-----------------------

blow to wedge the new valve seat securely in

place. The valve seat must be staked to en-

sure

a tight fit and eliminate the danger of its

loosening in the bore. Before installing the

valves, refinish the valve seat inserts.

Valve Tappets

The engine is equipped with adjustable valve tap-

pets. Adjust the valve clearance only when the en-

gine is at ambient temperature.

Tappet Adjustment Procedure

1 . Remove all parts that block access to the valve

tappets.

2. Remove the spark plugs, to make turning the

engine easier.

3. Place a socket wrench on the flywheel

capscrew, and rotate the crankshaft in

a clock-

wise direction until the left intake valve (viewed

from flywheel end) opens and closes. Con-

tinue turning the crankshaft until the TDC mark

on the flywheel is lined up with the TDC mark

on the gear cover. This should place the left

piston (#1) at the top of its compression stroke.

Verify that the left intake and exhaust valves

are closed and that there is no pressure on the

valve lifters.

4.

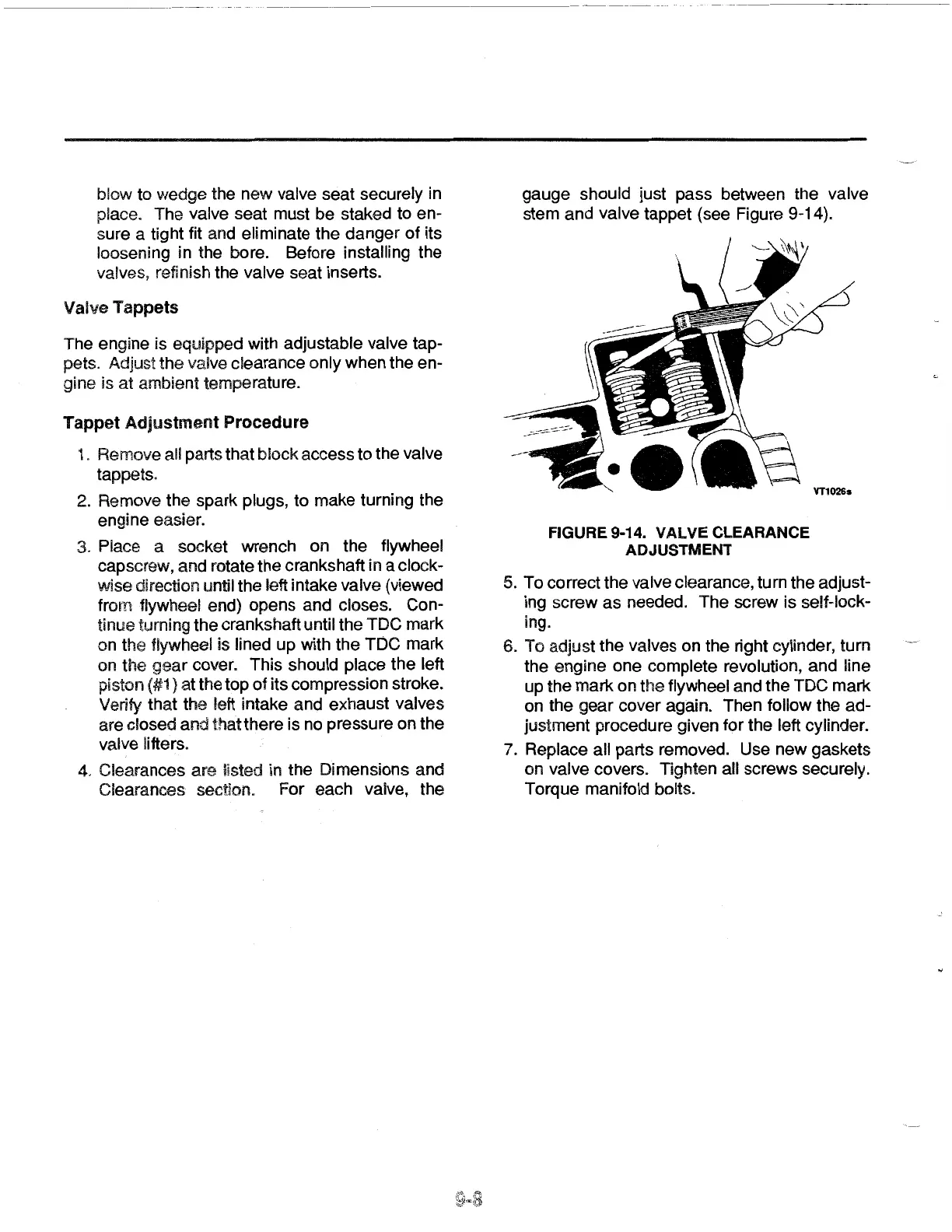

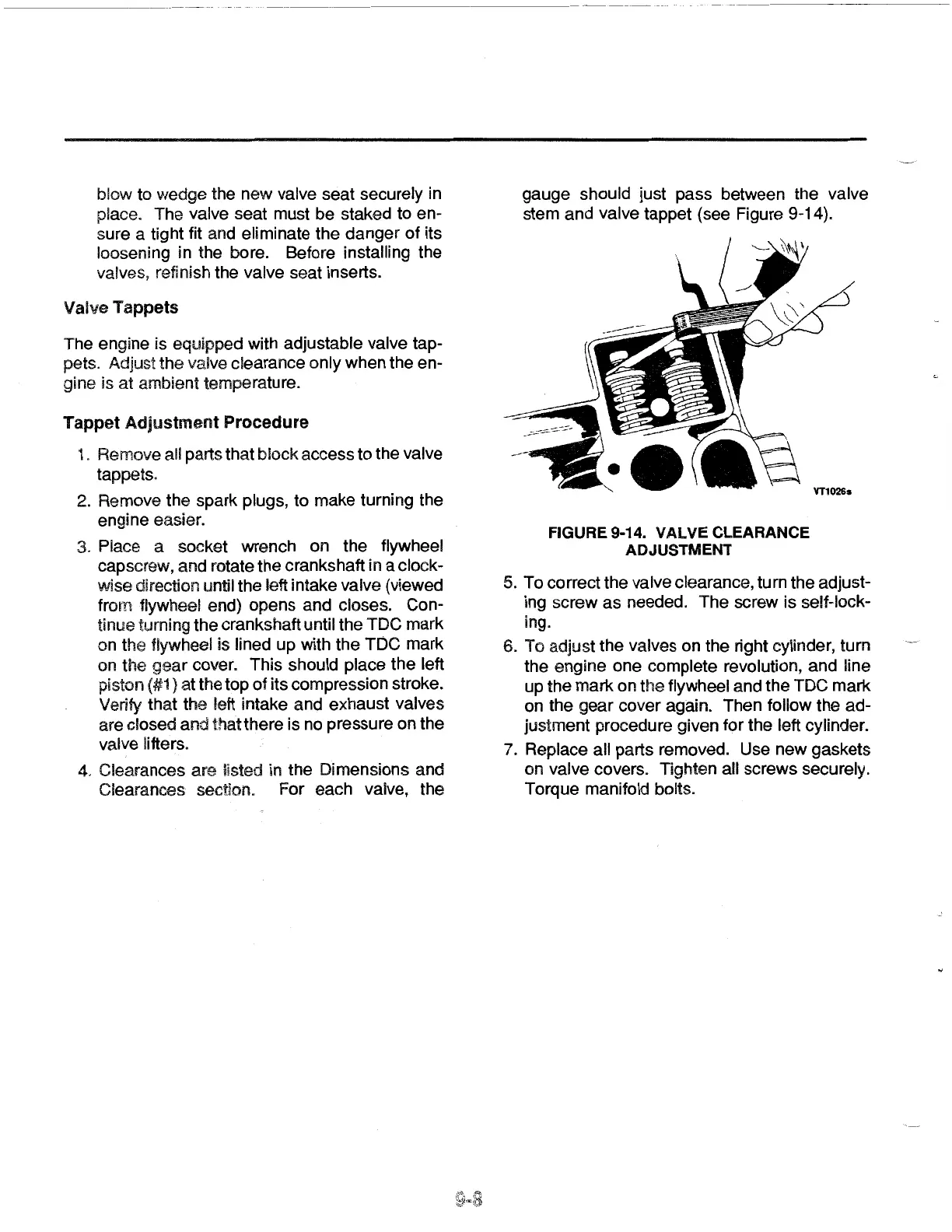

Clearances are listed in the Dimensions and

Clearances section. For each valve, the

gauge should just pass between the valve

stem and valve tappet (see Figure 9-14).

FIGURE 9-14. VALVE CLEARANCE

ADJUSTMENT

5. To correct the valve clearance, turn the adjust-

ing screw as needed. The screw is self-lock-

ing.

6. To adjust the valves on the right cylinder, turn

the engine one complete revolution, and line

up the mark on the flywheel and the TDC mark

on the gear cover again. Then follow the ad-

justment procedure given for the left cylinder.

7.

Replace all parts removed. Use new gaskets

on valve covers. Tighten all screws securely.

Torque manifold bolts.

Loading...

Loading...