2. Position the piston on the connecting rod. In-

stall the piston pin. The piston pin is a full-float-

ing type, and must be kept in place (in the pis-

ton) with two lock rings,

one

at each side. In-

stall the lock rings and ensure they are prop-

erly in place before installing

the

piston and

connecting rod in the engine.

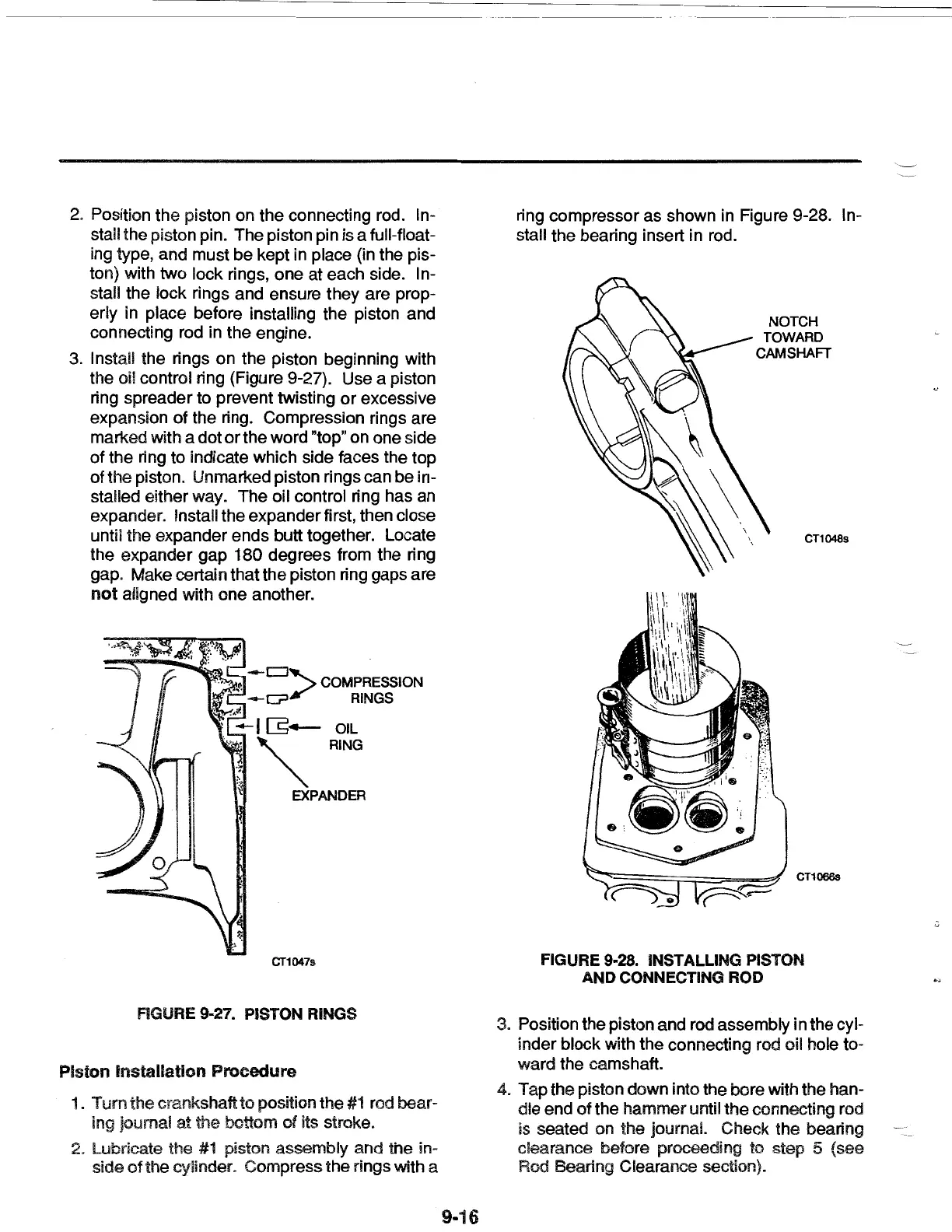

3. Install the rings

on

the piston beginning with

the oi! control ring (Figure 9-27). Use a piston

ring spreader to prevent twisting

or

excessive

expansion

of

the ring. Compression rings are

marked with a

dot

or

the word "top" on one side

of

the ring to indicate which side faces the top

of

the piston. Unmarked piston rings can be in-

stalled either way. The oil control ring has an

expander. Install the

expander

first, then close

until the

expander

ends

butt together. Locate

the expander

gap

180 degrees from the ring

gap. Make certain that the piston ring gaps are

not

aligned with

one

another.

