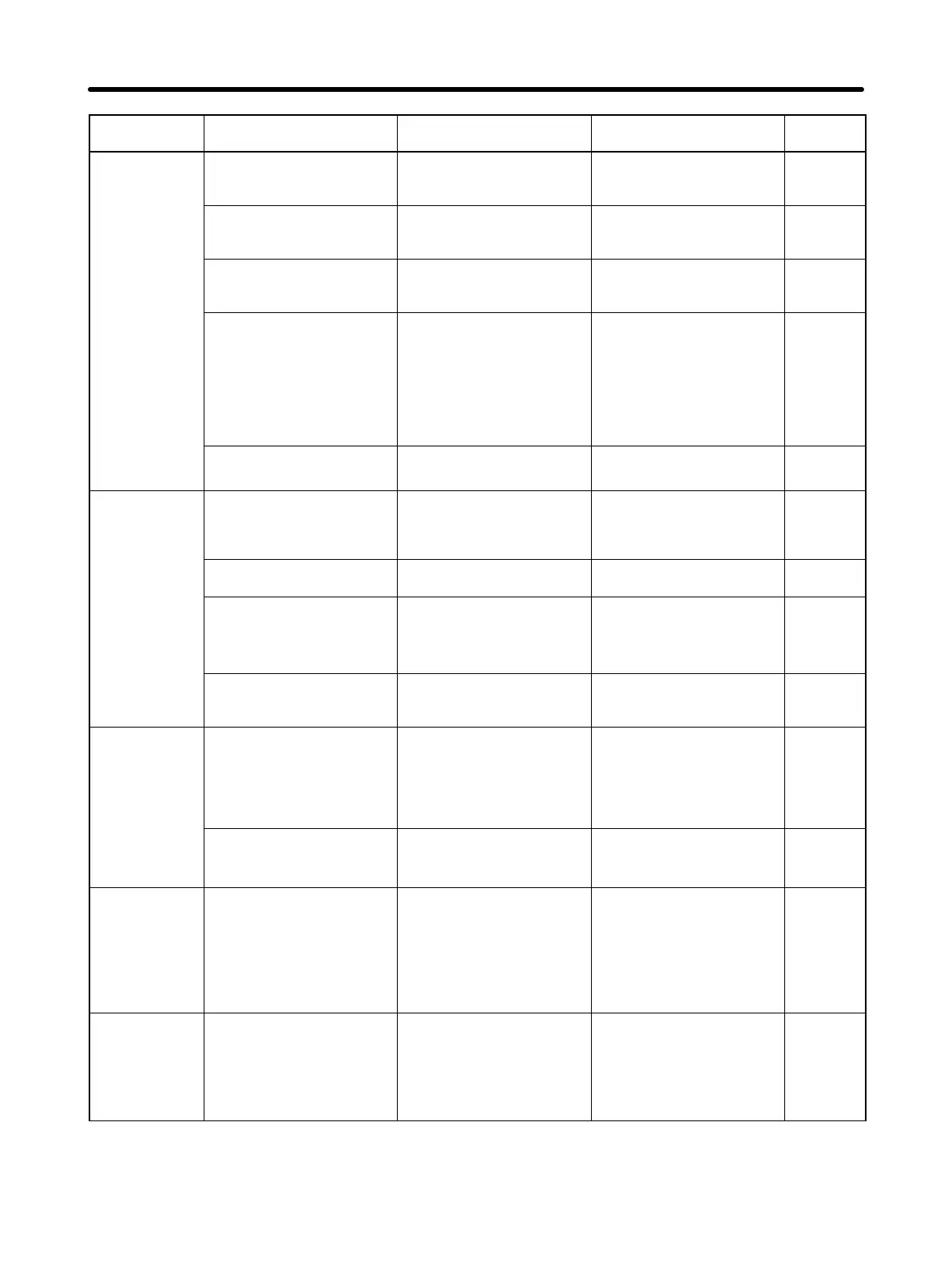

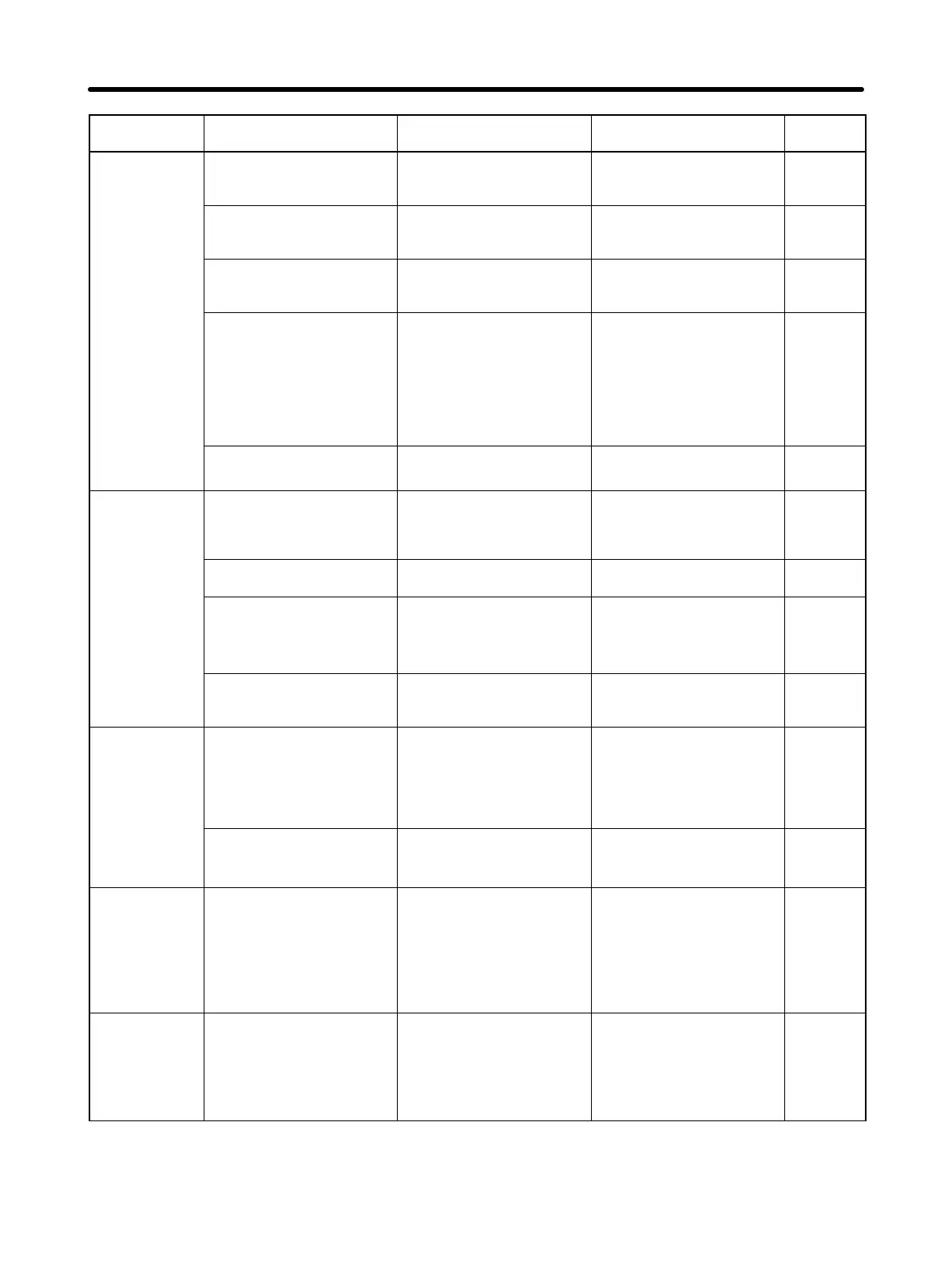

5-19

Symptom Control

mode

CountermeasuresItems to checkProbable cause

Servomotor op-

eration is unsta-

ble.

The Servomotor power lines

or encoder lines are wired

incorrectly.

Check the Servomotor pow-

er line U, V, and W phases,

and the encoder line wiring.

Correct the wiring. All modes

The bias function setting is

incorrect.

--- Adjust Pn107 (bias rotation-

al speed) and Pn108 (bias

addition width).

Position

The polarity of the speed

command (REF) input is

wrong.

Check the speed command

input wiring.

Correct the wiring. Speed

There are eccentricities or

looseness in the coupling

connecting the Servomotor

shaft and the mechanical

system, or there are load

torque fluctuations accord-

ing to how the pulley gears

are engaging.

Check the machinery.

Try operating the Servomo-

tor without a load.

Adjust the machinery. All modes

Gain is wrong. --- Use auto-tuning.

Adjust the gain manually.

Position

Speed

Servomotor is

overheating.

The ambient temperature is

too high.

Check to be sure that the

ambient temperature around

the Servomotor is no higher

than 40°C.

Lower the ambient tempera-

ture to 40°C or less. (Use a

cooler or fan.)

All modes

Ventilation is obstructed. Check to see whether any-

thing is blocking ventilation.

Ensure adequate ventila-

tion.

All modes

There is an overload. Check the torque command

value by means of monitor

mode (Un002).

