4-105

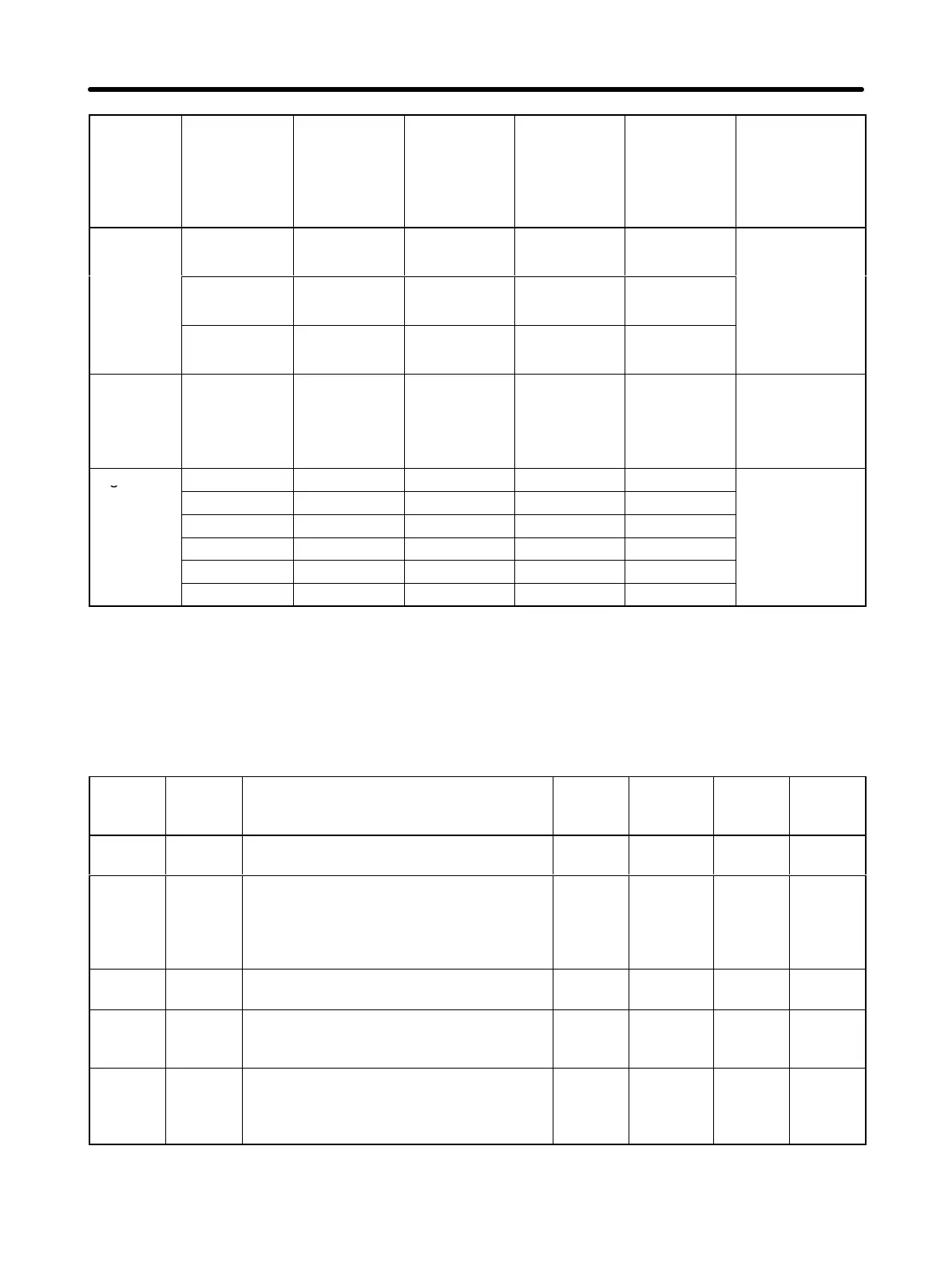

Response Rigidity

setting

Fn001

(d.00jj)

Position

loop gain

(S

–1

)

Pn102

Speed loop

gain

(Hz)

Pn100

Speed loop

integration

time

constant

(x 0.01 ms)

Pn101

Torque

command

filter time

constant

(x 0.01 ms)

Pn401

Representative

applications

(mechanical

system)

Low

01 15 15 6000 250

Articulated

robots,

02 20 20 4500 200

drives, chain

drives, belt

03 30 30 3000 130

drives, rack and

pinion drives,

etc.

Medium 04 40 40 2000 100 XY tables, Car-

tesian-coordi-

nate robots,

general-purpose

machinery, etc.

High

05 60 60 1500 70

Ball screws

06 85 85 1000 50

(direct

07 120 120 800 30

coup

ng

,

08 160 160 600 20

,

.

09 200 200 500 15

10 250 250 400 10

Note 1. The servo-system loop gain will rise in response to a higher rigidity setting, shortening posi-

tioning time. If the setting is too large, however, the machinery may vibrate, so make the set-

ting small.

