15Service Manual – SC900 20 - Wheel System, Traction

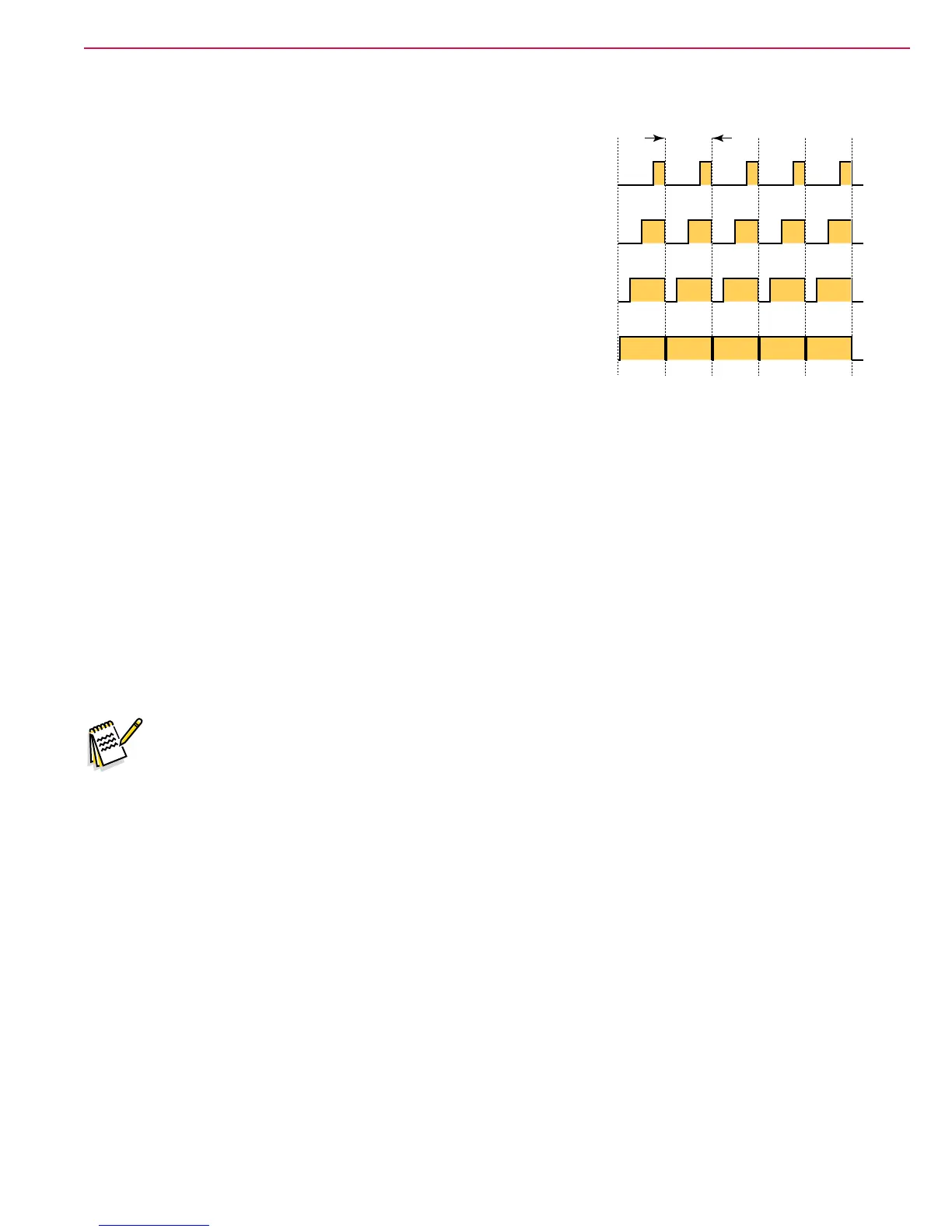

Drive Motor PWM Function

The drive motor is controlled from a Curtis 1228 controller, which is

a pulse-width-modulation speed controller designed specically for

permanent magnet DC motors. Pulse-width-Modulation (PWM) is a form

of motor speed control that alters the power to a motor by rapidly turning

the power on and off. The ratio (also called “duty cycle”) between the

On and Off states determines how much power the motor receives. The

shorter the “off-time” the closer to full power the motor will receive. This

switching occurs so fast (15kHz for this controller) that the motor simply

sees it as a reduction in power (voltage) instead of the rapid on/off. PWM

is a standard motor control technique because it is easier to turn power

all the way on and all the way off, than it is to vary the magnitude of the

power. Varying the magnitude would create a lot of heat that would need

to be dissipated.

Drive Controller

The primary purpose of the drive controller is, of course, to control the drive motor. However, it also provides

some ancillary control of the other functions of the machine, which will be discussed in greater detail in the

applicable chapters. As a motor controller, it delivers PWM-varying power to the drive motor in both positive

and negative polarities for forward and reverse motor operation.

Even though the machine does not utilize an electromechanical brake system, the drive controller possesses

the output control for one. This is used for ancillary machine control. This is more aptly referred to as a

Brake-Release versus a brake control. Whenever the machine is not commanded to move, the brake outputs

are inactive, and if a brake was present, it would be mechanically engaged. The brake outputs are active

only when the machine is commanded to move. This feature is used to activate the scrub functions of the

machine only when the machine is commanded to move (even if the speed is set to zero).

The controller is powered directly from the batteries, but through a 30-amp circuit breaker. The drive

controller remains inactive (inhibited) until the KSI input receives positive battery power through the main

key switch. When KSI is active, the drive is ready to operate, and awaiting a throttle command to move.

Note: The drive controller is congured for an inverted throttle input from typical. Instead of the

throttle being active-high, it is active-low. When the throttle input is at 5 volts, the throttle is

off. When the throttle input is at 0 volts, the drive is commanded for full throttle.

In addition to the throttle being inverted, it is also limited to just two states: Off and Full. Because the

throttle input is either off or full, the speed of the machine is controlled by the speed limit potentiometer

input. This input ranges from 0 to 5 volts, with 0 volts equaling no speed, and 5 volts equaling maximum

speed. The bias voltage of 0 and 5 volts for the potentiometer is provided by the speed controller from the

Pot-Lo and Pot-Hi outputs.

25% PWM Duty Cycle

50% PWM Duty Cycle

75% PWM Duty Cycle

100% PWM Duty Cycle

1-Cycle

(15kHz)

Loading...

Loading...