

All Plug-in terminal block 2.0 N m (1.4 lb ft)

Model

size

AC and motor terminals DC terminal Ground terminal

Recommended Maximum Recommended Maximum Recommended Maximum

3 and 4

Plug-in terminal block T20 Torx (M4)

T20 Torx (M4) / M4 Nut

(7 mm AF)

0.7 N m

(0.5 lb ft)

0.8 N m

(0.6 lb ft)

2.0 N m

(1.4 Ib ft)

2.5 N m

(1.8 Ib ft)

2.0 N m

(1.4 Ib ft)

2.5 N m

(1.8 Ib ft)

5

Plug-in terminal block

T20 Torx (M4) / M4 Nut

(7 mm AF)

M5 Nut (8 mm AF)

1.5 N m

(1.1 lb ft)

1.8 N m

(1.3 lb ft)

1.5 N m

(1.1 lb ft)

2.5 N m

(1.8 Ib ft)

2.0 N m

(1.4 Ib ft)

5.0 N m

(3.7 Ib ft)

6

M6 Nut (10 mm AF) M6 Nut (10 mm AF) M6 Nut (10 mm AF)

6.0 N m

(4.4 Ib ft)

8.0 N m

(6.0 Ib ft)

6.0 N m

(4.4 Ib ft)

8.0 N m

(6.0 Ib ft)

6.0 N m

(4.4 Ib ft)

8.0 N m

(6.0 Ib ft)

7

M8 Nut (13 mm AF) M8 Nut (13 mm AF) M8 Nut (13 mm AF)

12 N m

(8.8 Ib ft)

14 N m

(10.0 Ib ft)

12 N m

(8.8 Ib ft)

14 N m

(10.0 Ib ft)

12 N m

(8.8 Ib ft)

14 N m

(10.0Ibft)

8 to 11

M10 Nut (17 mm AF) M10 Nut (17 mm AF) M10 Nut (17 mm AF)

15 N m

(11.1 Ib ft)

20 N m

(14.8 Ib ft)

15 N m

(11.1Ibft)

20 N m

(14.8 Ib ft)

15 N m

(11.1Ibft)

20 N m

(14.8Ibft)

Loading...

Loading...