5.

Install the bearing cap on the rod. Install one

fastener and tighten to 5 ft-lbs

{7

N•m).

Re-

peat this for the other fastener. Tighten both

fasteners to 14 ft-lbs (19 N•m).

6. Install the remaining piston and rod in the

same way. Crank the engine by hand, to see

that all bearings are free.

Rod Bearing Clearance Procedure

1. Mark all parts so they can be installed in their

original positions, and wipe all parts clean of oil

and grease.

2.

Place a piece of the correct size Plasti-gage

across the full width

of

the bearing cap, about

1/4 inch

(6

mm) off-center.

3.

Install the bearing cap, and tighten to the

specified torque.

Do

not rotate the crankshaft

after the cap is in place.

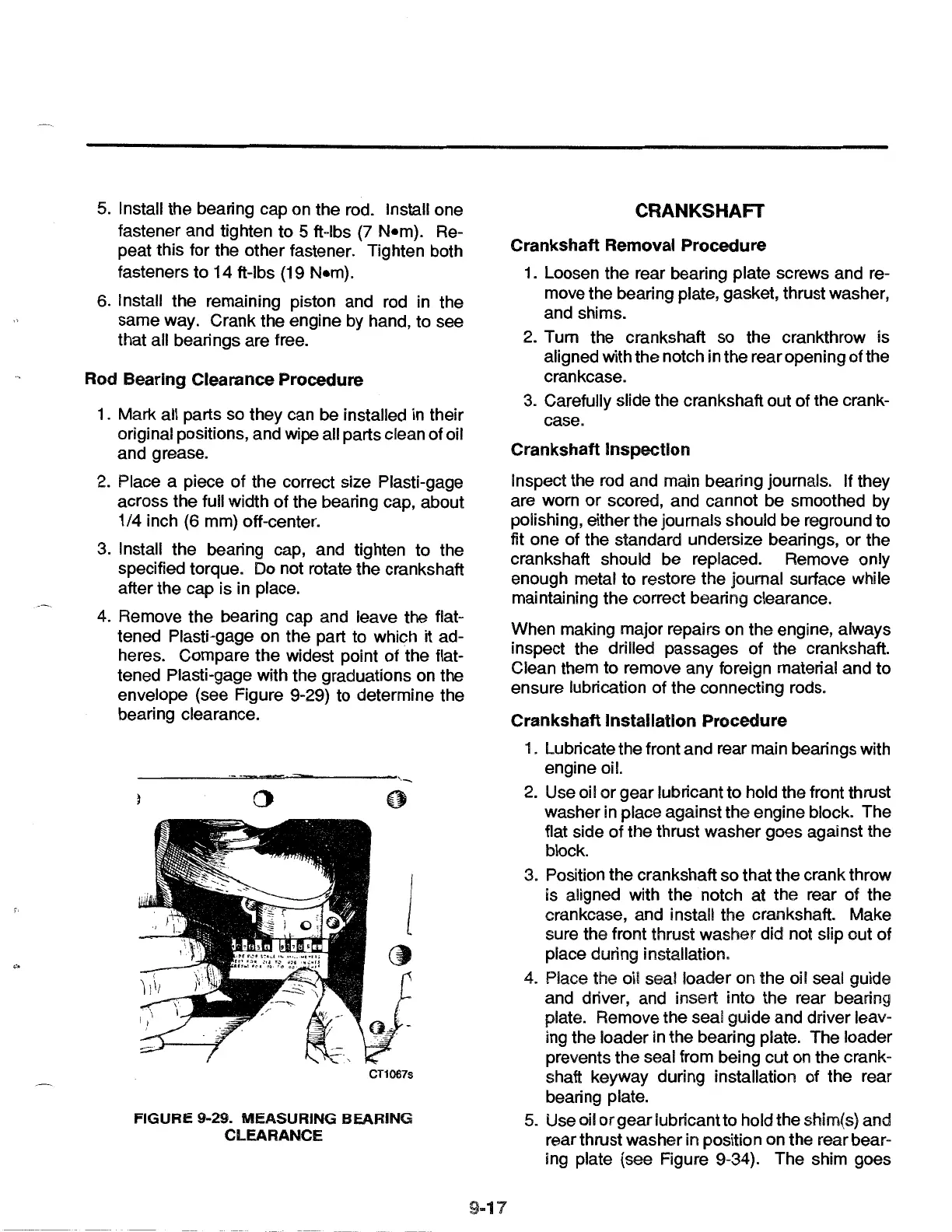

4.

Remove the bearing cap and leave the flat-

tened Plasti-gage on the part to which it ad-

heres. Compare the widest point of the flat-

tened Plasti-gage with the graduations on the

envelope (see Figure 9-29) to determine the

bearing clearance.

----~=--

......

:.....=-----'-~

()

CT1067s

FIGURE

9-29.

MEASURING

BEARING

CLEARANCE

9-17

CRANKSHAFT

Crankshaft Removal Procedure

1. Loosen the rear bearing plate screws and re-

move the bearing plate, gasket, thrust washer,

and shims.

2. Tum the crankshaft so the crankthrow is

aligned with the notch in the rear opening ofthe

crankcase.

3.

Carefully slide the crankshaft out of the crank-

case.

Crankshaft Inspection

Inspect the

rod

and main bearing journals. If they

are worn

or

scored, and cannot be smoothed by

polishing, either the journals should be reground to

fit one of the standard undersize bearings, or the

crankshaft should be replaced. Remove only

enough metal to restore the journal surface while

maintaining the correct bearing clearance.

When making major repairs on the engine, always

inspect the drilled passages of the crankshaft.

Clean them to remove any foreign material and to

ensure lubrication of the connecting rods.

Crankshaft Installation Procedure

1.

Lubricate the front and rear main bearings with

engine oil.

2.

Use oil or gear lubricant to hold the front thrust

washer

in

place against the engine block. The

flat side

of

the thrust washer goes against the

block.

3. Position the crankshaft so that the crank throw

is aligned with the notch at the rear of the

crankcase, and install the crankshaft. Make

sure the front thrust washer did not slip out of

place during installation.

4.

Place the oil seal loader on the oil seal guide

and driver, and insert into the rear bearing

plate. Remove the seal guide and driver leav-

ing the loader

in

the bearing plate. The loader

prevents the seal from being cut

on

the crank-

shaft keyway during installation of the rear

bearing plate.

5.

Use oil

or

gear lubricant to hold the shim(s) and

rear thrust washer in position on the rear bear-

ing plate (see Figure 9-34). The shim goes

Loading...

Loading...