72Service Manual – SC900 40-Recovery System

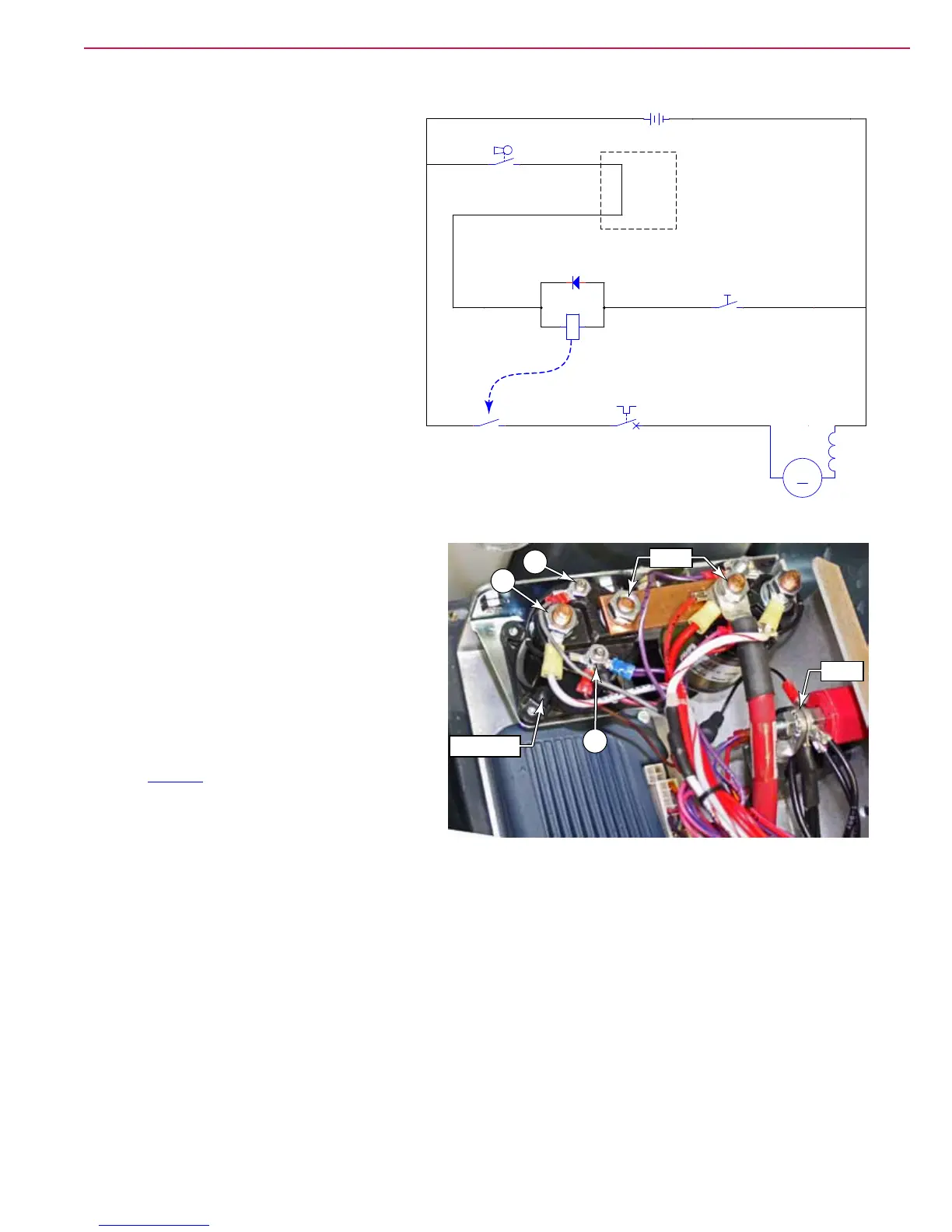

Circuit Overview

Unlike other machine functions, the vacuum

circuit is not dependant on the drive function

nor the low voltage cutout of the hour meter.

The only prerequisite for the vacuum circuit is

the main key switch.

The vacuum motor is controlled by the K3

relay, which in turn, is controlled by the

vacuum switch at the squeegee lift lever.

Troubleshooting

No Vacuum Motor

If the vacuum motor is not functioning, but

all other machine functions are unaffected,

The problem is limited to the vacuum switch,

relay, circuit breaker, and the motor itself. Begin troubleshooting at the K3 relay.

