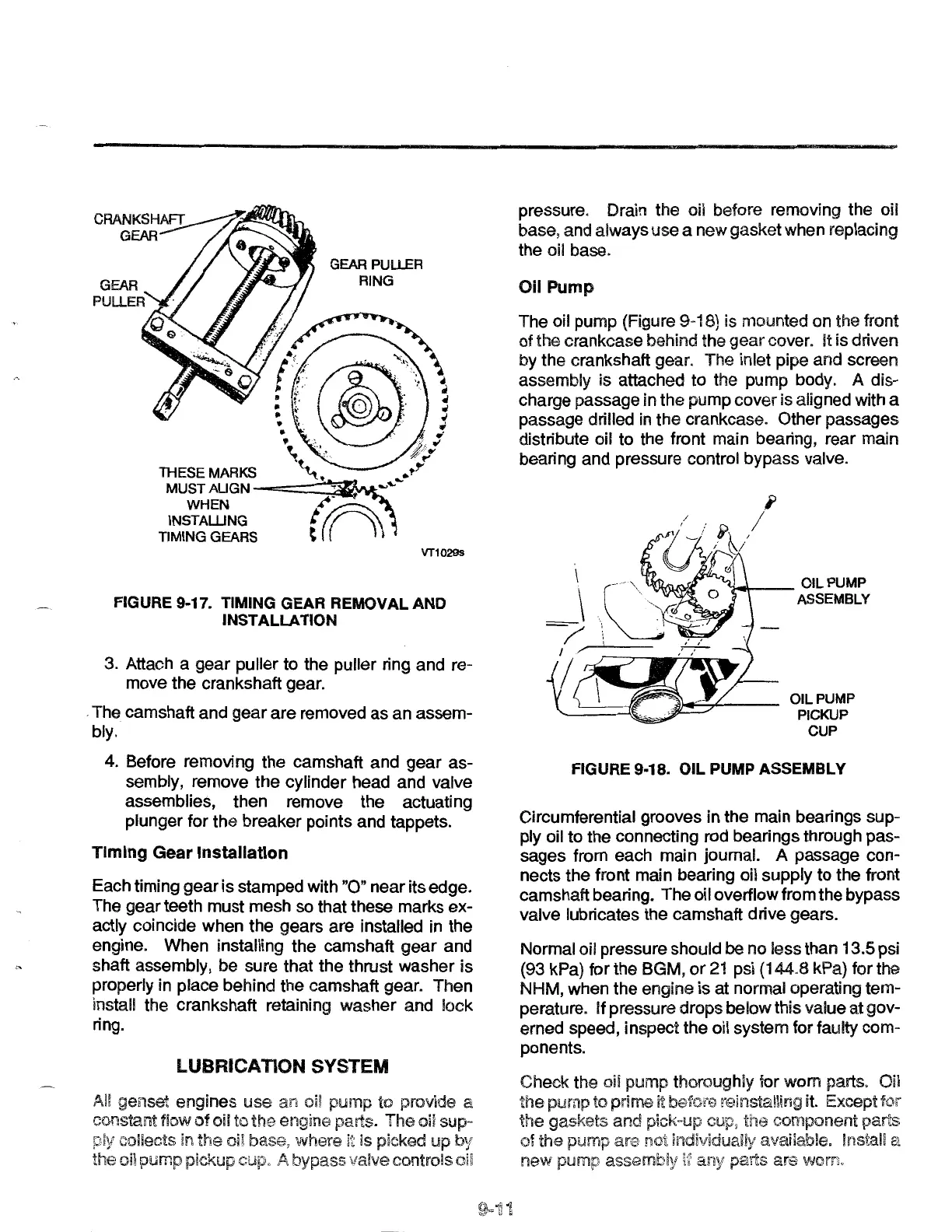

GEARPUUER

RING

VT1029s

FIGURE 9-11. TIMING GEAR REMOVAL AND

INSTALLATION

3. Attach a

gear

puller to the puller ring and re-

move the crankshaft gear.

. The camshaft and

gear

are removed

as

an assem-

bly.

4. Before removing the camshaft and

gear

as-

sembly, remove the cylinder head and valve

assemblies, then remove the actuating

plunger for the breaker points and tappets.

Timing Gear Installation

Each timing

gear

is

stamped with

"0"

near its edge.

The gear teeth must mesh so that these marks ex-

actly coincide when the gears are installed in the

engine. When installing the camshaft

gear

and

shaft assembly, be sure that the thrust washer

is

properly in place behind the camshaft gear. Then

install the crankshaft retaining

washer

and lock

ring.

LUBRICATION SYSTEM

AI! genset engines

use

an

oil pump to provide a

constant flow

of

oil to engine parts. The oil sup-

collects in the oil base,

where~~

is picked up

by

the oil pump pickup A bypass vaive controls

pressure. Drain the oil before removing the oil

base, and always use a new gasket when replacing

the oil base.

