PISTON ASSEMBLY

The piston assembly consists of:

• Piston

• Piston rings

• Piston pin

• Connecting rod assembly and bearing

After removal from the engine, all parts must be

carefully inspected for damage and wear before

they are replaced.

Piston

Removal

and

Disassembly

Procedure

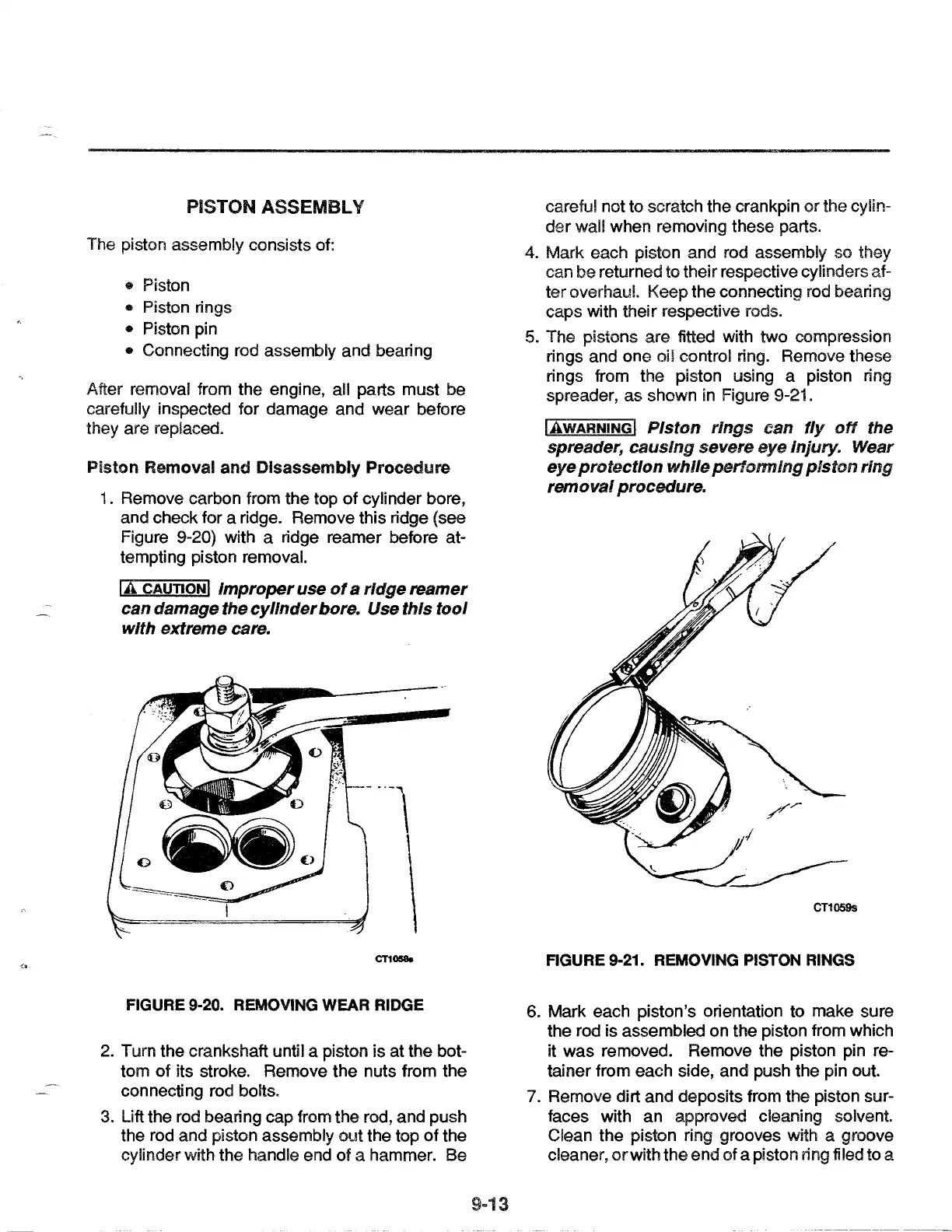

1. Remove carbon from the top

of

cylinder bore,

and check for a ridge. Remove this ridge (see

Figure

9-20) with a ridge reamer before at-

tempting piston removal.

lA CAUTION I

Improper

use

of

a ridge reamer

can damage the

cylinder

bore. Use this

tool

with extreme care.

CT105&

FIGURE 9-20. REMOVING WEAR RIDGE

2. Turn the crankshaft until a piston is

at

the bot-

tom

of

its stroke. Remove

the

nuts from the

connecting rod bolts.

3. Lift the rod bearing cap from the rod, and push

the rod and piston assembly

out

the top

of

the

cylinder with the handle end

of

a hammer. Be

9-13

careful not to scratch the crankpin

or

the cylin-

der

wall when removing these parts.

