60

Using ON/OFF Control Section 3-7

3-7 Using ON/OFF Control

In ON/OFF control, the control output turns OFF when the temperature being

controlled reaches the preset set point. When the manipulated variable turns

OFF, the temperature begins to fall and the control turns ON again. This oper-

ation is repeated over a certain temperature range. At this time, how much the

temperature must fall before control turns ON again is determined by the Hys-

teresis (Heating) parameter. Also, what direction the manipulated variable

must be adjusted in response to an increase or decrease in the process value

is determined by the Direct/Reverse Operation parameter.

3-7-1 ON/OFF Control

• Switching between 2-PID control and ON/OFF control is performed using

the PID ON/OFF parameter in the initial setting level. When this parame-

ter is set to pid, 2-PID control is selected, and when it is set to onof, ON/

OFF control is selected. The default is onof.

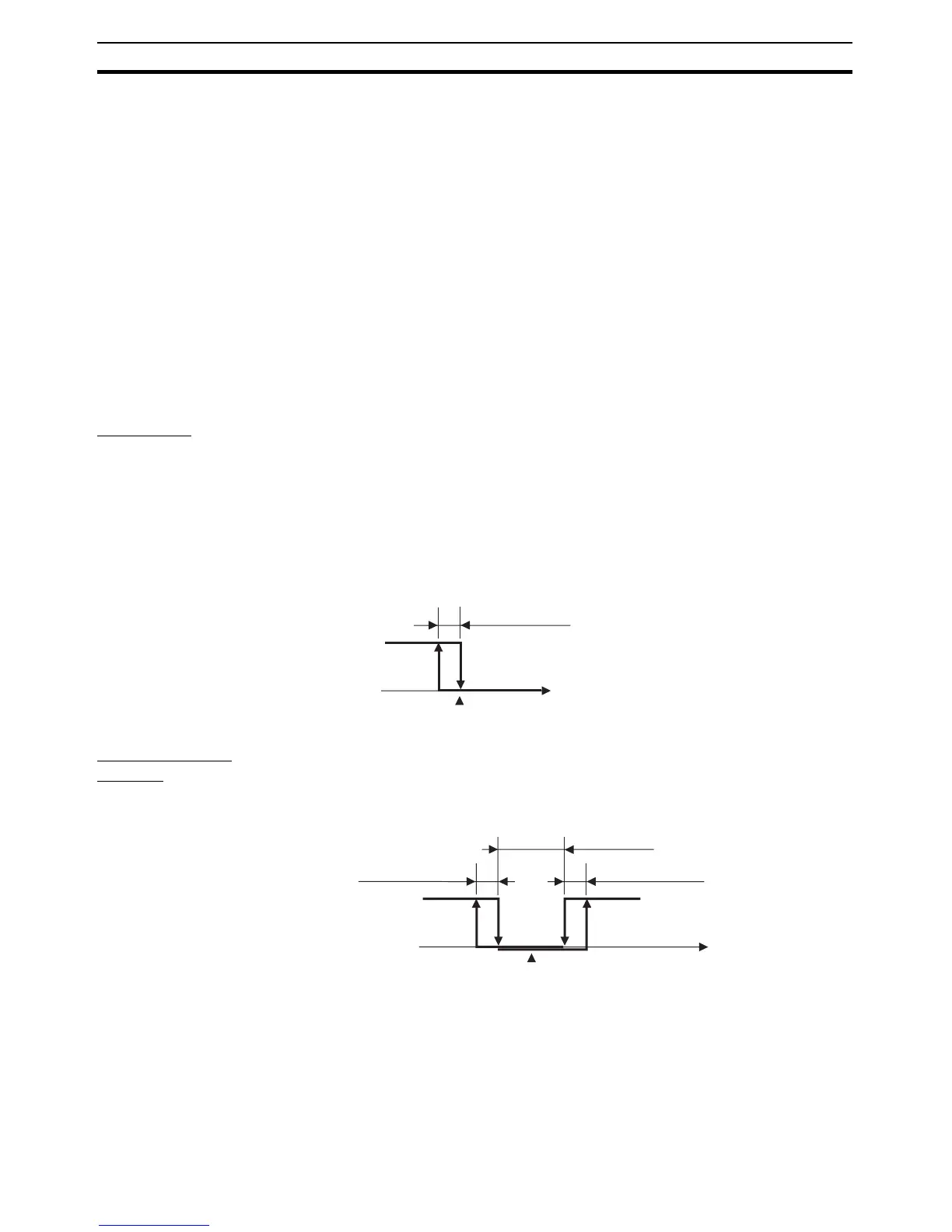

Hysteresis • With ON/OFF control, hysteresis is used to stabilize operation when

switching between ON and OFF. The control output (heating) and control

output (cooling) functions are set in the Hysteresis (Heating) and Hystere-

sis (Cooling) parameters, respectively.

