TRUE METRIX

®

PRO System Comprehensive Resource Guide (GDH-FAD Enzyme) Quality Control Testing 18

Quality Control Testing

• Use ONLY TRUE METRIX

®

Control Solution to

perform Control Tests.

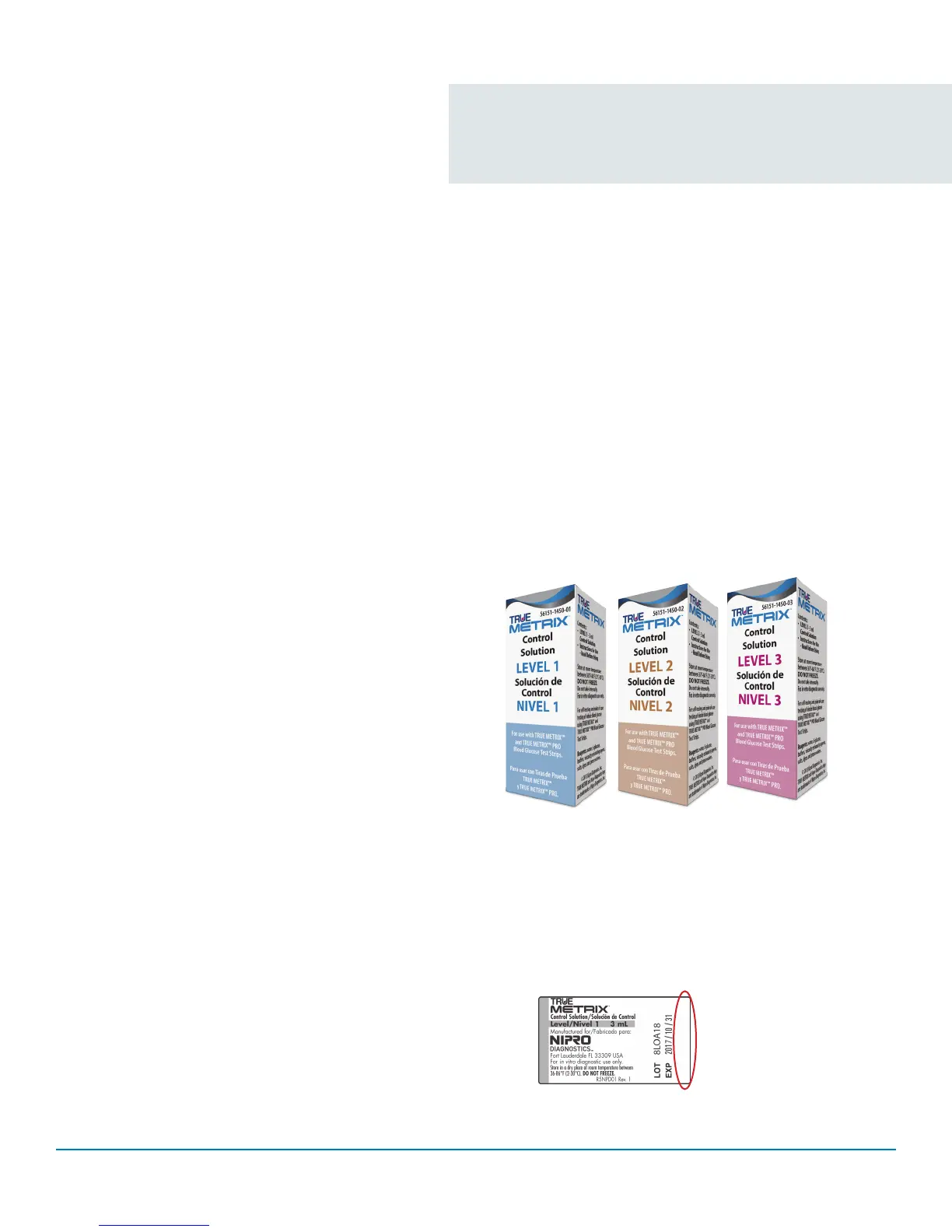

• Write date opened on control solution

label. Discard if either 3 months after first

opening or after the date printed next to

the EXP on the bottle label has passed,

whichever comes first.

• Control Test ranges are printed on the

TRUE METRIX

®

PRO Test Strip vial label.

