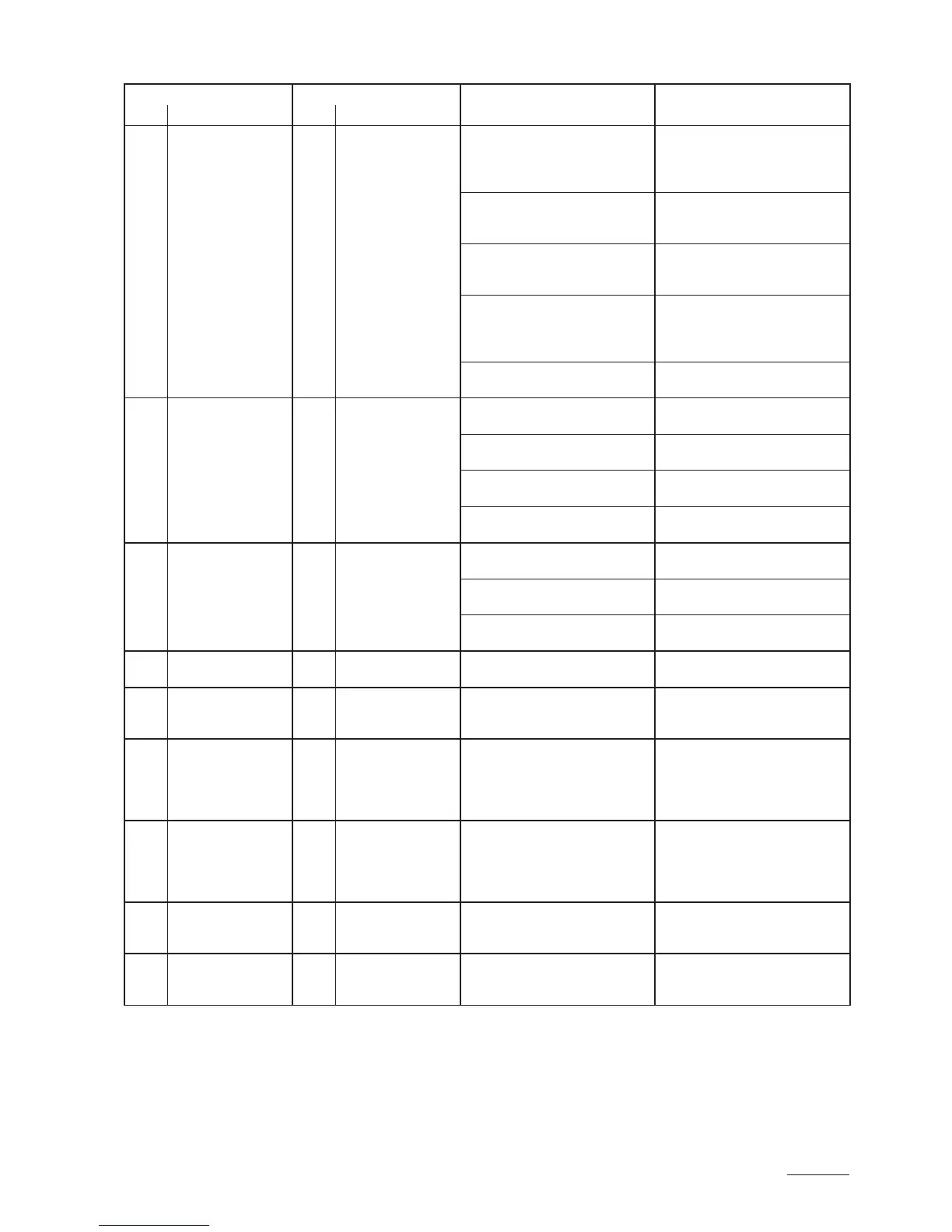

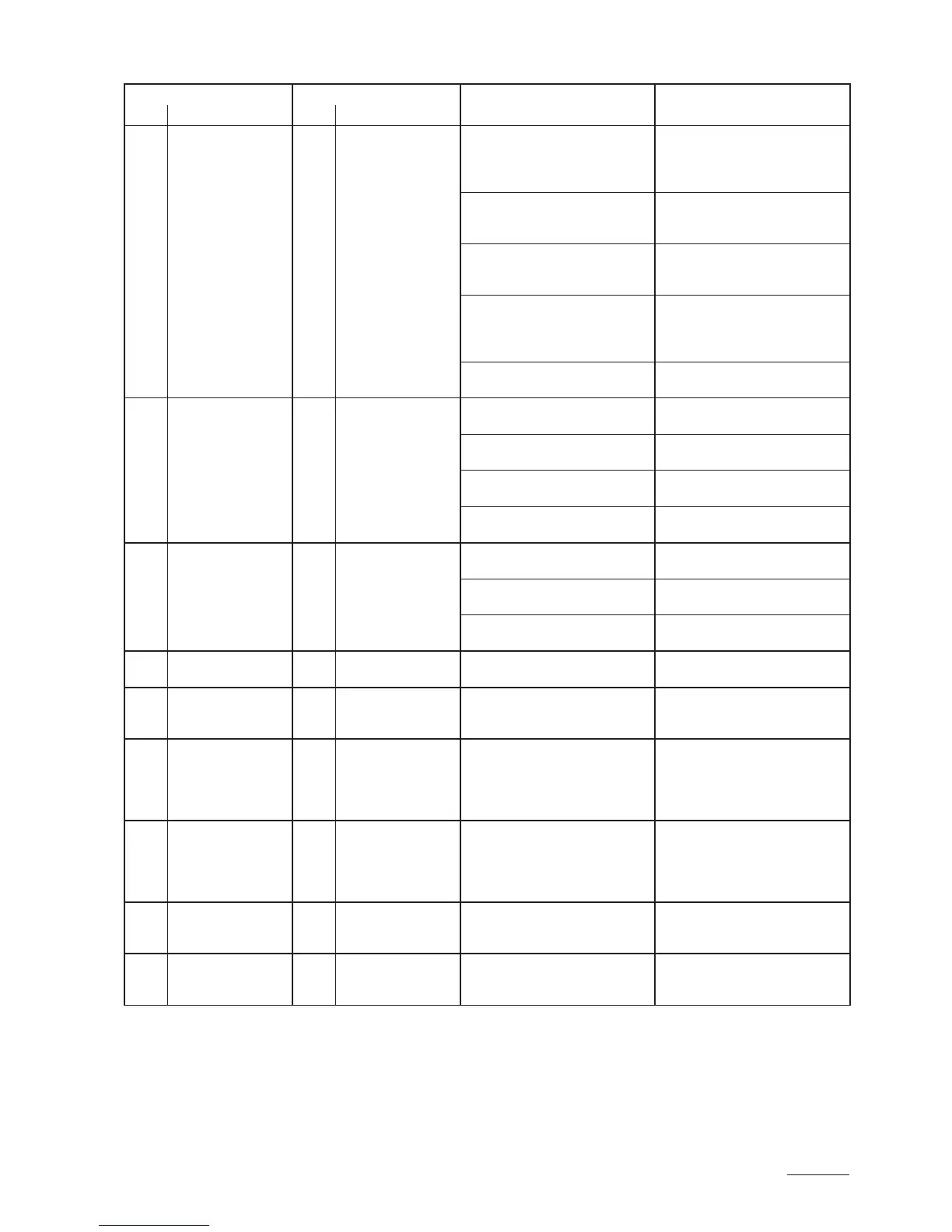

71

Warning Error Cause Remedy

Code Malfunction Code Malfunction

W23 No electrode current

for more than 20

minutes

E23 No electrode cur-

rent for more than

4 hours

Phase failure heating voltage. Inspect/turn on service switch of

the mains supply line. Inspect the

fuses of the mains supply, replace

if necessary.

Water supply obstructed/shutoff valve

closed/water pressure too low.

Inspect water supply (lter, water pip-

ing, etc.), check/open shutoff valve,

check water pressure.

Inlet valve blocked or defective. Inspect strainer insert of the inlet

valve, if applicable clean strainer

insert or replace inlet valve.

Excessive back pressure in the steam

line (duct pressure too high, steam

line too long or kinked), causing water

loss via lling cup.

Check duct pressure, inspect steam in-

stallation. If applicable install pressure

compensation kit (see options).

Leakage in the water system. Inspect water system and seal if

necessary.

W24 Electrode current in

relation to the steam

demand too high

E24 Electrode current in

relation to the steam

demand too high

Humidity demand has decreased too

fast.

Automatic adaptation of the operat-

ing point.

Drain valve defective. Inspect drain valve, replace if nec-

essary.

Drain screen in the drain outlet of the

steam cylinder clogged.

Clean drain screen (see chapter 7.3.2

and 7.4) or replace steam cylinder.

Water conductivity too high for this

type of steam cylinder.

Select correct steam cylinder type.

