48

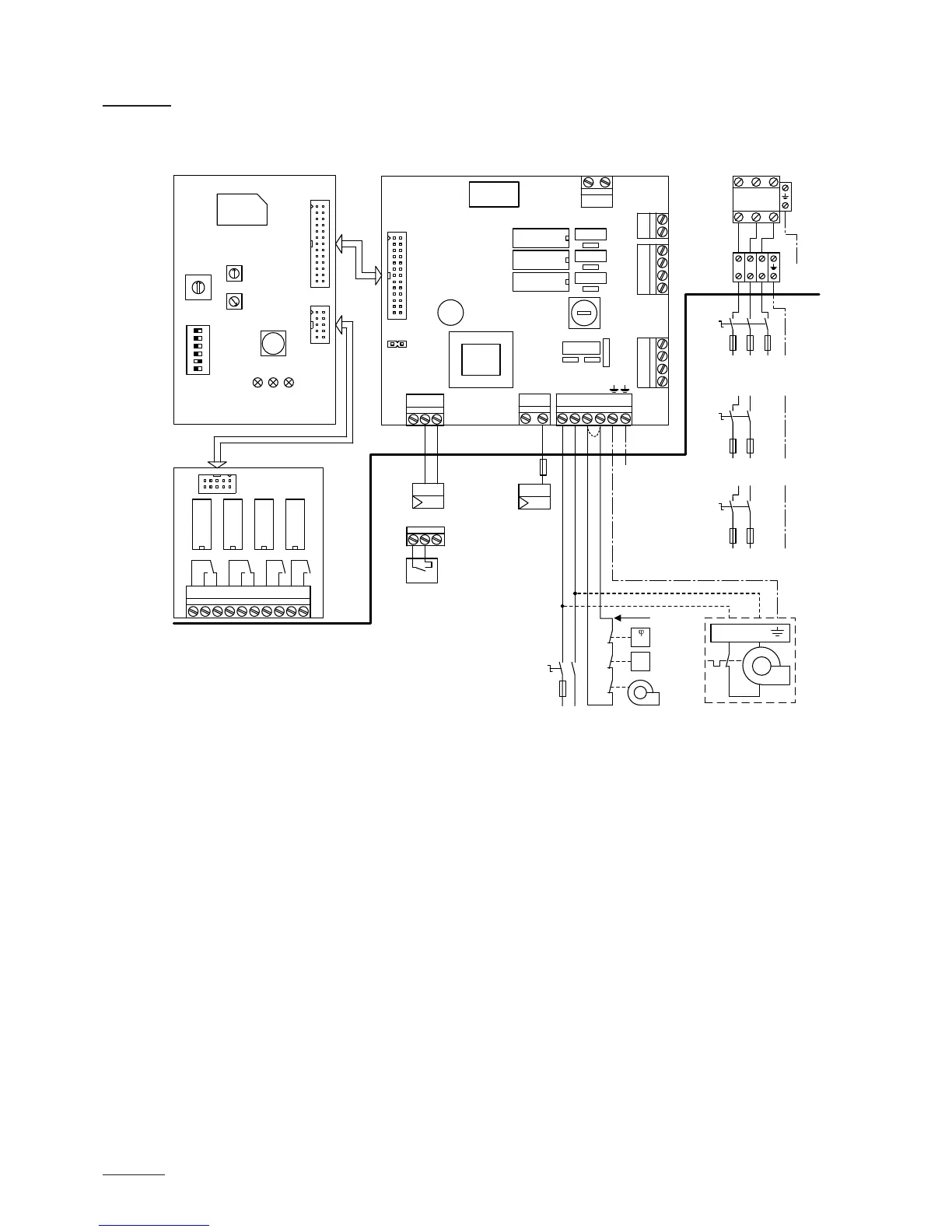

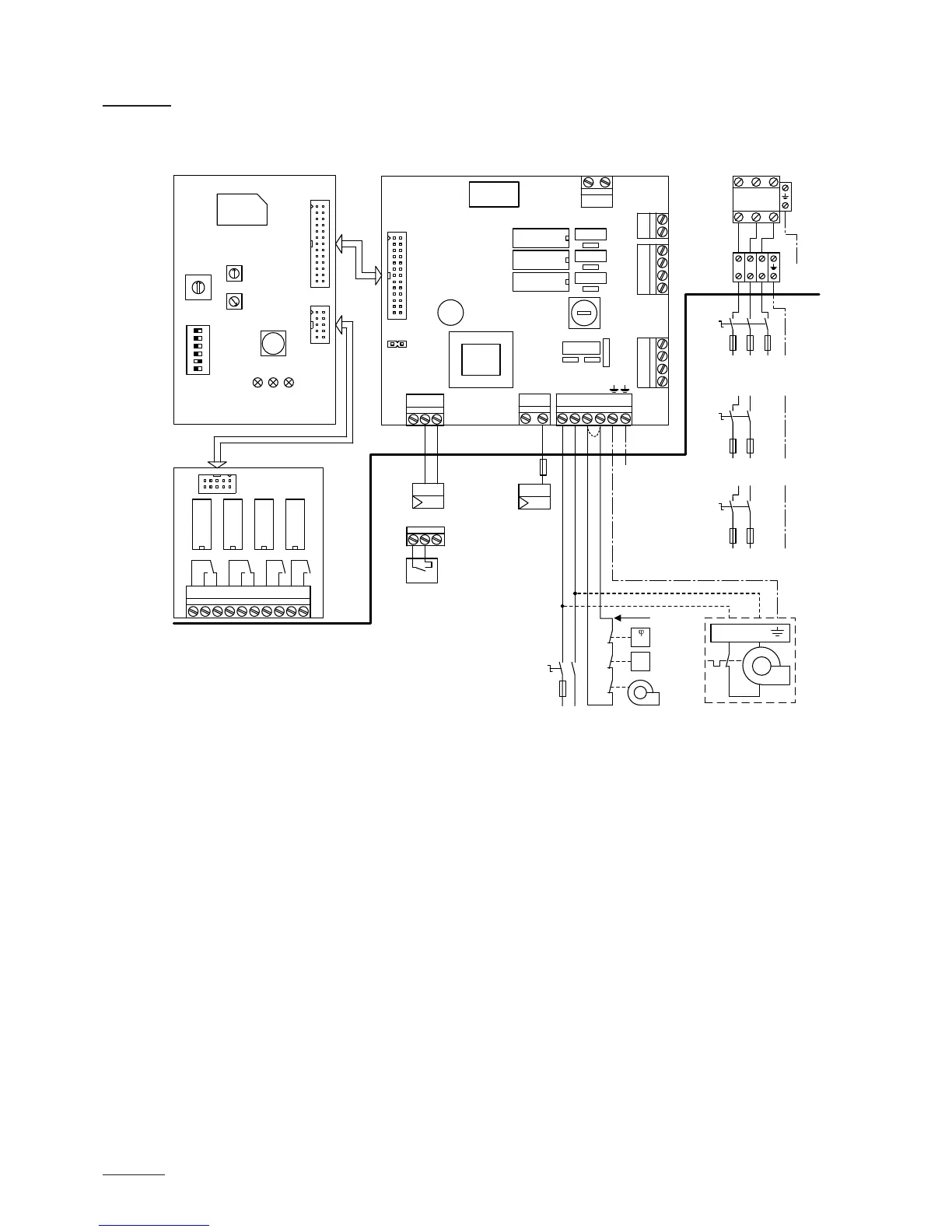

5.6 Electric installation

5.6.1 Wiring diagram Nordmann ES4

A1 Continuous controller (active 010V)

A2 On/Off controller (passive 24VDC), set jumper on JP1

A3 On/Off control (active 230VAC)

B1 Ventilation interlock

B2 Airow monitor

B3 Safety humidistat

F1 Internal fuse power board (6.3 A, slow acting)

F2 External fuse heating voltage supply

F3 External fuse control voltage supply

F4 External fuse 230V On/Off control

H1 Remote operating and fault indication (option “RFI”)

J Short circuited, if no external monitoring devices are connected

JP1 Jumper On/Off mode

K External safety chain (230V/5A)

K1 Main contactor (for connecting the heating voltage supply to the unit)

M Fan unit FAN4 N...

Q2 External service switch heating voltage supply

Q3 External service switch control voltage supply

S1 Rotary switch "Cylinder type”

S2 Potentiometer “Drain factor”

S3 Potentiometer “Power limitation”

S4 DIP switch “General unit settings”

