START-UP OPERATION

HAMMERS THAT ARE NEW, REBUILT, OR

HAVE BEEN INACTIVE

Before using a new hammer for the first time, the first time after rebuild, or a

hammer that has been inactive for a long period of time:

1. Check the nitrogen gas pressure.

The nitrogen gas pre-charge is factory checked before shipment. However, it is

recommended the pressure be checked before using the NPK HYDRAULIC

HAMMER for the first time. For the inspection procedure, see CHECKING THE

GAS PRESSURE, page 64.

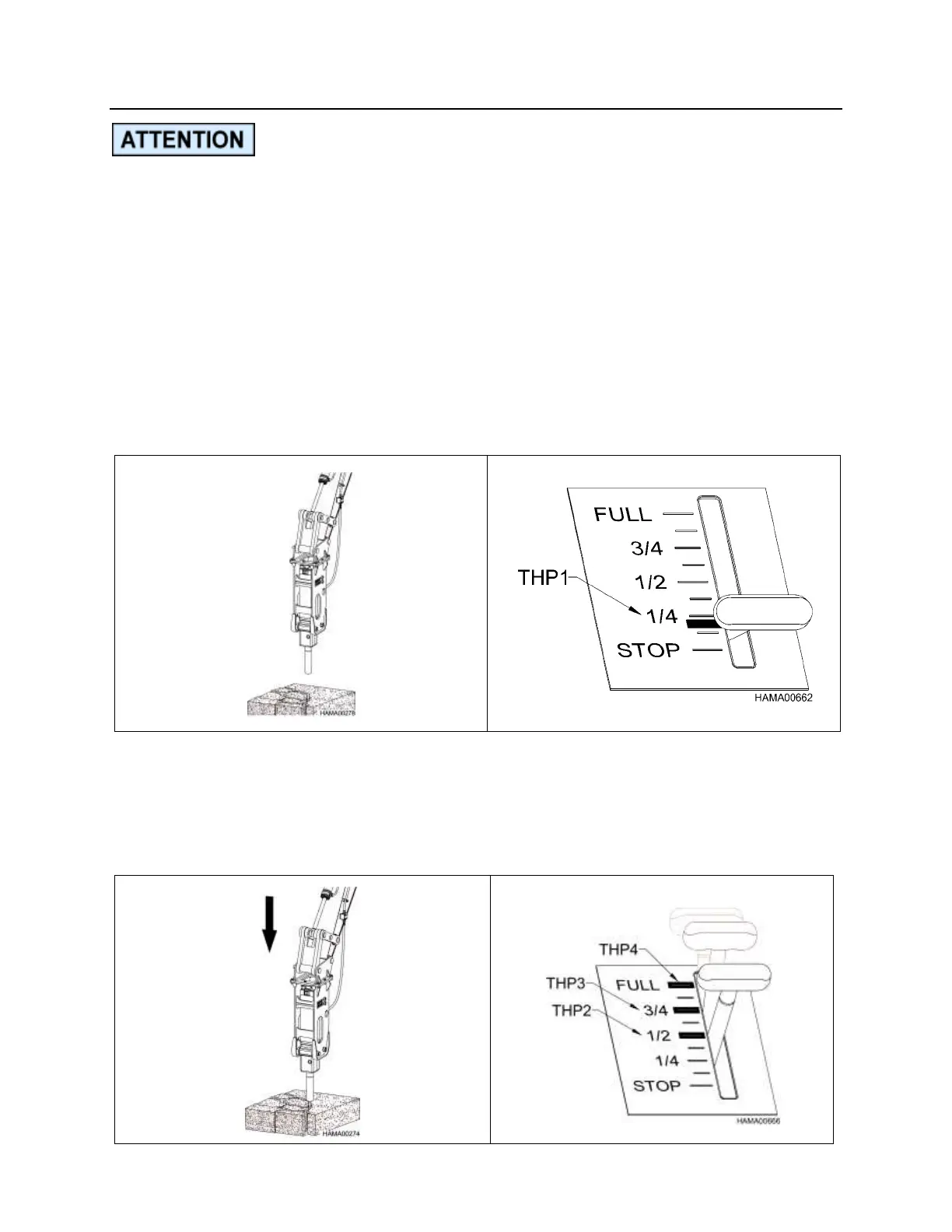

2. At idle (THP1), raise the hammer off the ground. Place hammer vertical and

activate the hammer hydraulic circuit for 3 – 5 second intervals. Continue for an

additional 3 – 4 times to ensure that all the air has been purged from the hoses and

the hammer before first use. Failure to do this could result in damage to the

hammer’s internal components.

