Section

9.

Engine Block Assembly

GENERAL

The engine block assembly includes:

• Pistons and connecting rods

• Crankshaft

•Camshaft

• Valves and lifters

• Cylinder heads

• Lubrication system

• Timing gears

• Governor mechanism (mechanical)

•Bearings

• Cylinder block

Performing major service on the block assembly re-

quires that the genset

be

removed from the vehicle

(see

Set Removal section}. The control, generator,

electronic governor actuator, and all primary en-

gine systems must also

be

removed for complete

access to the block assembly. Refer to the previ-

ous sections for disassembly and removal proce-

dures.

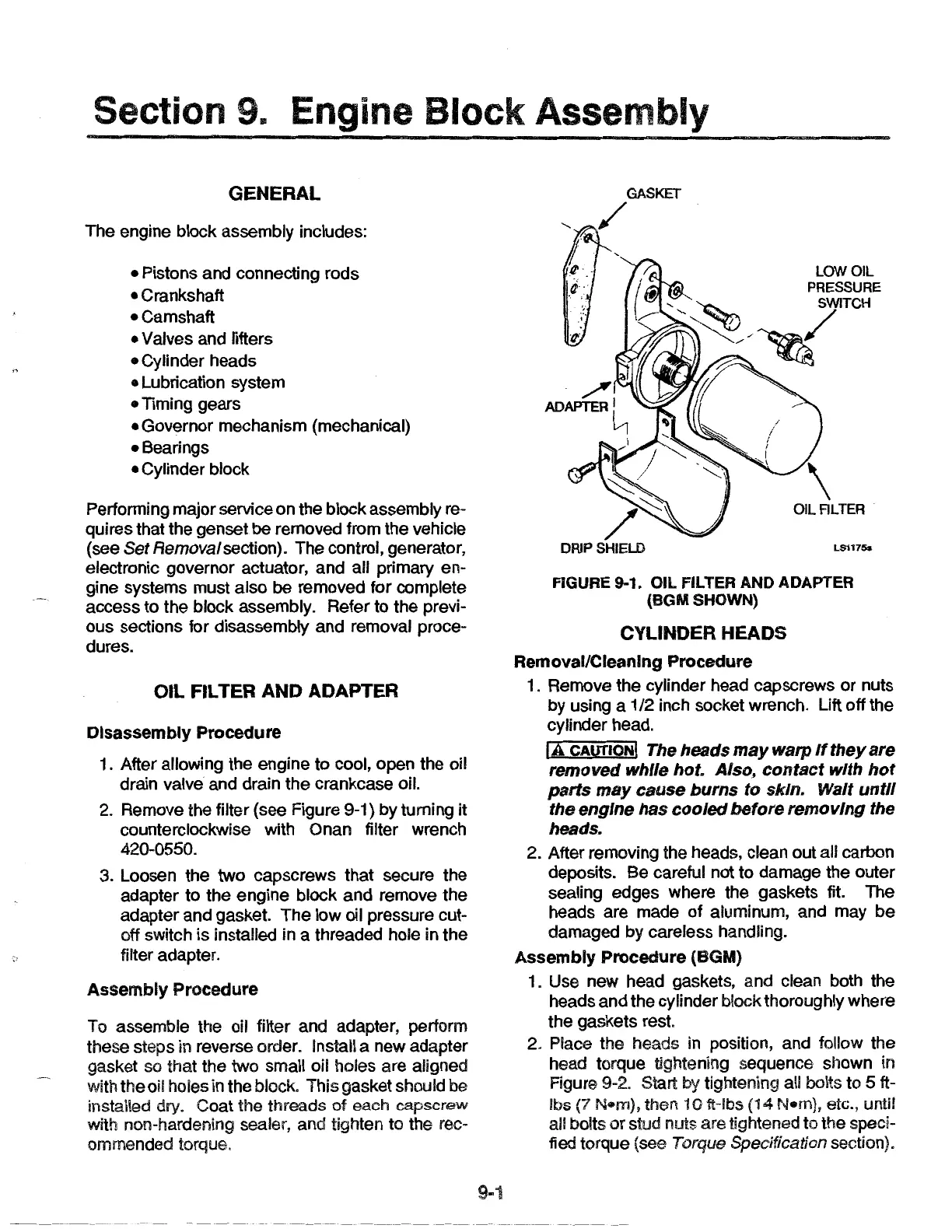

OIL FILTER AND ADAPTER

Disassembly

Procedure

1. After allowing the engine

to

cool, open the oil

drain valve and drain the crankcase oil.

2. Remove the filter (see Figure 9-1) by turning it

counterclockwise with Onan filter wrench

420-0550.

3. Loosen the two capscrews that secure the

adapter to the engine block and remove the

adapter and gasket. The low oil pressure cut-

off switch is installed in a threaded hole in the

filter adapter.

Assembly

Procedure

To assemble the oil filter and adapter, perform

these steps in reverse order. Install a new adapter

gasket

so that the two small oil holes are aligned

with the oil holes

in the block. This gasket should be

installed dry. Coat the threads of

each

capscrew

with non-hardening sealer, and tighten to the rec-

ommended torque.

9-1

OIL ALTER

LS1175s

FIGURE 9-1. OIL FILTER AND ADAPTER

(BGMSHOWN)

CYLINDER HEADS

Removal/Cleaning

Procedure

1. Remove the cylinder head capscrews

or

nuts

by using a

1/2 inch socket wrench. Lift off the

cylinder head.

lA

CAUTION

I The heads

may

warp

If

they

are

removed while hot. Also,

contact

with

hot

parts

may

cause

burns

to skin. Walt

until

the engine has

cooled

before removing the

heads.

2. After removing the heads, clean out all carbon

deposits. Be careful not to damage the outer

sealing edges where the gaskets fit. The

heads are made

of

aluminum, and may be

damaged by careless handling.

Assembly

Procedure

(BGM)

1. Use new head gaskets, and clean both the

heads and the cylinder block thoroughly where

the gaskets rest.

2. Place the heads in position, and follow the

head torque tightening sequence shown in

Figure

9-2. Start by tightening all bolts to 5 ft-

lbs {7

N•m),

then

10

fHbs

(14

N•m),

etc., until

all bolts

or

stud nuts are tightened to the speci-

fied torque (see

Torque Specification section).

Loading...

Loading...