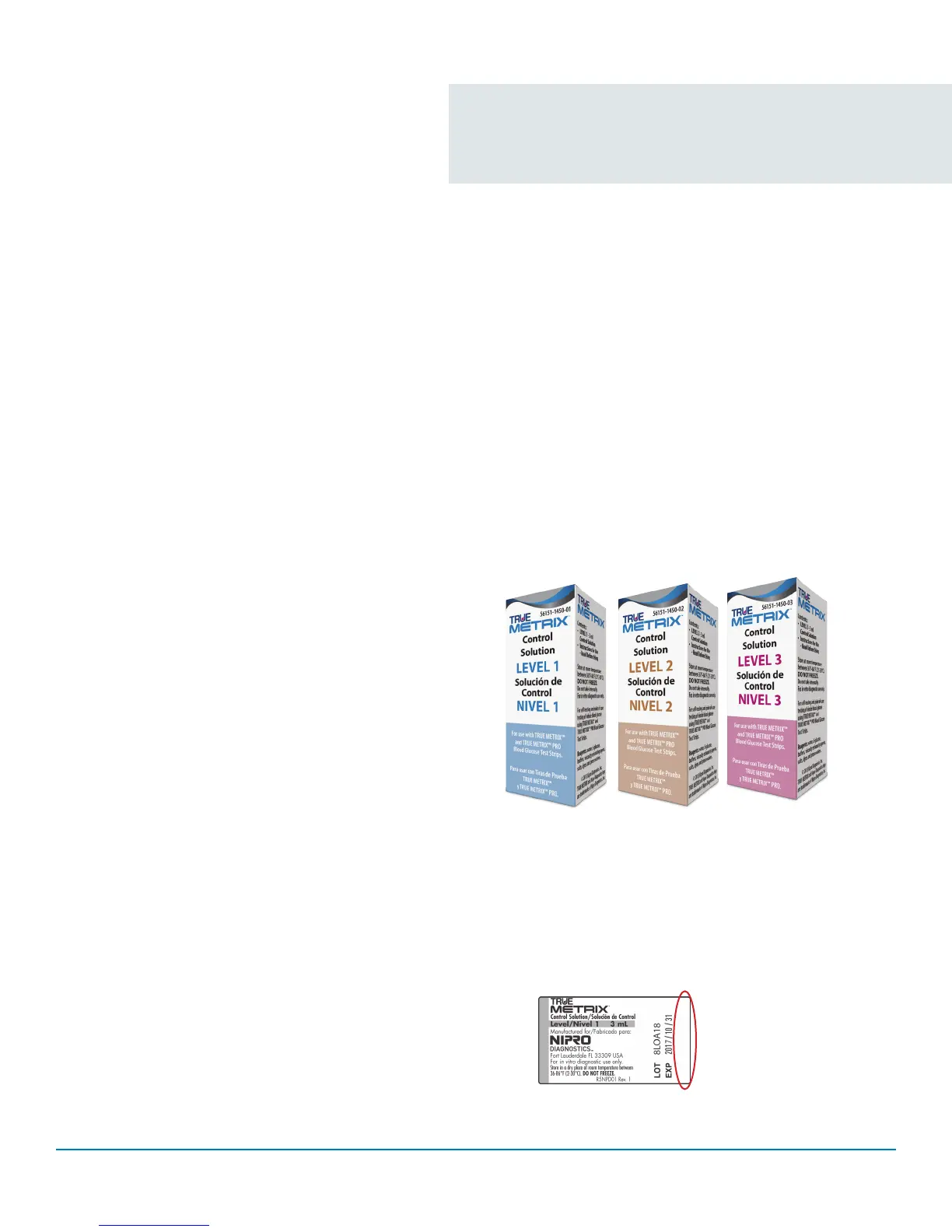

3 Levels of Control Solution

Quality Control Testing is used to detect errors that

may occur due to test system errors, product defects,

adverse environmental conditions and variance in

operator performance. Ongoing Quality Control Testing

is also used to detect any performance issues of the

system over time. Facility Quality Control Testing Policy

and Procedure should adhere to the manufacturer’s

instructions for use and regulatory guidelines.

TRUE METRIX

®

PRO is a no-coding system, which means

the meter does not have to be coded to each lot of test

strips. To assure accurate and reliable results, TRUE

METRIX

®

PRO offers two kinds of Quality Control Tests.

These tests ensure that the TRUE METRIX

®

PRO System

is working properly and the user’s testing technique

is good.

May 30, 2017

Loading...

Loading...