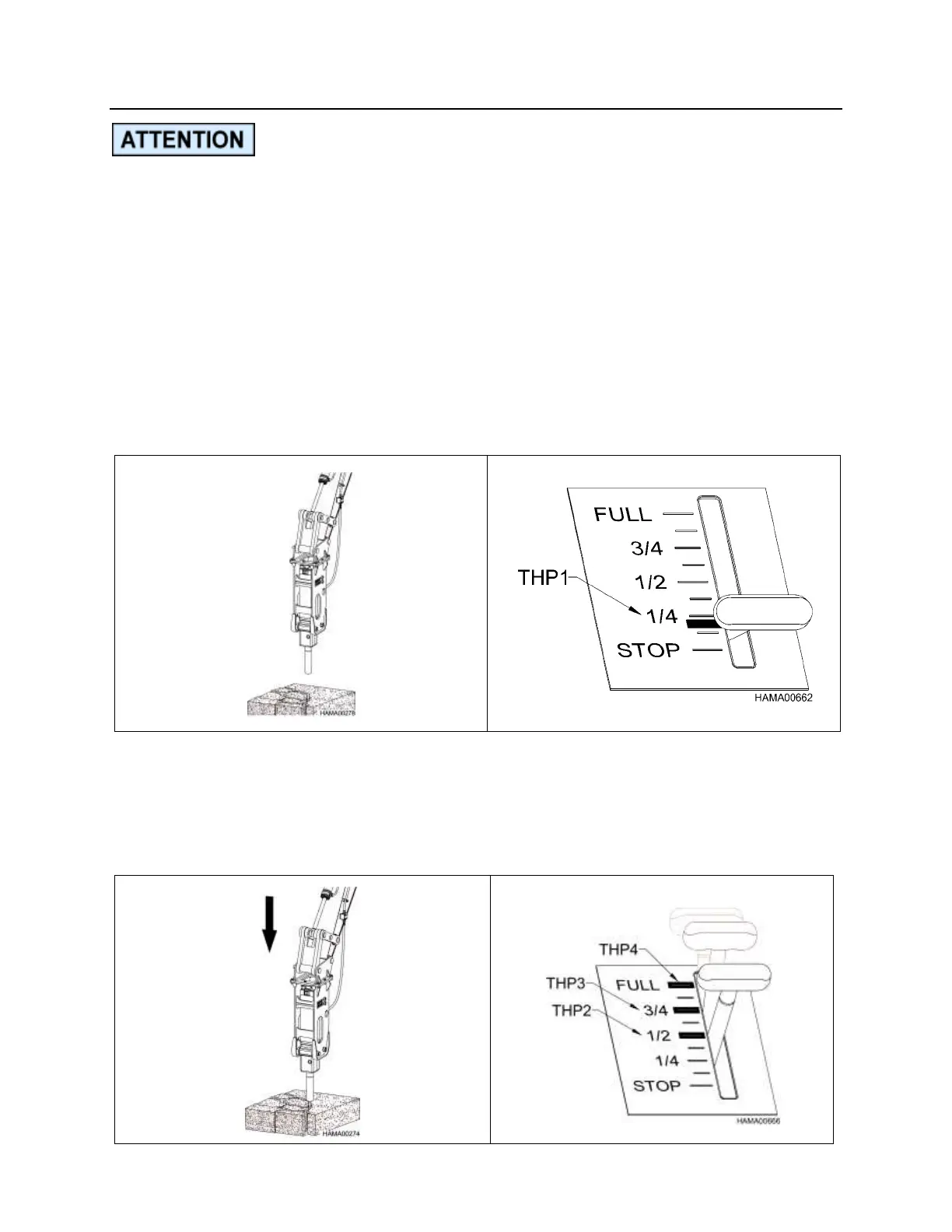

3. Place hammer firmly against the material to be broken (see “PRELOAD THE

TOOL BEFORE STARTING”). Operate the hammer in a vertical position for

approximately 10 minutes at one-half (THP2) engine speed. Increase engine speed

to three-quarters (THP3) and continue operating at this speed for another 10 to 20

minutes. Increase to full engine speed (THP4). Maintain vertical position for the

duration of the operation.

Loading...

Loading...