X0 Connection terminal heating voltage (option THV)

X1 Connection terminal control signal

X2 Connection terminal On/Off control active

X3 Connection terminal control voltage

Control board Power board

ES4 Card

red yellow green

F1

(6.3 AT)

CONT.SIGN

V+ IN GND

X2 X3

VD

MAIN SUPPLY

L1 N SC1SC2

LEV.SENSOR

Driver board

CPU board

J1

X1

CURRENT SENSOR

CPU BOARD

1 2

On/Off

JP1 must be plugged

B3

K

B2

B1

J

Q3

230 V/1~/50..60 Hz

L1 N

F3

On/Off Mode

JP1

+ –

0-10V

A1

H1

A2

A3

F4

230V

L1’

1 2 3 4 5 6 7 8 9 10

Error Service Steam Unit On

Cylinder

Drain Factor

Power Limit

Manual Drain

Low Conduct.

Standby Drain

Force Drain

Cylinder A/D

GFCI-Mode

Offset

Settings

0

DriverRFI

ON

1 2 3 4 5 6

J8

J1

V+ IN GND

X5

X7

X8

X4

1 2 3 4

SWITCH

1 2 3 4

INLET

1 2

CONTACTORDRAIN

∆p

max.

M

L1 N

PE

S1

S2

S3

S4

L1

Q2

K1

X0

F2

L1 L2 L3

L1 L2 L3

L1 L2 L3

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q2

F2

L1 N PE

PE

PE

230 V/1~/50..60 Hz

Q2

F2

L1 L2

400 V/2~/50..60 Hz

PE

ES4

ext.

Loading...

Loading...