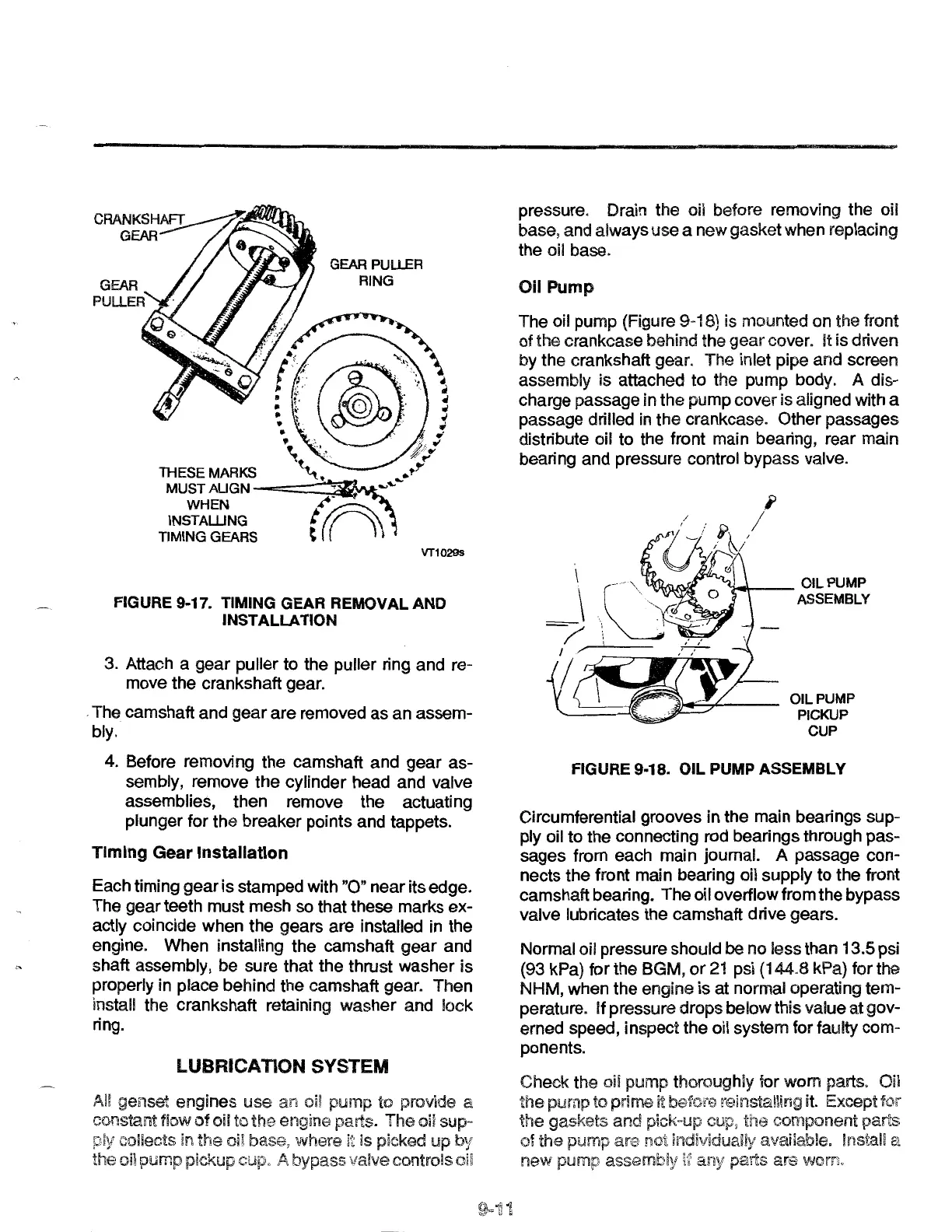

Oil Pump

The oil pump (Figure 9-18) is mounted on the front

of

the crankcase behind the

gear

cover. It is driven

by the crankshaft gear. The inlet pipe and screen

assembly is attached

to

the pump body. A dis-

charge passage in

the

pump

cover

is aligned with a

passage drilled in the crankcase. Other passages

distribute oil

to

the front main bearing, rear main

bearing and pressure control bypass valve.

OIL PUMP

PICKUP

CUP

FIGURE 9-18. OIL PUMP ASSEMBLY

Circumferential grooves in the main bearings sup-

ply oil

to

the connecting rod bearings through pas-

sages from each main journal. A passage con-

nects the front main bearing oil supply

to

the front

camshaft bearing. The oil overflow from the bypass

valve lubricates the camshaft drive gears.

Normal oil pressure should be no less than

13.5 psi

(93 kPa) for the BGM,

or

21

psi (144.8 kPa) for the

NHM, when the engine is at normal operating tem-

perature. If pressure drops below this value at gov-

erned speed, inspect the oil system for faulty com-

ponents.

Check the oil pump thoroughly for worn parts. Oil

the pump to prime it before reinstalling

it.

Except for

the gaskets and pick-up cup, component parts

of the pump are indivlduaJiy available. Install a

new pump assembly

I'~

parts are

worrt

Loading...

Loading...