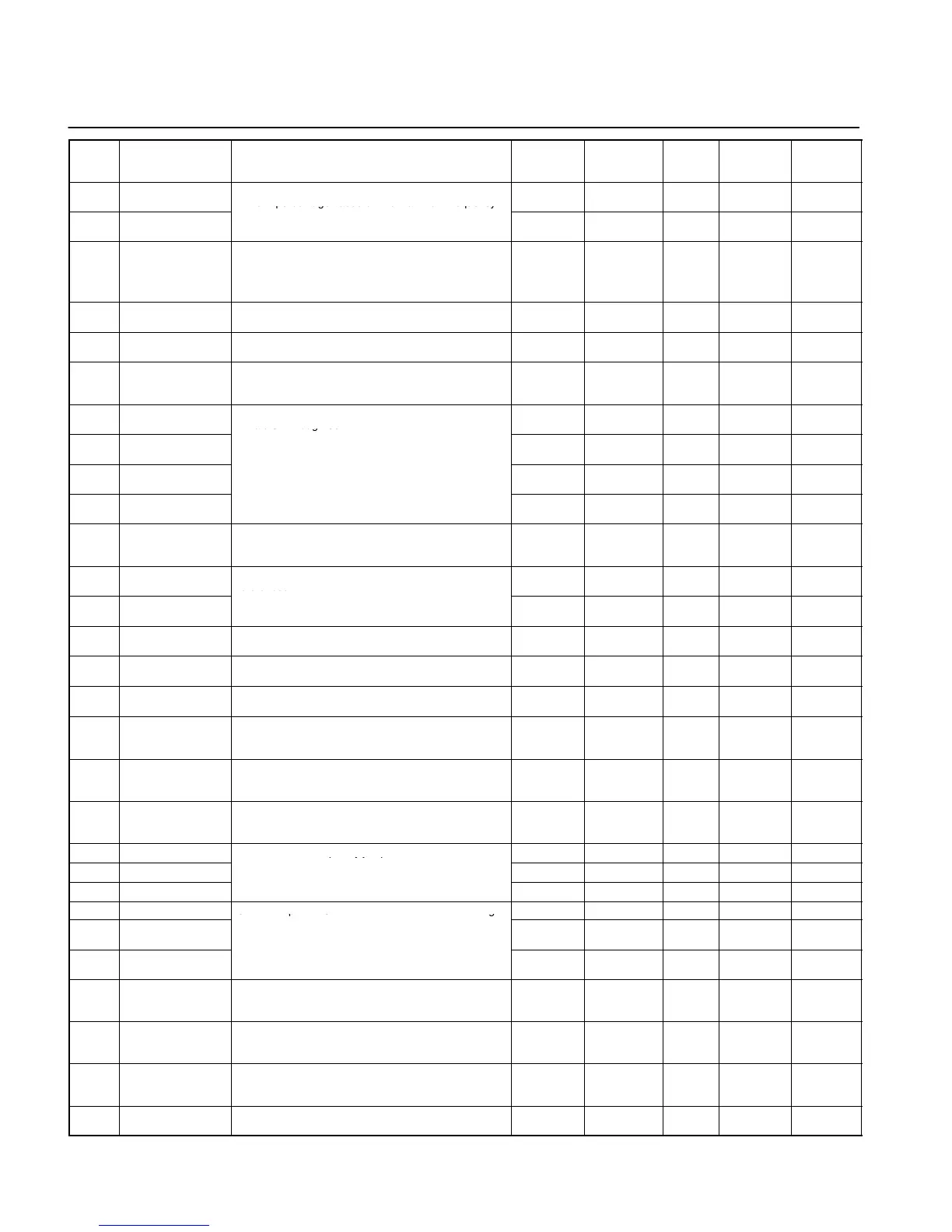

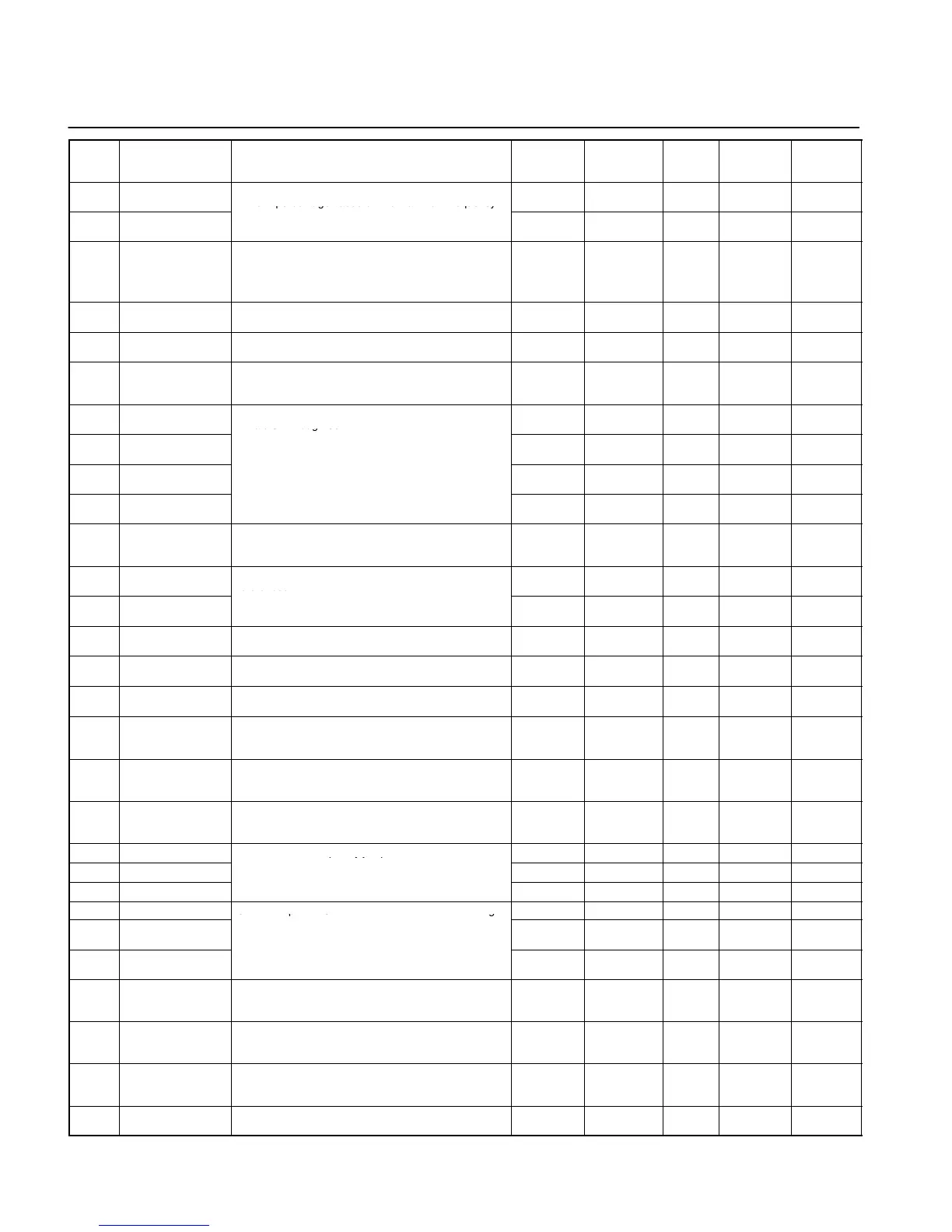

List of Parameters

12

Param-

eter

No.

Name Description Setting

range

Unit of

setting

(see note)

Default

setting

Changes

during op-

eration

Reference

page

n30 Frequency reference

upper limit

Used to set the upper and lower frequency reference

limits in percentage based on the maximum frequency

0 to 110 1% 100 No 16

n31 Frequency reference

lower limit

as 100%.

