DRAFT

NOT FOR PUBLIC RELEASE

26

www.norcold.com/cda

N500/N510 Models

Refrigerator Service Manual

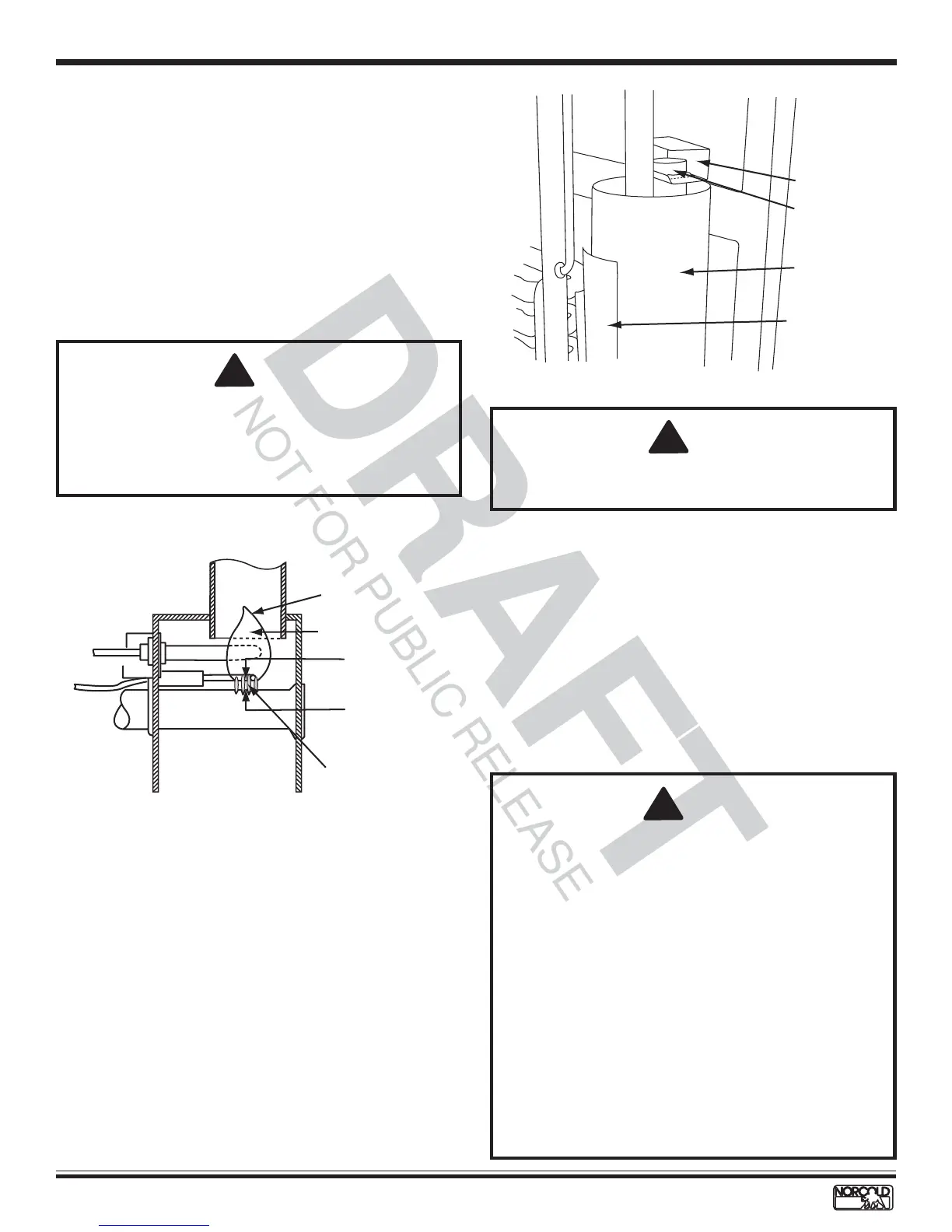

Figure 24. LP gas flame appearance.

Light blue outer mantle

Flame not touching

flue wall

Dark blue inner cones

3/16 in. electrode-

to-burner gap

Handling of LP Gas Lines and Fittings

Loosen and tighten all connections using two wrenches.

Insufficient or excessive force when tightening fittings

can result in loose joints or deformed joint parts. Either

condition can result in LP gas leakage.