W25 Max. admissible

electrode

current exceeded

E25 Max. admissible

electrode

current exceeded

Drain valve defective. Inspect drain valve, replace if nec-

essary.

Drain screen in the drain outlet of the

steam cylinder clogged.

Clean drain screen (see chapter 7.3.2

and 7.4) or replace steam cylinder.

Water conductivity too high for this

type of steam cylinder.

Select correct steam cylinder type.

––– ––– E26 Main contactor

jammed

Main contactor jammed in activated

position.

Inspect main contactor, replace if

necessary.

W27 Foam detection E27 Foam detection (4

automatic drainings

within 24 hours)

Foaming in steam cylinder. Drain steam cylinder via drain key

(several times, if necessary). Check

quality of the supply water.

W28 Steam cylinder

needs service

E28 Service interval for

steam cylinder

exceeded

Mineral deposits and/or electrodes

spent.

Replace steam cylinder.

Important: After the replacement of

the steam cylinder, reset the main-

tenance counter (see chapter 7.6).

W29 Steam cylinder

needs service

E29 Max. operating

hours of the steam

cylinder reached

Maximum operating hours of the

steam cylinder reached.

Replace steam cylinder.

Important: After the replacement of

the steam cylinder, reset the main-

tenance counter (see chapter 7.6).

W36 Standby draining of

steam cylinder

active

––– ––– Automatic standby draining of

steam cylinder active.

No measures must be taken.

W37 Forced draining of

steam cylinder

active

––– ––– Forced draining of steam cylinder

active.

No measures must be taken.

Loading...

Loading...