EXPANDER

CT1047s

RGURE

9-27. PISTON RINGS

Piston Installation Procedure

1. Turn

the

crankshaft

to

position

the

#1

rod bear-

ing journal

at

the bottom

of

its stroke.

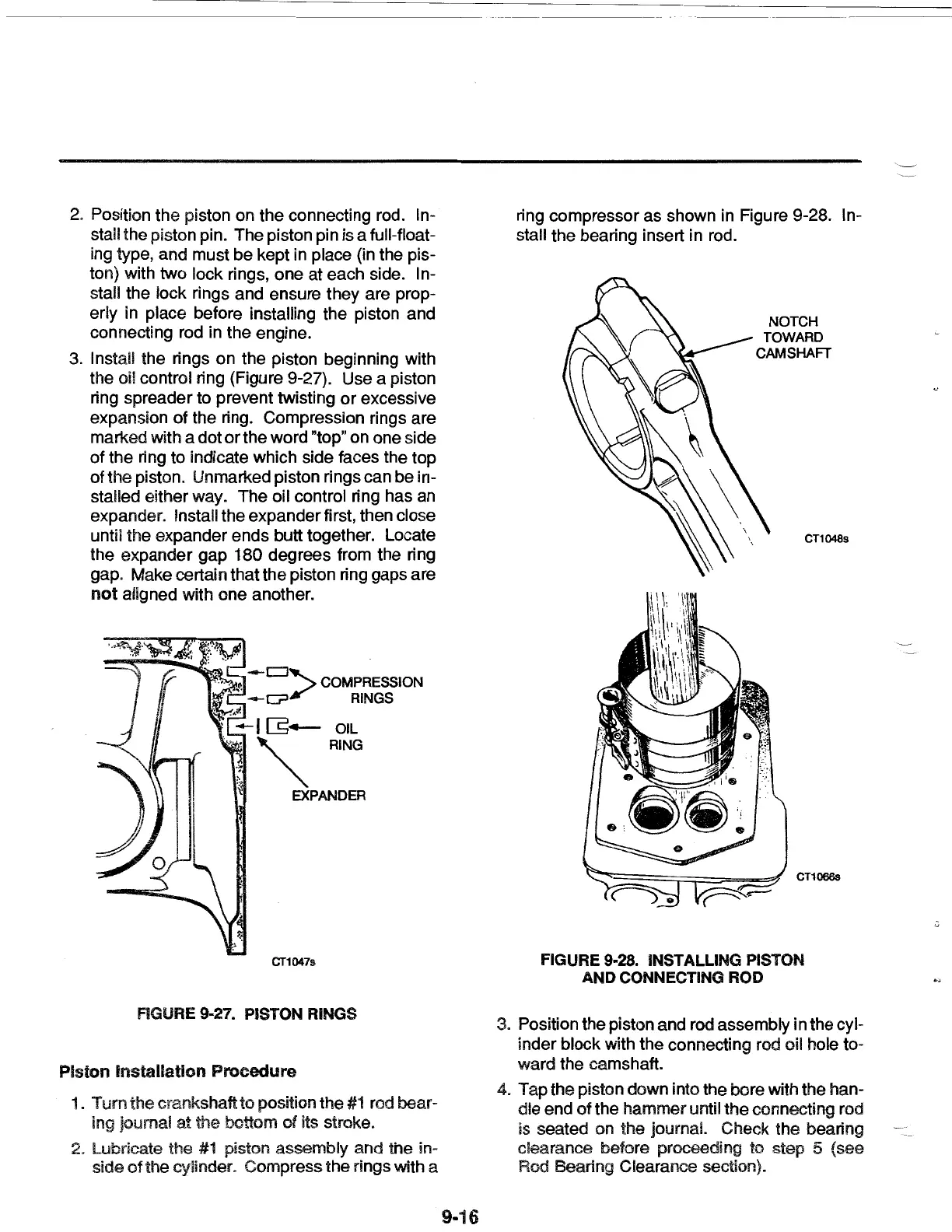

2. Lubricate

the

#1

piston assembly and the in-

side

ofthe

cylinder. Compress the rings with a

9-16

ring compressor as shown in Figure 9-28. In-

stall the bearing insert in rod.

NOTCH

TOWARD

CAMSHAFT

CT1048s

CT1066s

FIGURE 9-28. INSTALLING PISTON

AND CONNECTING ROD

3. Position

the

piston and rod assembly in the cyl-

inder block with the connecting rod

oil hole to-

ward

the

camshaft.

4. Tap

the

piston down into the bore with the han-

dle

end

of

the

hammer

until

the

connecting rod

is seated on the journal. Check

the

bearing

clearance before proceeding

to

step 5 (see

Rod Bearing Clearance section}.

Loading...

Loading...