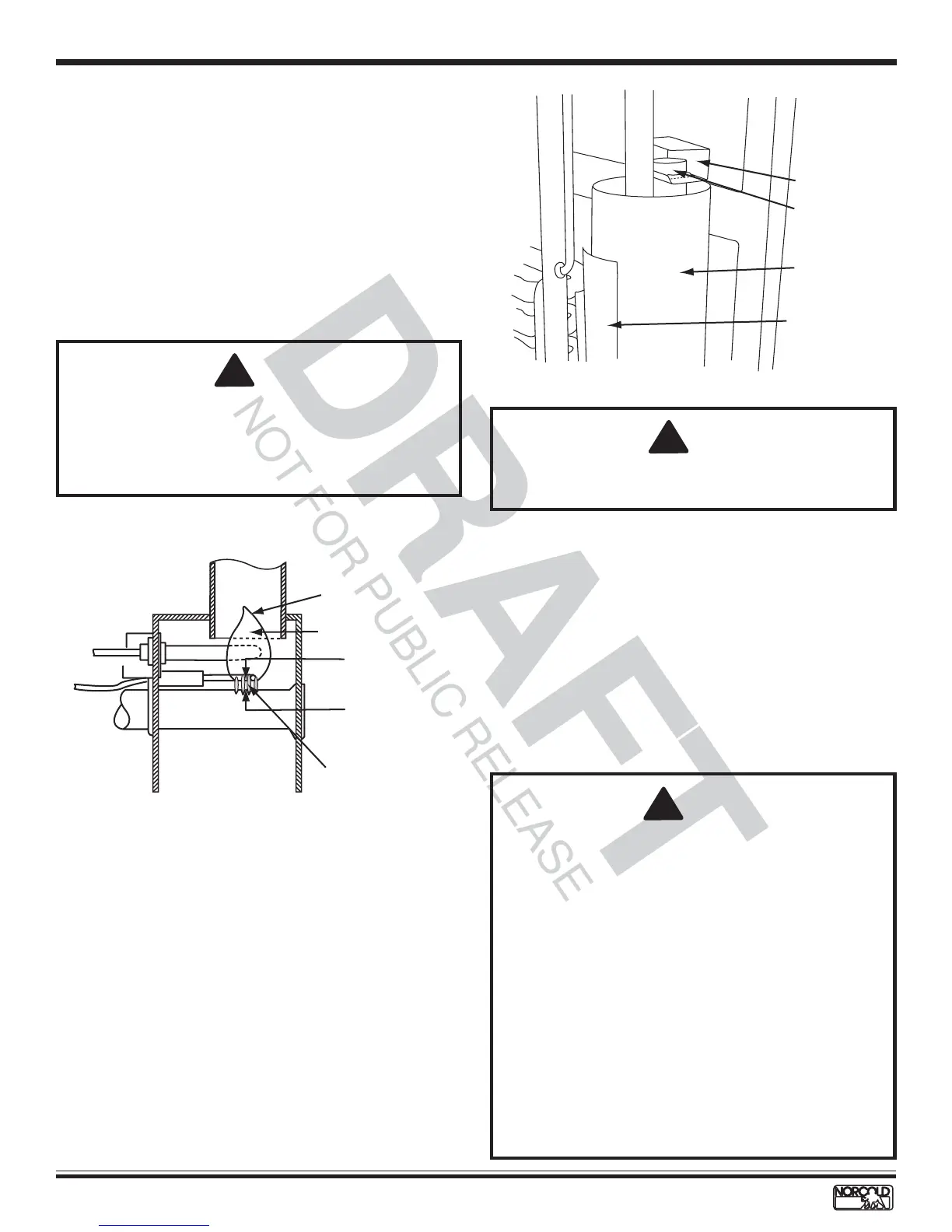

Figure 25. Flue and components

Canister

Flue cap

Flue tube

(flue baffle no

shown)

Canister door

Components Continued - All Models

Burner

A five slot burner is the combustion chamber for the LP

gas. Poor or no cooling while operating on LP gas can

usually be traced to a dirty, clogged, or damaged burner.

In most instances, a weak or erratic flame indicates the

burner and orifice need service. The burner flame

appearance should always conform to the pattern

shown in Figure 24. To check burner performance:

1. Set the thermostat knob to 5.

2. Start and operate the refrigerator on LP gas.

!

WARNING:

When working on or near the LP gas system:

T Do not smoke or light fires! Extinguish all open

flames!

T Do not use an open flame to leak test any of the

LP gas system components. LP gas is highly

flammable and explosive.

T Do not connect the refrigerator directly to the LP

gas tank. Always use an approved pressure

regulator between the LP gas tank and the

refrigerator LP gas system.

T Always use two wrenches to tighten or loosen

connections to prevent damage to connections,

piping, and components. Damaged connections,

piping, and components create the potential for gas

leaks.

LP GAS SYSTEM - ALL MODELS

!

CAUTION:

The burner box cover and inspection port cover may

be hot. To prevent burns, wear gloves and exercise

extreme care when working on the burner cover or

opening and closing the burner box inspection port

cover.

3. Open the burner box inspection port. Refer to Figure

24 for flame appearance guidelines.

Flue Tube

The flue tube channels hot exhaust gases towards the

exhaust vent. It should be cleaned annually to maintain

the combustion system at peak performance.

Flue Cap

The flue cap maintains a slight back pressure of hot

combustion exhaust gases in the flue tube. This slight

back pressure helps to establish and maintain a good

draft of ventilation air through the cooling unit.

Flue Baffle

The flue baffle is located inside the flue tube and helps

distribute the heat to the generator section of the

cooling unit. The flue baffle must never be permanently

removed. The flue baffle should be cleaned annually to

maintain the combustion system at peak performance.

To remove the flue baffle for cleaning:

1. Remove the flue cap (see Figure 25).

2. Unclip the baffle retaining wire from the rim of the flue

tube.

3. Pull the baffle out of the flue tube.

!

CAUTION:

Flue and components may be hot. Allow flue to cool

before servicing.

Loading...

Loading...