4-112

Note 2. A torque will be generated that accelerates the Servomotor in the forward direction if torque

feed-forward is applied with a positive (+) voltage. Be sure that the polarity is correct because

errors such as reverse Servomotor rotation or oscillation will occur if the feed-forward is ap-

plied with a polarity opposing the acceleration direction.

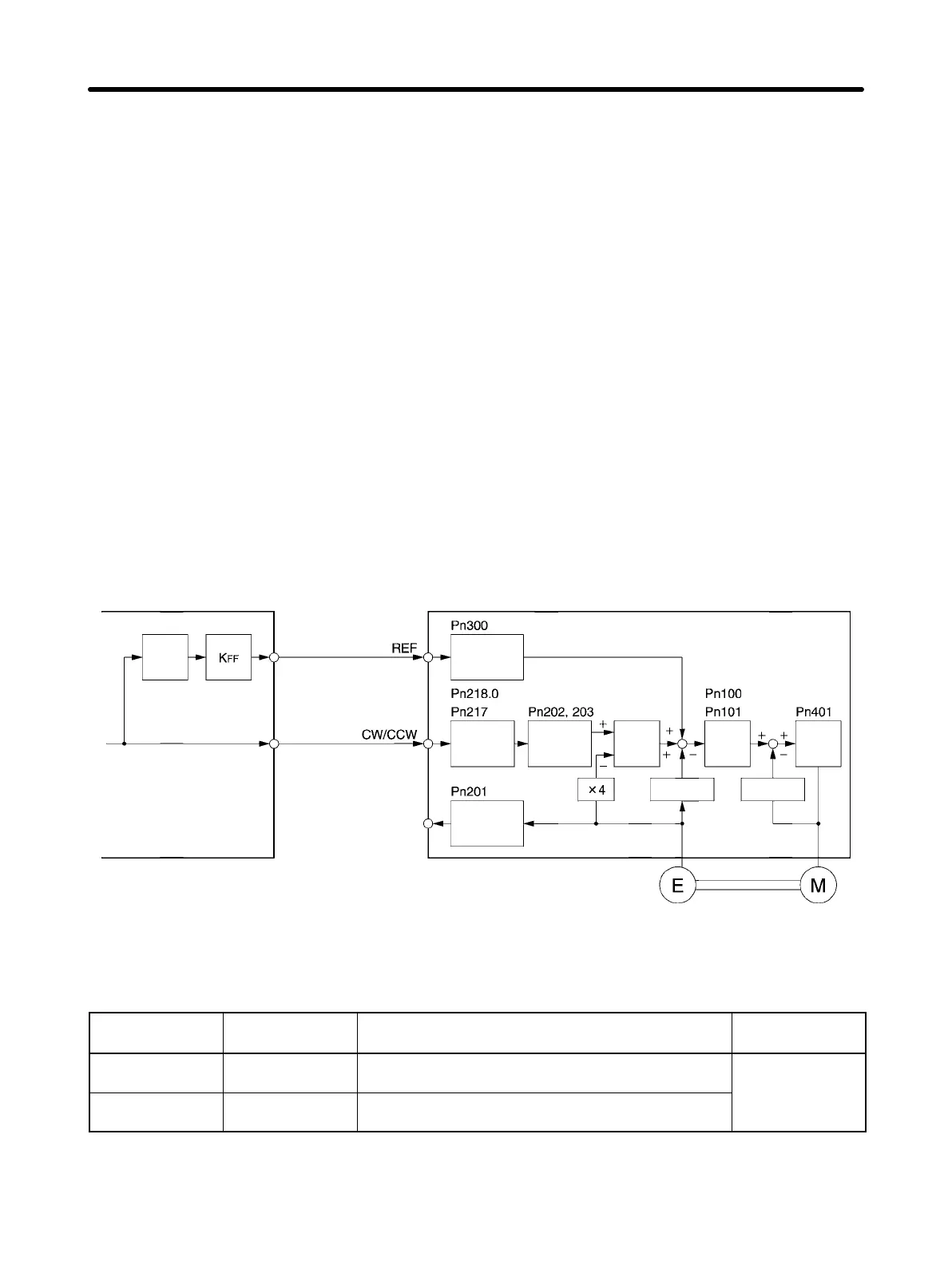

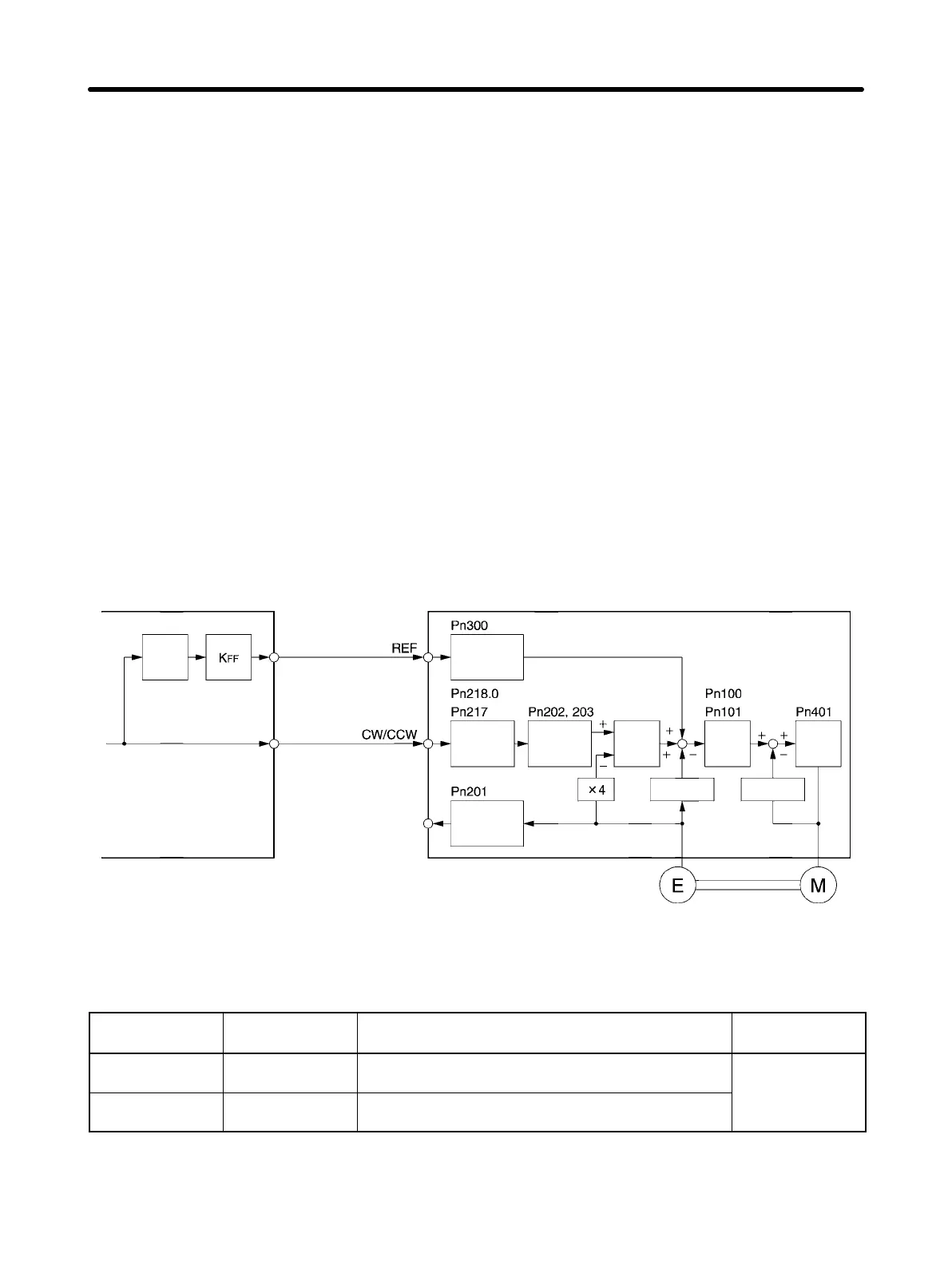

4-8-4 Speed Feed-forward Function (Position)

H Functions

• This function shortens positioning time by adding the REF (speed command input) value to the speed

loop.

• Normally, the differential value for the position command (pulse train command) is generated in the

controller, and input to REF.

• If the feed-forward amount (REF voltage) is too large, an overshoot may occur, so adjust Pn300

(speed command scale) as required.

Speed Feed-forward Function Block Diagram

Host Controller

Differ-

ential

Position command

Speed feed-forward

Command

pulses

Encoder output

Speed com-

mand scale

Electronic

gear ratio

(G1/G2)

Encoder di-

viding rate

Deviation

counter

Speed

detection

Current

detection

Current

loop

Speed

loop

Servo Driver

Command

pulse factor

H Parameters Requiring Settings

Parameter No. Parameter

name

Explanation Example

Pn207.1 Speed command

input switching

Set Pn207.1 to 1 (use REF as speed torque

feed-forward input).

4-4-4 Parameter

Details

Pn300 Speed command

scale

Adjust the speed feed-forward amount. (See note.)

Note The default setting is 1000 (x 0.01 V / rated number of revolutions).

Operation Chapter 4

Loading...

Loading...