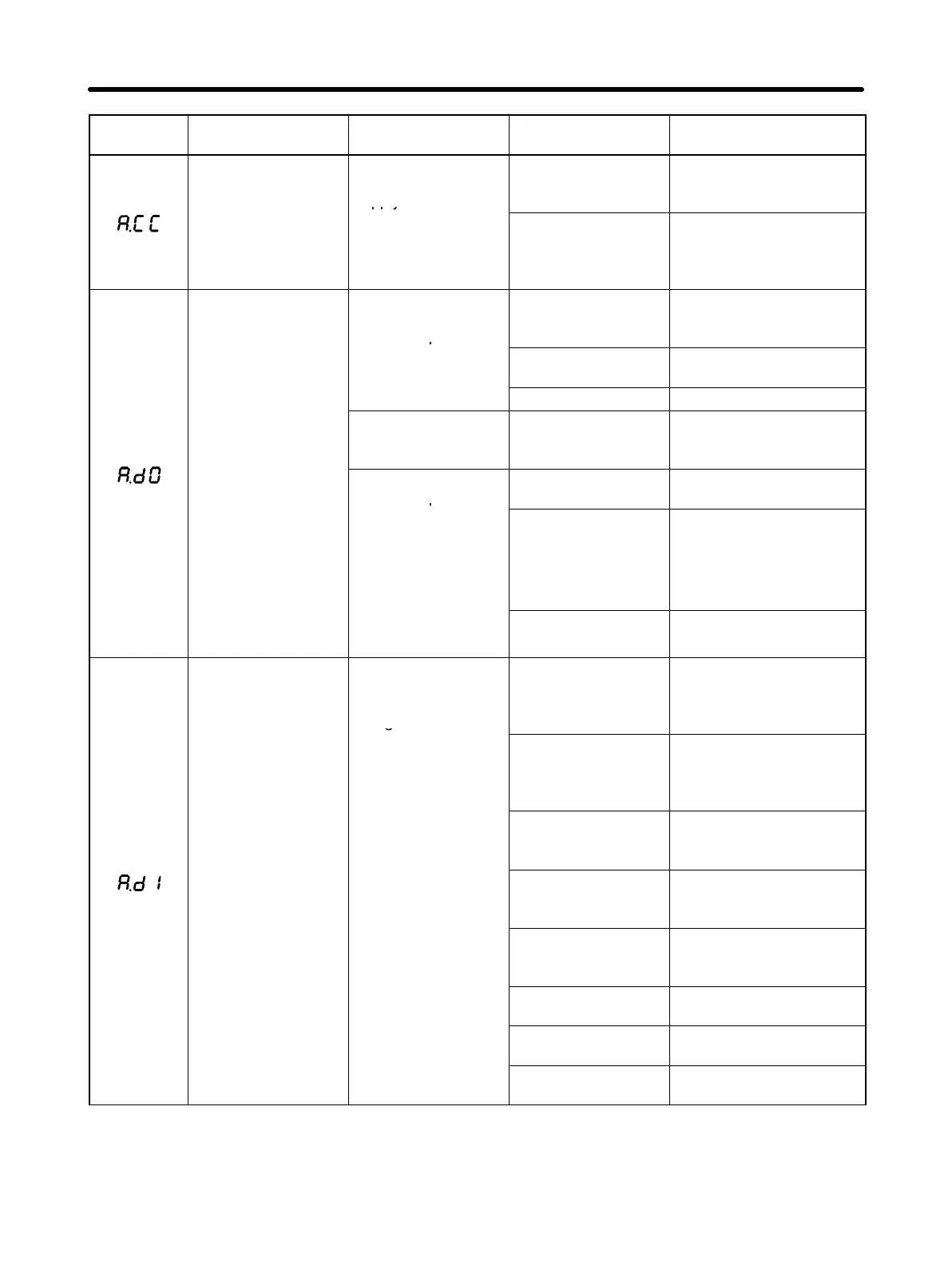

5-15

Display CountermeasuresCause of errorStatus when error

occurs

Error

Multi-turn limit mis-

match (ABS)

Occurs when the

control circuit power

supply is turned ON.

Pn205 (absolute en-

coder rotation limit

setting) changed.

Perform absolute encod-

er rotation limit setting

change (Fn013).

Pn205 (absolute en-

coder rotation limit

setting) changed by

mistake.

Set Pn205 correctly

Deviation counter

overflow

Servomotor will not

rotate even when

command pulses

Servomotor power

or encoder line is

wired incorrectly.

Rewire correctly.

are input.

Locked mechanical-

ly

Repair if the Servomotor

shaft is locked

Control panel error Replace the Servo Driver.

Occurs when rotat-

ing at high speed.

Servomotor power

or encoder line is

miswired.

Rewire correctly.

Occurs when long

command pulses

Gain adjustment is

insufficient.

Adjust the gain.

are sent.

Acceleration and de-

celeration is too vio-

lent.

Lengthen acceleration

and deceleration time.