• In standard control (heating or cooling control), the setting of the Hystere-

sis (Heating) parameter in the adjustment level is used as the hysteresis

regardless of whether the control type is heating control or cooling con-

trol.

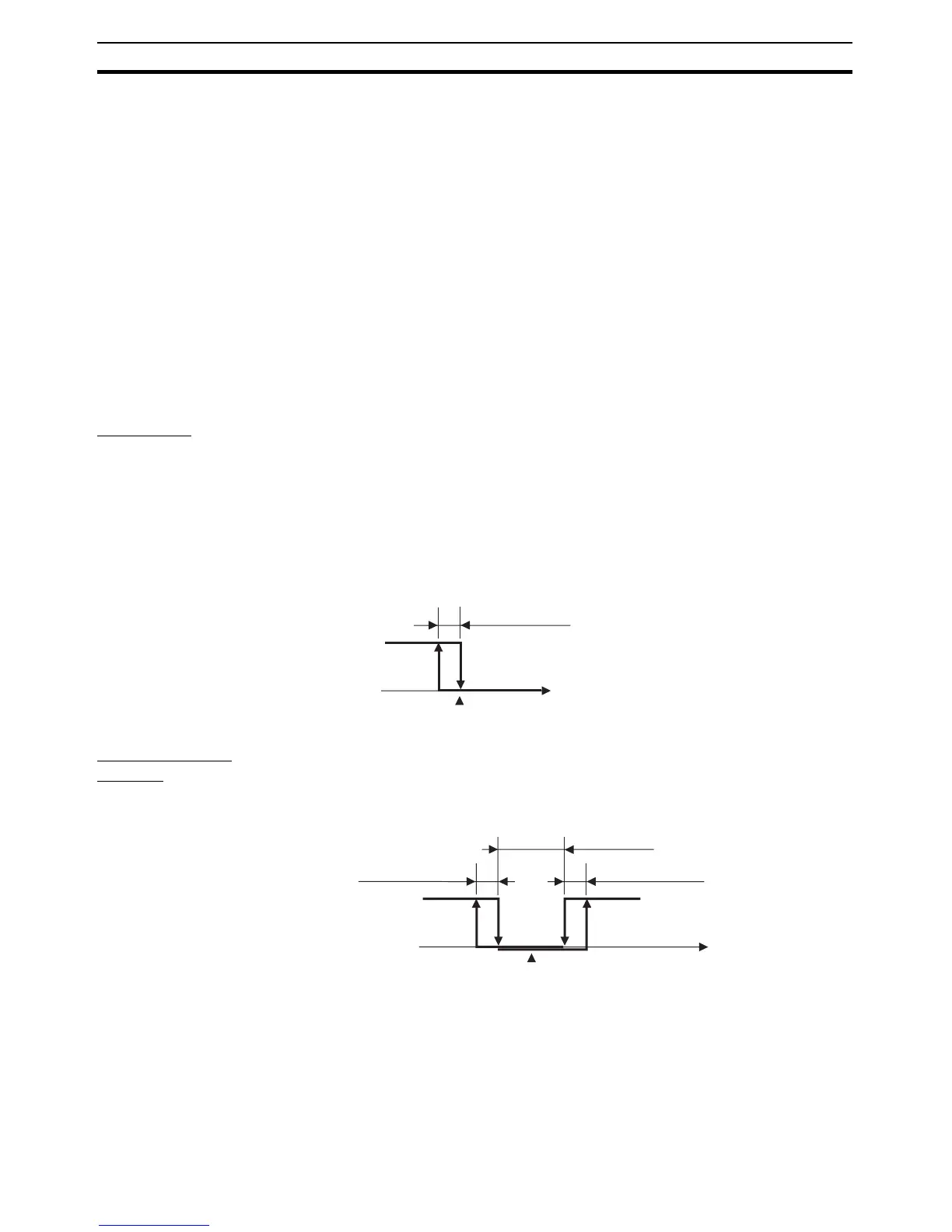

Three-position

Control

• In heating/cooling control, a dead band (an area where both control out-

puts are 0) can be set to either the heating or cooling side. This makes it

possible to use 3-position control.

PV

ON

OFF

Reverse operation

Hysteresis (heating)

Set

Loading...

Loading...