Note 2. When the rigidity is set, the user parameters in the above table will change automatically.

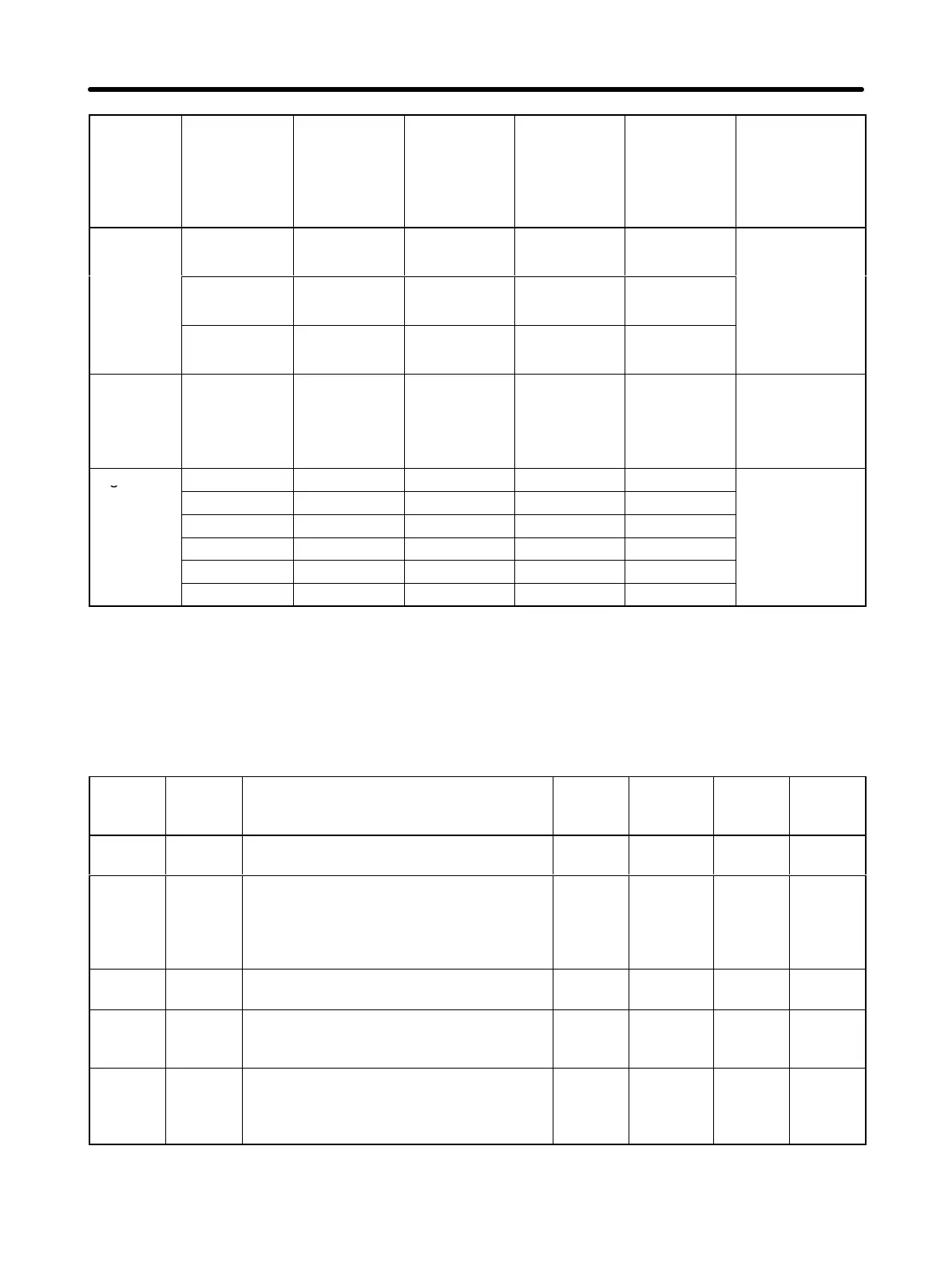

H Manual Tuning-related User Parameters

Parame-

ter No.

Parame-

ter

name

Explanation Default

setting

Unit Setting

range

Restart

power?

Pn100 Speed

loop gain

Adjusts speed loop responsiveness. 80 Hz 1 to

2000

No

Pn101 Speed

loop

integrati

on time

constant

Speed loop integration time constant 2000 x 0.01 ms 15 to

51200

No

Pn102 Position

loop gain

Adjusts position loop responsiveness. 40 1/s 1 to

2000

No

Pn103 Inertia

ratio

Sets the ratio using the mechanical

system inertia to Servomotor rotor inertia

ratio.

300 % 0 to

1000

No

Pn401 Torque

command

filter time

constant

Sets the filter time constant for the

internal torque command.

40 x 0.01 ms 0 to

65535

No

Note Refer to 4-4-4 Parameter Details for details of each parameter.

Operation Chapter 4

Loading...

Loading...