0 to 110 1% 0 No 16

n32 Rated motor current Used to set the rated motor current for motor overload

detection (OL1) based on the rated motor current.

Note Motor overload detection (OL1) is disabled by set-

ting the parameter to 0.0.

0.0 to 120%

of rated out-

put current

0.1 A Varies

with the

capacity.

No 16

n33 Motor protection

characteristics

Used to set the motor overload detection (OL1) for the

electronic thermal characteristics of the motor.

0 to 2 1 0 No 16

n34 Motor protective

time setting

Used to set the electric thermal characteristics of the

motor to be connected in 1-minute increments.

1 to 60 1 min 8 No 16

n35 Cooling fan opera-

tion function

Used to operate the Cooling Fan of the Inverter while

the Inverter is turned on or only while the Inverter is in

operation.

0, 1 1 0 No 16

n36 Multi-function input 1

(Input terminal S2)

Used to select the functions of multi-function input ter-

minals S2 through S5.

2 to 22 1 2 No 16

n37 Multi-function input 2

(Input terminal S3)

0 to 22 1 5 No 16

n38 Multi-function input 3

(Input terminal S4)

2 to 22 1 3 No 16

n39 Multi-function input 4 2 to 34 1 6 No 16

n40 Multi-function output

(MA/MB and MC

output terminals)

Used to select the functions of multi-function output

terminals.

0 to 7, 10 to

17

1 1 No 17

n41 Frequency reference

gain

Used to the input characteristics of analog frequency

references.

0 to 255 1% 100 Ye s 17

n42 Frequency reference

bias

–99 to 99 1% 0 Yes 17

n43 Analog frequency

reference filter time

Used to set the digital filter with a first-order lag for ana-

log frequency references to be input.

0.00 to 2.00 0.01 s 0.10 No 17

n44 Analog monitor

output

Used to set the output frequency or current as a moni-

tored item.

0, 1 1 0 No 17

n45 Analog monitor

output gain

Used to set the output characteristics of analog monitor

output.

0.00 to 2.00 0.01 1.00 Ye s 17

n46 Carrier frequency

selection

Used to set the carrier frequency. 1 to 4, 7 to

9

1 Varies

with the

capacity.

No 18

n47 Momentary power

interruption com-

pensation

Used to specify the processing that is performed when

a momentary power interruption occurs.

0 to 2 1 0 No 18

n48 Fault retry Used to set the number of times the Inverter is reset

and restarted automatically in the case the Inverter has

an overvoltage fault, overcurrent fault, or ground fault.

0 to 10 1 0 No 18

n49 Jump frequency 1

Used to set the frequency jump function.

0.0 to 400 0.1 Hz 0.0 No 18

n50 Jump frequency 2

qyjp

Note These values must satisfy the following condi

-

0.0 to 400 0.1 Hz 0.0 No 18

n51 Jump width

-

tion: n49 y n50

0.0 to 400 0.1 Hz 0.0 No 18

n52 DC control current

Used to impose DC on the induction motor for braking

0 to 100 1% 50 No 18

n53 Interruption DC

control time

control.

0.0 to 25.5 0.1 s 0.5 No 18

n54 Startup DC control

time

0.0 to 25.5 0.1 s 0.0 No 18

n55 Stall prevention

during deceleration

Used to select a function to change the deceleration

time of the motor automatically so that there will be no

overvoltage imposed on the motor during deceleration.

0, 1 1 0 No 18

n56 Stall prevention level

during acceleration

Used to select a function to stop the acceleration of the

motor automatically for stall prevention during

acceleration.

30 to 200 1% 170 No 19

n57 Stall prevention level

during operation

Used to select a function to reduce the output

frequency of the Inverter automatically for stall

prevention during operation.

30 to 200 1% 160 No 19

n58 Frequency detection

level

Used to set the frequency to be detected. 0.0 to 400 0.1 Hz 0.0 No 19

Note: Values longer than 3 digits are rounded up to the next unit multiple.

Loading...

Loading...