Use position command

filter (Pn207.0, Pn204,

and Pn208).

Load is too large. Lighten the load.

Reselect the Servomotor.

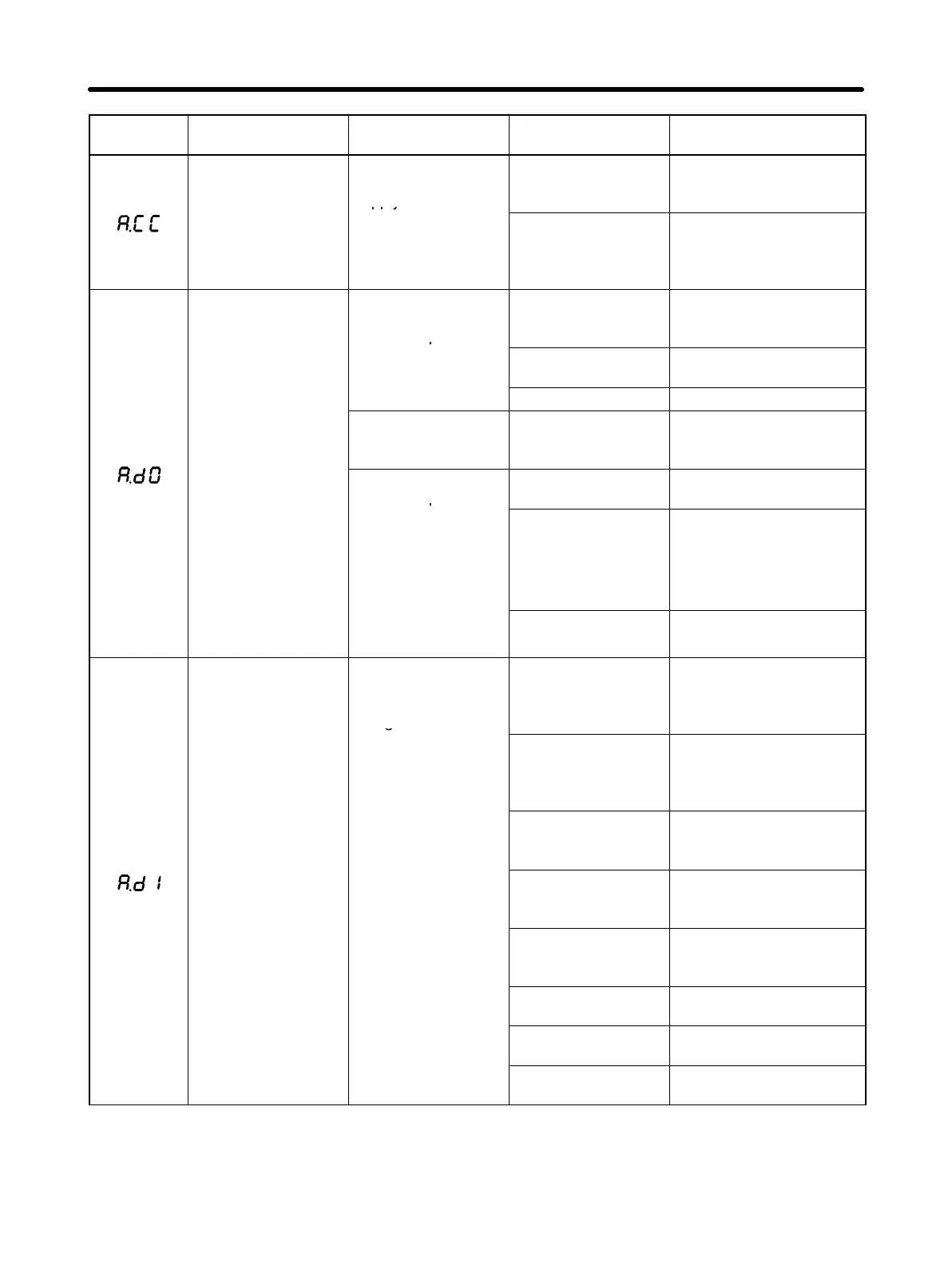

Motor-load deviation

over*

Occurs when the

motor or full closed-

loop encoder is ro-

tating.

Pn002.3 (fully-

closed encoder

usage method) is

not set correctly.

Correct the setting of

Pn002.3.

Pn206 (number of

fully-closed encoder

pulses) is not set

correctly.

Correct the setting of

Pn206.

Pn51A (motor-load

deviation over level)

is not set correctly.

Correct the setting of

Pn51A according to the

machinery.

The machinery is

not operating prop-

erly.

Check the machinery.

Slipping is occurring

in the power trans-

mission.

Set Pn51A to 0 so that

A.d1 is not detected.

Fully-closed encod-

er wiring error.

Wire the fully-closed en-

coder correctly.

Fully-closed encod-

er is defective.

Replace the fully-closed

encoder.

Option Unit is defec-

tive.

Replace the Option Unit.

Troubleshooting Chapter 5

Loading...

Loading...