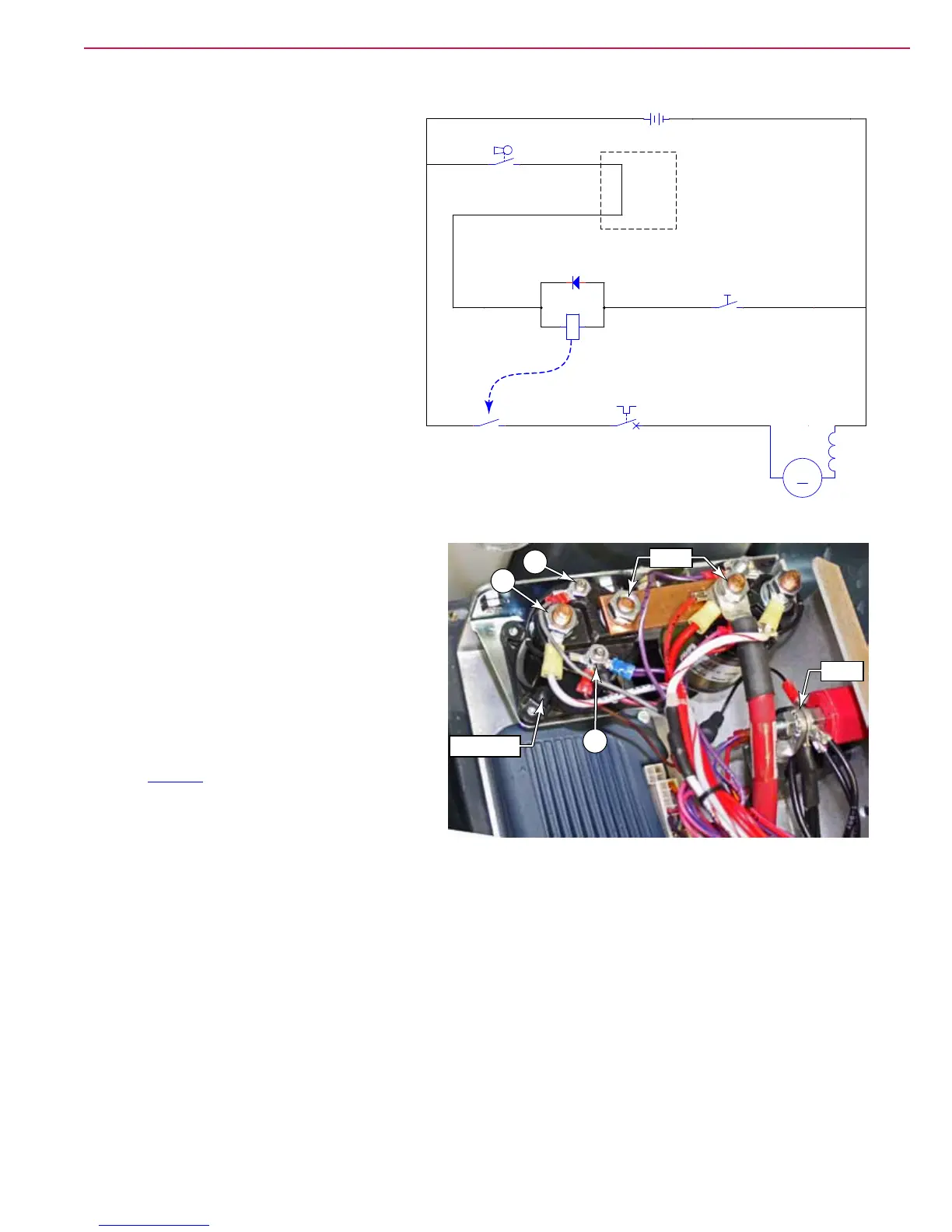

• Check the voltage from relay out (A) and

battery-negative (Batt-). If 36 volts is present,

then the problem is isolated to the circuit

breaker or motor itself.

– Check for 36 volts at both terminals of the

circuit breaker.

– Check for 36 volts at the vacuum motor

connector.

– If 36 volts is reaching the motor, then

inspect/replace the motor brushes described

on page 75.

• If 36 volts was not present at (A), then check

the voltage between (B) and (C). If 36 volts is

present, then the relay is defective.

• If 36 volts is not present between (B) and (C), then the vacuum switch is likely the cause.

Poor Suction

• Inspect the recovery tank cover seal. If the cover is not well sealed, the squeegee will have very low

vacuum.

• Inspect the vacuum motor inlet screen and clean any built-up debris from the screen.

• Inspect the squeegee and suction hose for obstructions or leaks.

• Replace the squeegee blades if they are nicked or torn.

• Make sure that the recovery tank drain hose cap seals airtight.

BLK

VIO

VIO/WHT

VIO

S1

SW, SPST KEY

S5

SW, VACUUM

D3

36 VDC

+ -

K3

COIL, VACUUM

GRA/RED ORN/VIO

M4

MOTOR, VACUUM

CB4

20A

K3

VACUUM CONTACT

M

TELEMATICS

JUMPER

B

Batt+

Batt-

A

C

K3 Relay

Loading...

Loading...