Lighten the load.

Change to a larger capacity

Servomotor and Servo Driv-

er.

All modes

The correspondence be-

tween the Servo Driver and

the Servomotor is incorrect.

Check the models. Combine models that corre-

spond correctly.

All modes

There are un-

usual noises.

The machinery is vibrating. Inspect the machinery to

see whether there are any

foreign objects in the mov-

able parts, or whether there

is any damage, deforma-

tion, or looseness.

Fix any problems causing

vibration.

All modes

Pn100 (Speed loop gain) is

insufficient.

--- Use online auto-tuning.

Adjust the gain manually

(speed loop gain).

Position

Speed

Vibration is oc-

curring at the

same frequency

as the applica-

ble power sup-

ply.

Inductive noise is occurring. Check to see whether the

Servo Driver control signal

lines are too long.

Check to see whether con-

trol signal lines and power

supply lines are too close to

each other.

Shorten the control signal

lines.

Separate control signal lines

from power supply lines.

Use a low-impedance pow-

er supply for control signals.

All modes

The Servomo-

tor operates

even when

speed com-

mand is for 0 V.

The speed command volt-

age and the speed com-

mand input section are off-

set.

Check the speed command

voltage.

Adjust the speed command

offset (Fn009 or Fn00A).

Use speed control mode

with position lock function.

(Control mode selection:

Pn000.1 = A)

Speed

Troubleshooting Chapter 5

Loading...

Loading...