4. Mark each piston and rod assembly so they

can

be

returned to their respective cylinders af-

ter overhaul. Keep

the

connecting rod bearing

caps with their respective rods.

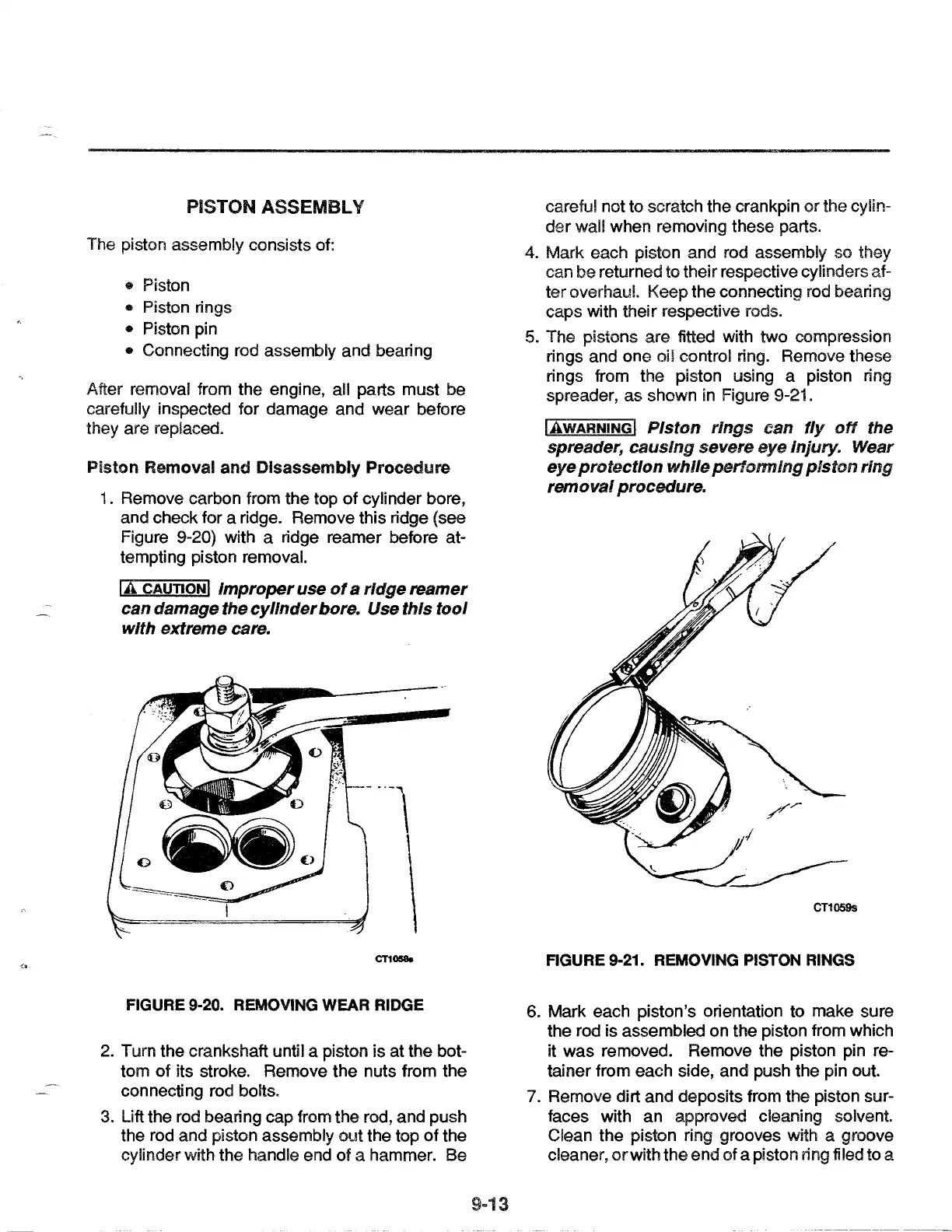

5. The pistons are fitted with

two

compression

rings and

one

oil control ring. Remove these

rings from the piston using a piston ring

spreader,

as

shown in Figure 9-21.

IAwARNINGI

Piston rings can

fly

off

the

spreader, causing severe eye injury. Wear

eye

protection

while

performing

piston

ring

removal procedure.

CT1059s

FIGURE 9-21. REMOVING PISTON RINGS

6.

Mark

each piston's orientation to make sure

the rod is assembled

on

the piston from which

it

was

removed. Remove the piston pin re-

tainer from each side, and push the pin out.

7. Remove dirt

and

deposits from the piston sur-

faces with

an

approved cleaning solvent.

Clean the piston ring grooves with a groove

cleaner,

or

with

the

end

of

a piston ring filed to a

Loading...

Loading...